Preparation method of hydrogel flexible strain sensor with resistance-capacitance dual modes and sensor

A strain sensor, hydrogel technology, applied in chemical instruments and methods, electrical/magnetic solid deformation measurement, electromagnetic measurement devices, etc., can solve problems such as sensor failure, inability to meet stress, and shorten sensor life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1 Hydrogel Flexible Strain Sensor with Resistance and Capacitance Dual Modes

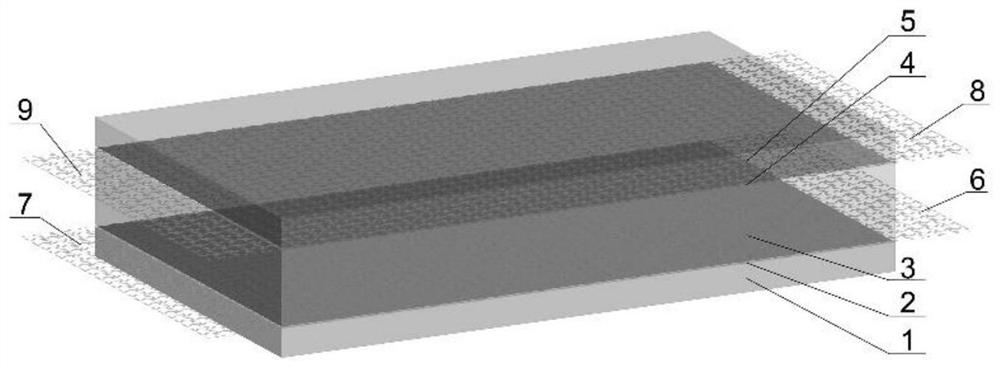

[0057] The sensor prepared in this embodiment includes the upper glue layer 5, the middle glue layer 3 and the lower glue layer 1 of the same shape; the upper grid electrode 4 is arranged between the upper glue layer 5 and the middle glue layer 3, and the lower glue layer 1 and the middle glue layer The lower grid electrode 2 is arranged between the layers 3; the wide side of the upper grid electrode 4 matches the width of the intermediate adhesive layer 3, and the long side extends to the outside of the long sides on both sides of the intermediate adhesive layer 3; the lower grid electrode 2 The shape is the same as that of the upper grid electrode 4; the outer surface of the sensor is provided with a flexible polymer film encapsulation layer.

[0058] The sensor preparation method is as follows:

[0059] Step (1), dissolve 15.6g of acrylamide monomer and 17.5g of sodium chloride in...

Embodiment 2

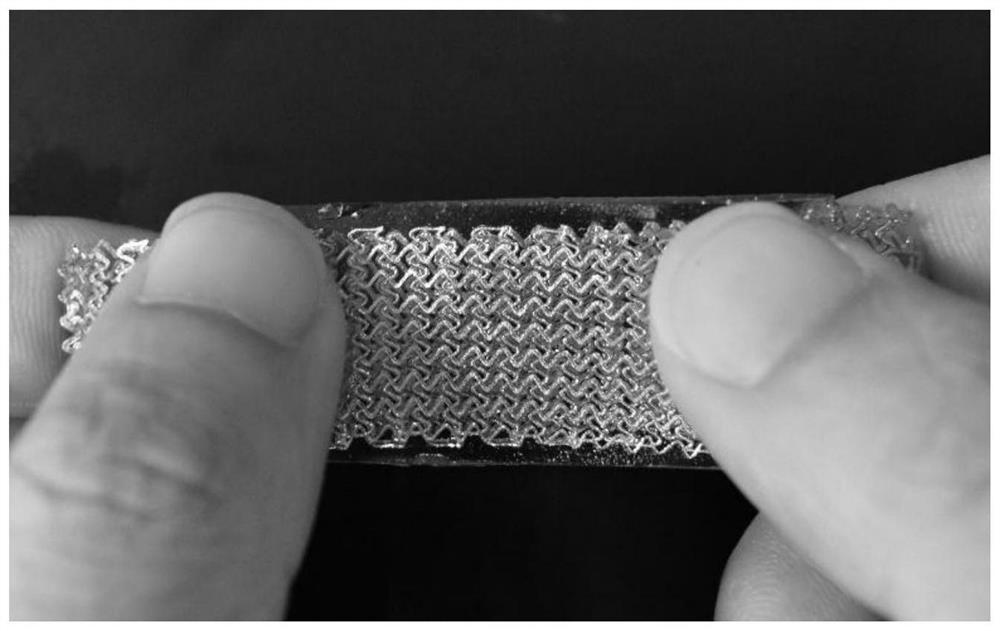

[0072] The sensor preparation method of this embodiment is the same as that of Embodiment 1, except that the thickness of the lower rubber layer in this embodiment is 0.5 mm, the thickness of the middle rubber layer is 1 mm, and the thickness of the upper rubber layer is 0.5 mm. The structure of the upper grid electrode and the lower grid electrode is as follows Figure 7 As shown, it is a spring-like connection grid structure, which is made of thermoplastic polyurethane, with a line width of 20 μm and a thickness of 50 μm. The thickness of the metal chromium layer evaporated on the surface is 5 nm, and the thickness of the gold layer is 25 nm.

[0073] In this embodiment, the lengths of the lead electrodes 6-9 (that is, the parts on both sides of the long sides of the upper / lower grid electrodes that exceed the long sides of the intermediate adhesive layer) are all 1 cm.

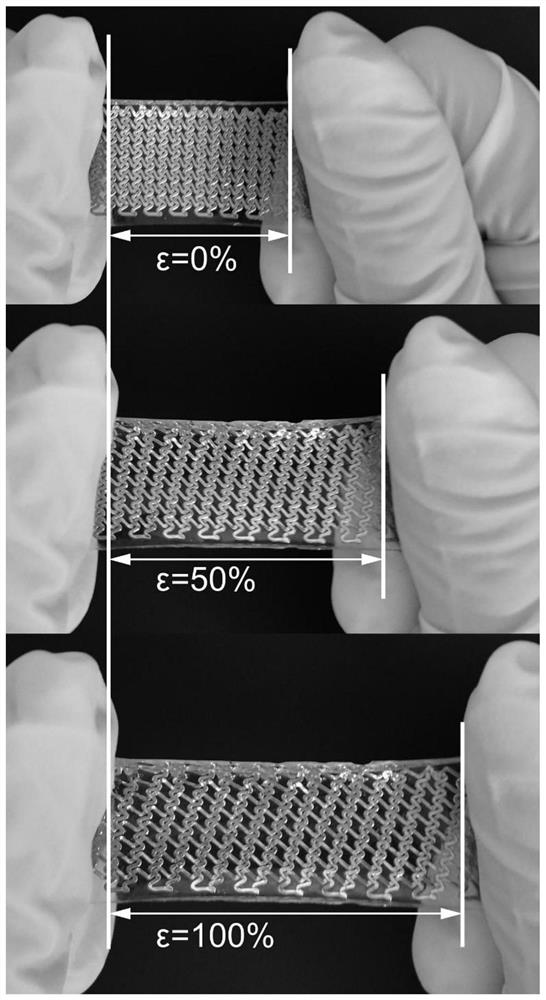

[0074] Referring to the method of Example 1, the hydrogel flexible strain sensor with resistance-capacit...

Embodiment 3

[0076] The sensor preparation method of this embodiment is the same as that of Embodiment 1, and the difference from Embodiment 1 is that the structure of the upper grid electrode and the lower grid electrode of this embodiment is as follows Figure 8 As shown, it is a spring-like connection grid structure, which is made of thermoplastic polyurethane, with a line width of 500 μm and a thickness of 200 μm. The thickness of the evaporated metal titanium layer on the surface is 20 nm, and the thickness of the gold layer is 100 nm.

[0077] Referring to the method of Example 1, the hydrogel flexible strain sensor with resistance-capacitance dual mode obtained in this example is tested. When the tensile strain is 5%, 10%, and 15%, the resistance changes between wiring 6 and 7 are respectively 17.2%, 19.4%, and 21.6%, and the capacitance changes between wiring 6 and 8 are 7.5%, 15.3%, and 24.6%, which have remarkable resistance-capacitance dual-mode sensing characteristics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com