Gallium nitride power device with grid high voltage resistance and low electric leakage

A power device, gallium nitride technology, applied in electrical components, semiconductor devices, circuits, etc., can solve the problems of low forward threshold voltage of devices, increased gate leakage, gate leakage, etc., to improve practicability and safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the present invention is described in detail:

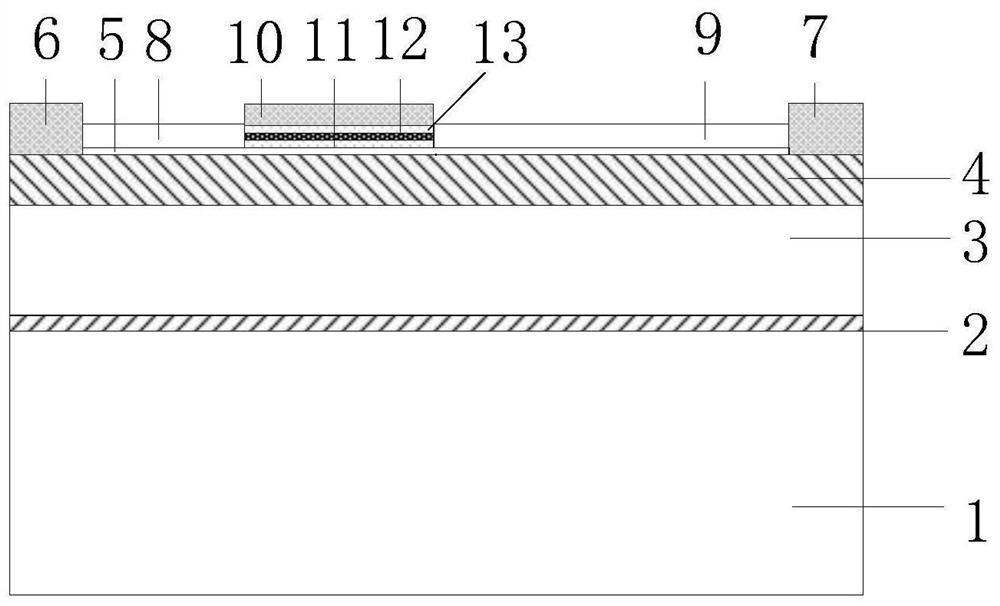

[0023] The gallium nitride power device with low gate leakage and high threshold voltage according to the present invention comprises: a P-type silicon substrate 1, an aluminum nitride buffer layer 2 is provided on the P-type silicon substrate 1, and the aluminum nitride buffer layer 2 is provided. An AlGaN buffer layer 3 is provided above the layer 2, a GaN buffer layer 4 is provided above the AlGaN buffer layer 3, and an AlGaN barrier layer 5 and source electrodes 6 at both ends are provided above the GaN buffer layer 4. and drain 7, there is metal above source 6 and drain 7 as source 6 and drain 7 respectively connecting both ends of AlGaN barrier layer 5 to the peripheral input / output, source 6 metal and AlGaN An ohmic contact is formed at the left end of the barrier layer 5 , an ohmic contact is formed between the drain 7 and the right end of the AlGaN barrier layer 5 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com