Polypropylene fiber bulked filament for environment-friendly fiber bundle filter and preparation method of polypropylene fiber bulked filament

The technology of bulked filament and fiber bundle is applied in the field of polypropylene bulked filament and its preparation, and can solve the problems of not considering the cross-sectional shape of the thick fiber filament, shortening the service life of the fiber filter, and blocking the use time of the fiber filter, etc. To achieve the effect of improving filtration efficiency and interception capacity, small filtration resistance and good rebound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A polypropylene bulked filament used for environmental protection fiber bundle filters, the linear density of the single filament is 40dtex, the linear density of the multifilament is 3000dtex, the addition ratio of fiber-grade polypropylene chips is 96.0%, and the addition ratio of anti-chlorine masterbatch is 2.0%, the addition ratio of anti-UV masterbatch is 2.0%.

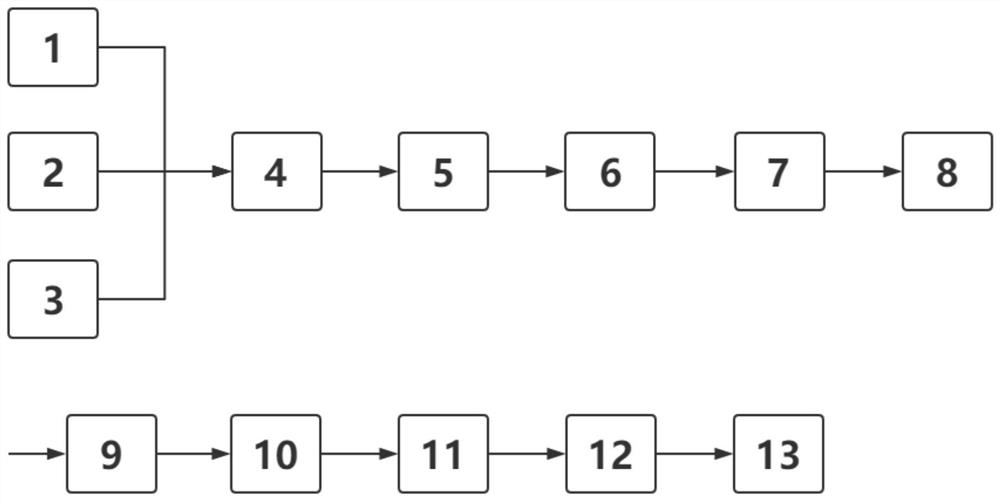

[0037] like figure 1 shown, including the following steps:

[0038] A: Add 1 polypropylene chip, 2 anti-chlorine masterbatch, and 3 anti-UV masterbatch in proportion, and put them into the extruder to melt after precise measurement of 4 raw and auxiliary materials. The temperature of each zone adopts a heating mode from high to low, five The heating temperatures were 210°C, 208°C, 206°C, 204°C and 202°C, respectively.

[0039] B: The molten fiber is spun through a 5-lobed special-shaped spinneret, and a three-lobed spinneret micro-hole is set on the 5-three-lobed special-shaped spinneret, and a three-lo...

Embodiment 2

[0047]A polypropylene bulked filament used for environmental protection fiber bundle filters, the linear density of the single filament is 43dtex, the linear density of the multifilament is 3300dtex, the addition ratio of fiber-grade polypropylene chips is 95.5%, and the addition ratio of anti-chlorine masterbatch is 2.0%, the anti-UV masterbatch addition ratio is 2.5%.

[0048] like figure 1 shown, including the following steps:

[0049] A: Add 1 polypropylene chip, 2 anti-chlorine masterbatch, and 3 anti-UV masterbatch in proportion, and put them into the extruder to melt after precise measurement of 4 raw and auxiliary materials. The temperature of each zone adopts a heating mode from high to low, five The heating temperatures were 215°C, 213°C, 210°C, 208°C and 206°C, respectively.

[0050] B: The molten fiber is spun through a 5-lobed special-shaped spinneret, and a three-lobed spinneret micro-hole is set on the 5-three-lobed special-shaped spinneret, and a three-lobed ...

Embodiment 3

[0058] A polypropylene bulked filament for environmental protection fiber bundle filter, the linear density of the single filament is 45dtex, the linear density of the multifilament is 3600dtex, the addition ratio of fiber-grade polypropylene chips is 95.0%, and the addition ratio of anti-chlorine masterbatch is 2.5%, the anti-UV masterbatch addition ratio is 2.5%.

[0059] like figure 1 shown, including the following steps:

[0060] A: Add 1 polypropylene chip, 2 anti-chlorine masterbatch, and 3 anti-UV masterbatch in proportion, and put them into the extruder to melt after precise measurement of 4 raw and auxiliary materials. The temperature of each zone adopts a heating mode from high to low, five The heating temperatures were 220°C, 218°C, 216°C, 214°C and 212°C, respectively.

[0061] B: The molten fiber is spun through a 5-lobed special-shaped spinneret, and a three-lobed spinneret micro-hole is set on the 5-three-lobed special-shaped spinneret, and a three-lobed speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com