Construction method of asphalt concrete and asphalt concrete pavement

A technology of asphalt concrete and construction method, which is applied to coagulation pavement paved on site, roads, roads, etc., can solve the problems of water stability reduction of asphalt concrete, and achieve the effects of improving water stability, promoting dispersion, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] An asphalt concrete comprises the following raw materials: 4.3kg of asphalt; 64.3kg of mineral material; 20kg of graphite powder; 0.21kg of polyester yarn; and 0.13kg of styrene-butadiene latex. Mineral grading is medium grain AC-16 type.

[0061] A construction method for asphalt concrete pavement, comprising the following steps:

[0062] S1. Preparation of asphalt concrete:

[0063] S11. Take each raw material of asphalt concrete according to the proportion, heat the mineral material to 185°C, add graphite powder and polyester filament to the heated mineral material for dry mixing, and the mixing time is 10s to obtain a dry mix.

[0064] S12. The styrene-butadiene latex is added to the asphalt and mixed evenly, and heated to 170° C., and then the dry mix is added to the heated asphalt for mixing, and the mixing time is 50s to obtain asphalt concrete.

[0065] S2. Clean up the garbage and vegetation on the roadbed, level the roadbed, then spread the asphalt concret...

Embodiment 2-5

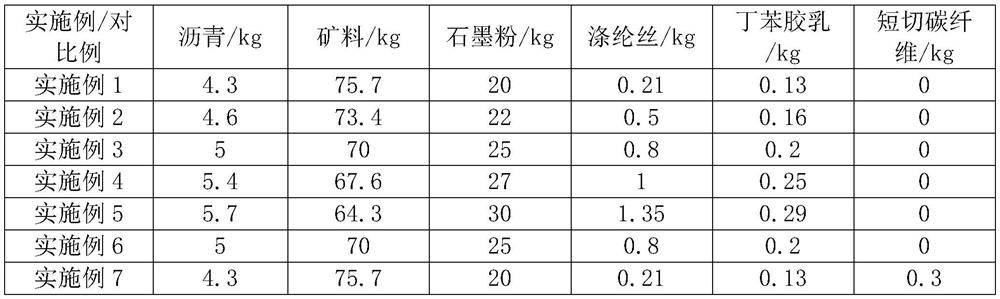

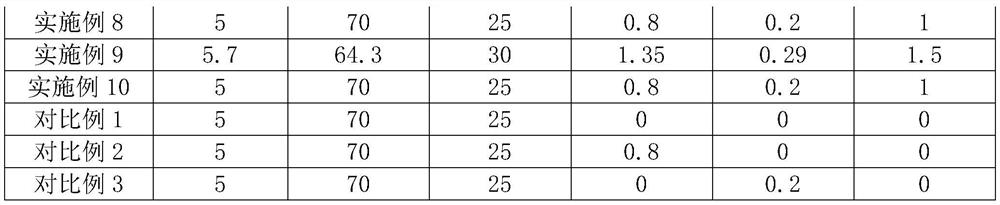

[0071] The difference between the following examples and Example 1 is: the consumption of each raw material is different, see Table 1 for details. The process parameters in the construction method are different, see Table 2 for details.

Embodiment 6

[0073] The difference between this embodiment and Embodiment 3 is that the mineral material gradation used in this embodiment is a fine-grained AC-10 type.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com