High-temperature superconductive magnetic suspension flywheel end cup-shaped suspension supporting component

A high-temperature superconducting and supporting component technology, applied in electrical components, electric components, casings/covers/supports, etc., can solve the problems of high friction and heat generation, short flywheel life, low energy storage density, etc., and achieve enhanced stability. , Stable and reliable suspension force, the effect of ensuring radial stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

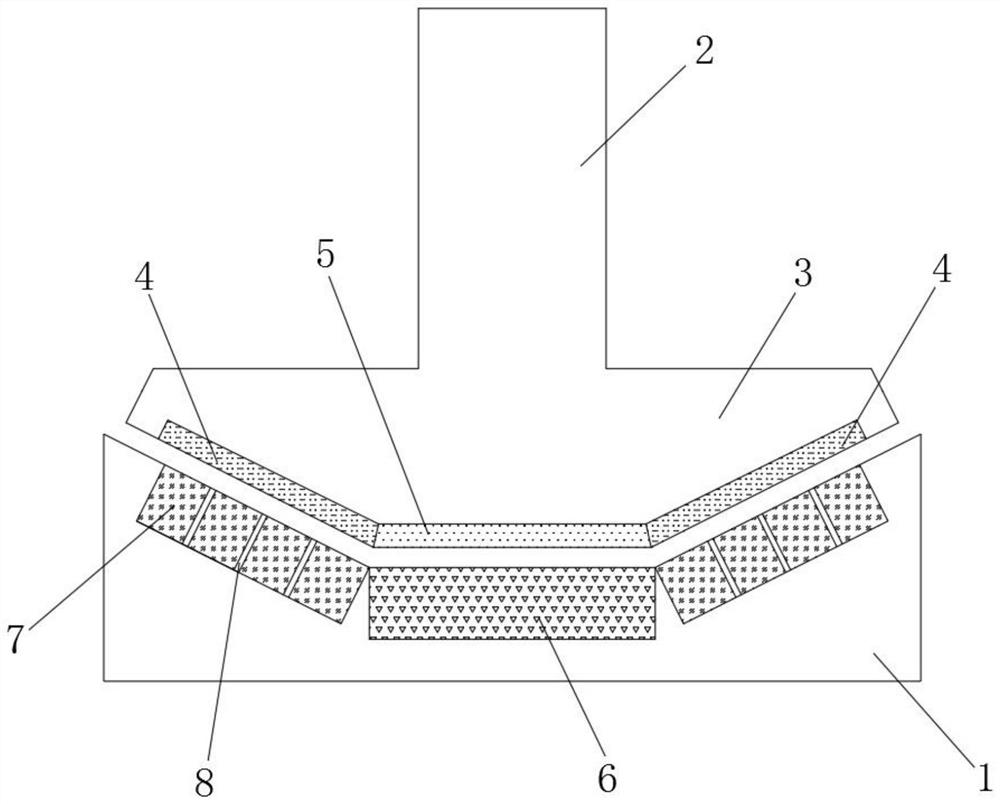

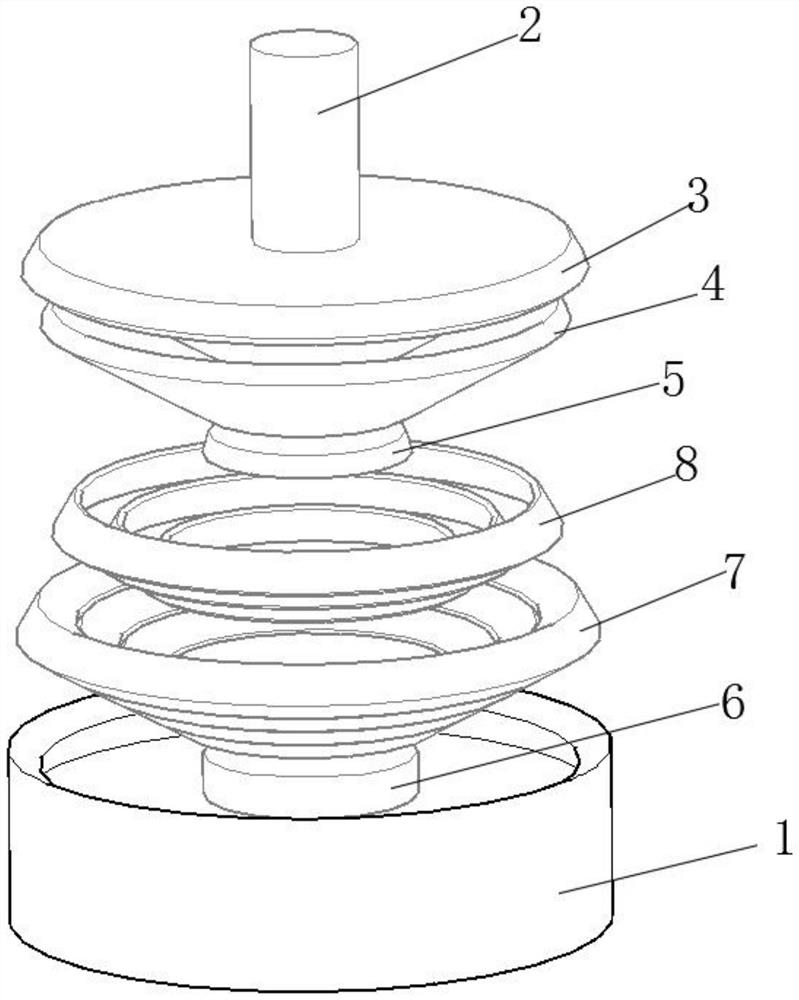

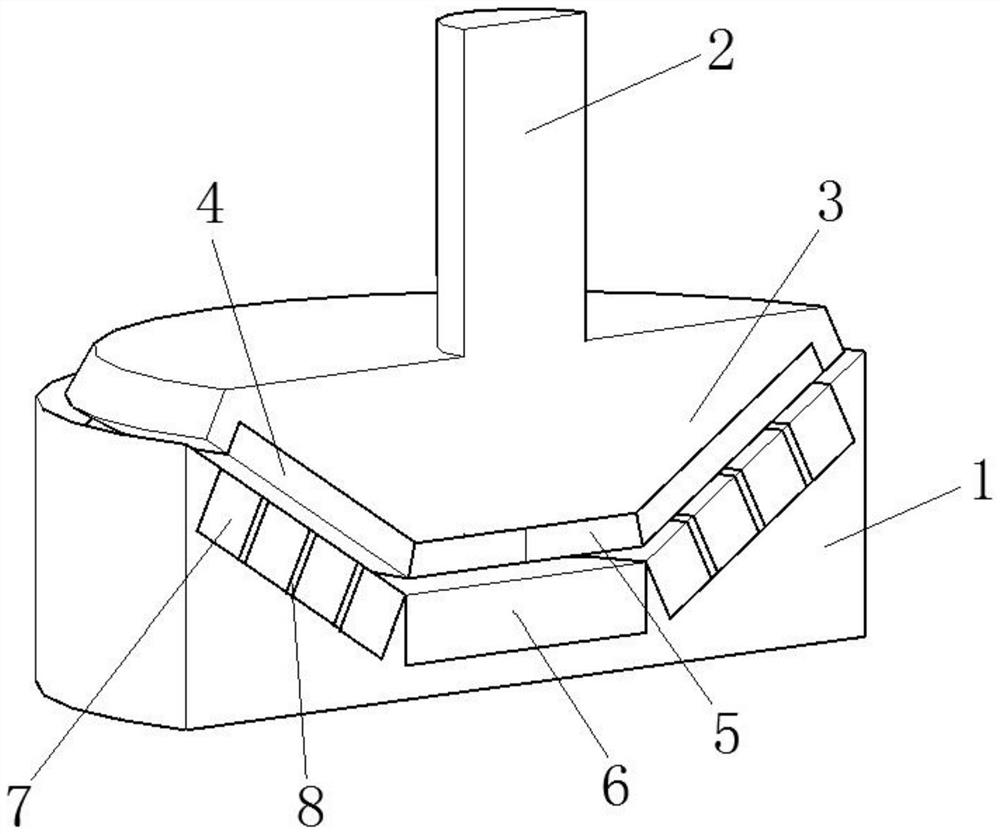

[0023] Such as Figure 1 to Figure 4 As shown, the present invention includes a base 1, an end shaft 2 and a shaft head 3. One end of the end shaft 2 is integrally formed with the shaft head 3. The lower part of the shaft head 3 is in the shape of a circular truncated cone. An inclined superconductor 4 is fixedly arranged on the inclined surface of the round table, a horizontal superconductor 5 is fixed on the bottom plane of the shaft head 3, a horizontal permanent magnet 6 and an inclined permanent magnet are fixedly installed in the base 1, and the inclined superconductor 4 is located on the inclined permanent magnet. Directly above the magnet, the horizontal superconductor 5 is located directly above the horizontal permanent magnet 6, the horizontal superconductor 5 and the horizontal permanent magnet 6 are all cylindrical, the horizontal superconductor 5, the horizontal permanent magnet 6, the end shaft 2 and the shaft Head 3 coax.

[0024] In this embodiment, the inclin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com