A kind of high foam-stabilizing, low-sensitivity concrete air-entraining agent and preparation method thereof

A low-sensitivity, concrete technology, applied in the field of low-sensitivity concrete air-entraining agent and preparation, high foam stability, can solve the problem of hard water in alpine areas, without considering the needs of air-entraining and foam stabilization, concrete air-entraining agent research Less problems, such as low CMC value, improved strength and viscoelasticity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

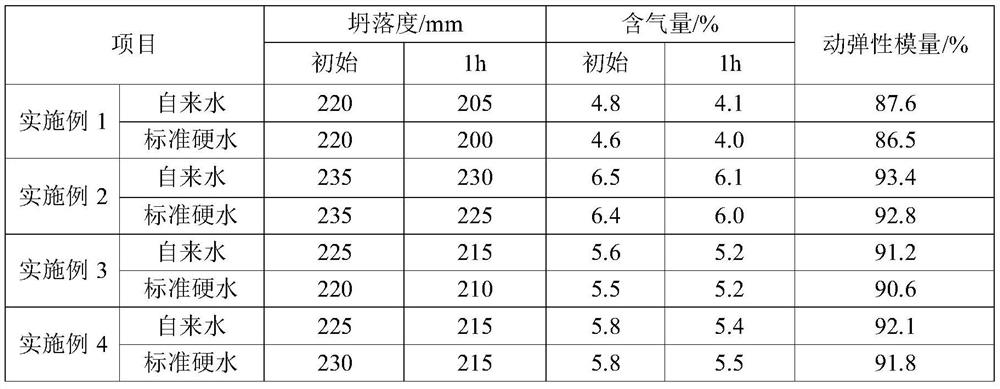

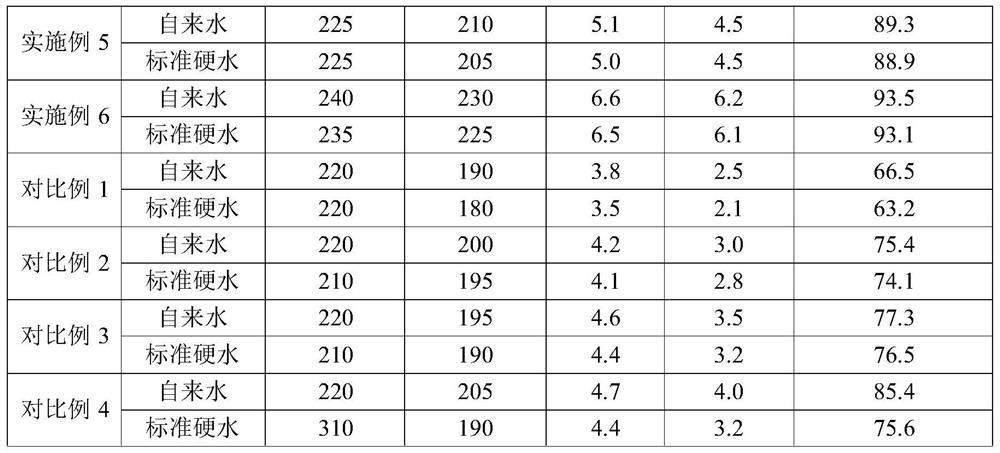

Examples

Embodiment 1

[0031] A high foam-stabilizing, low-sensitivity concrete air-entraining agent is prepared from the following components in terms of mass percentage: 20% of a gemini surfactant, 2% of a viscosity modifier, 2% of a foam stabilizer, and 1% of a synergist, water 75%;

[0032] The viscosity modifier is prepared from xanthan gum, guar gum and bone glue in a mass ratio of 1:0.2:1, and the synergist is sodium nitrite;

[0033] The preparation method of the high foam-stabilizing, low-sensitivity concrete air-entraining agent of the present embodiment is as follows:

[0034] Step 1: Preparation of Gemini Surfactant

[0035] (1) in the reactor, add the lauroyl chloride with dichloromethane as solvent, drip the pyridine of solution quality 1%, slowly add N,N-diethylethanolamine under ice bath and stirring condition, lauroyl chloride and N, The molar ratio of N-diethylethanolamine is 1:1.2, then the temperature is raised to 20°C, and the reaction is carried out for 3h to obtain the inter...

Embodiment 2

[0047] A highly foam-stabilizing, low-sensitivity concrete air-entraining agent is prepared from the following components in terms of mass percentage: 40% of a gemini surfactant, 3% of a viscosity modifier, 5% of a foam stabilizer, and 2% of a synergist, water 50%;

[0048] The viscosity modifier is prepared from xanthan gum, guar gum and bone glue in a mass ratio of 1:0.2:1.2, and the synergist is sodium nitrite;

[0049] The preparation method of the high foam-stabilizing, low-sensitivity concrete air-entraining agent of the present embodiment is as follows:

[0050] Step 1: Preparation of Gemini Surfactant

[0051] (1) in the reactor, add the lauroyl chloride with dichloromethane as solvent, drip the pyridine of solution quality 1%, slowly add N,N-diethylethanolamine under ice bath and stirring condition, lauroyl chloride and N, The molar ratio of N-diethylethanolamine is 1:1.4, then the temperature is raised to 25°C, and the reaction is carried out for 2h to obtain the int...

Embodiment 3

[0063] A highly foam-stabilizing, low-sensitivity concrete air-entraining agent is prepared from the following components in terms of mass percentage: 30% of a gemini surfactant, 3% of a viscosity modifier, 5% of a foam stabilizer, and 2% of a synergist, water 60%;

[0064] The viscosity modifier is prepared from xanthan gum, guar gum and bone glue in a mass ratio of 1:0.2:1.5, and the synergist is sodium nitrite;

[0065] The preparation method of the high foam-stabilizing, low-sensitivity concrete air-entraining agent of the present embodiment is as follows:

[0066] Step 1: Preparation of Gemini Surfactant

[0067] (1) in the reactor, add the lauroyl chloride with dichloromethane as solvent, drip the pyridine of solution quality 1.5%, slowly add N,N-diethylethanolamine under ice bath and stirring condition, lauroyl chloride and N, The molar ratio of N-diethylethanolamine is 1:1.2, then the temperature is raised to 25°C, and the reaction is carried out for 2h to obtain int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com