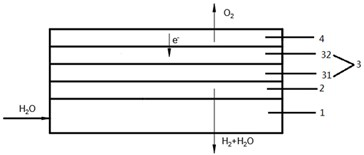

Solid oxide electrolytic cell with CGO/ESB double electrolyte layers

An electrolyte layer and electrolyte technology, applied in electrolytes, fuel cells, electrochemical generators, etc., can solve the problems of high operating costs and SOEC input voltage, and achieve the effect of saving operating costs and reducing input voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of CGO electrolyte powder by sol-gel combustion method: cerium nitrate hexahydrate (Ce(NO 3 ) 3 ·6H 2 O), gadolinium oxide (Gd 2 o 3 ) and citric acid (CA) as initial raw materials, each raw material was accurately weighed according to the stoichiometric ratio of CGO, and Gd was dissolved in dilute nitric acid 2 o 3 For powder, use deionized aqueous solution and other raw materials to form solutions respectively, then mix the above solutions, and use ammonia water to adjust the pH value of the mixed solution until the solution is neutral; the mixed solution is heated and stirred at 45°C for 10 hours to form a gel; the gel Heat in an electric furnace to form a light yellow powder; finally, keep the prepared powder at 600°C for 1h, then take it out and calcinate at 750°C for 2h to obtain CGO electrolyte powder.

[0037] ESB was synthesized by EDTA-citric acid sol-gel method (ie (Bi 2 o 3 ) 0.8 (Er 2 o 3 ) 0.2 ) Electrolyte powder: Accurately weigh a...

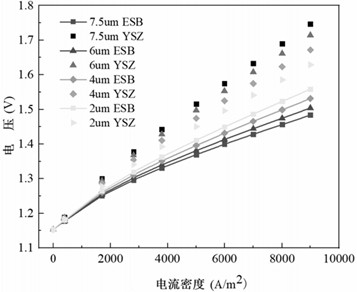

Embodiment 2

[0048] The CGO / YSZ electrolyte-based MS-SOEC was prepared by the same method as in Example 1, except that the thickness of the ESB electrolyte layer was 2 μm, and the thickness of the electrolyte functional layer was 12 μm.

Embodiment 3

[0050] The CGO / YSZ electrolyte-based MS-SOEC was prepared by the same method as in Example 1, except that the thickness of the ESB electrolyte layer was 4 μm, and the thickness of the electrolyte functional layer was 14 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com