Rolling bearing fault diagnosis method based on CEEMDAN and GWO-NLM

A rolling bearing and fault diagnosis technology, which is applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., can solve the problems of distorted effective information, long decomposition time, large amount of calculation, etc., and achieve suppression of noise interference and suppression Effects of background noise and high computing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0049] This embodiment uses real experimental data for analysis, which is obtained from the Bearing Data Center of Western Reserve University. The faulty bearing selected for analysis is the 6205-2RJEM SKF deep groove ball bearing, and the faults of the inner and outer rings of the bearing are processed by single-site damage using EDM technology. The sampling frequency of vibration data is 12000HZ.

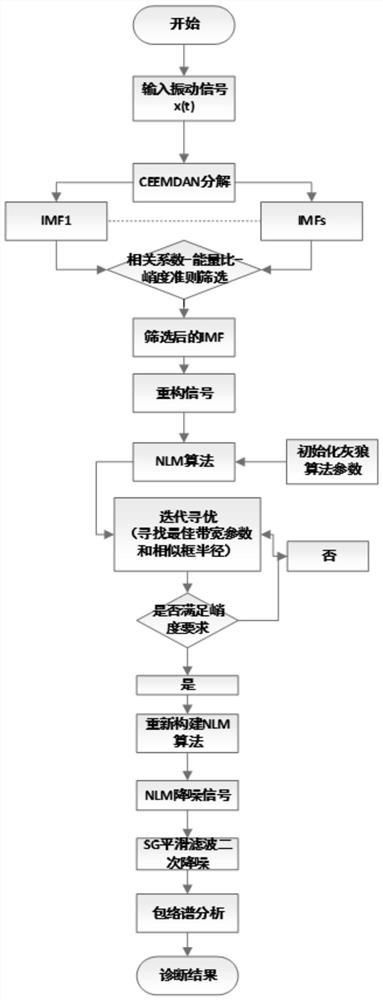

[0050] Such as figure 1 As shown, the rolling bearing fault diagnosis method based on CEEMDAN and GWO-NLM in this embodiment is as follows.

[0051] Step 1: Use the vibration sensor to collect the vibration signal of the rolling bearing, and measure the relevant parameters of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com