Machining method for PMI foam filling part

A processing method and foam filling technology, applied in the field of process heads, can solve the problems of milling broken parts, easy milling missing parts, parts deformation, etc., and achieve the effects of reducing part deformation, convenient clamping, and uniform surface allowance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

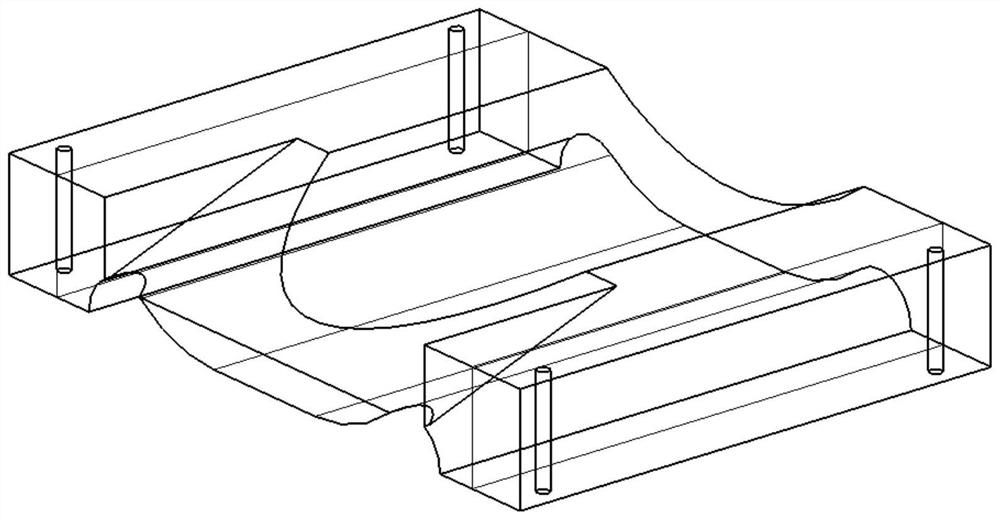

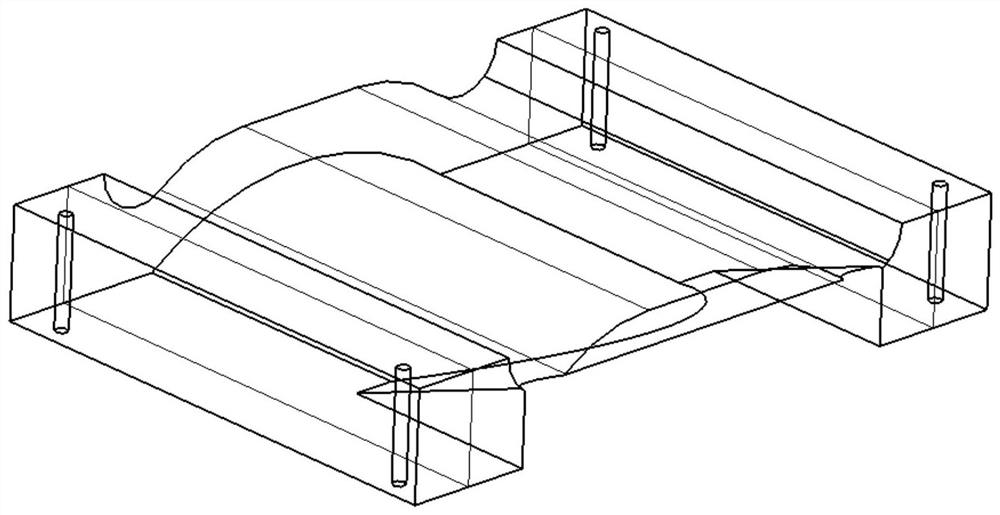

Image

Examples

Embodiment 1

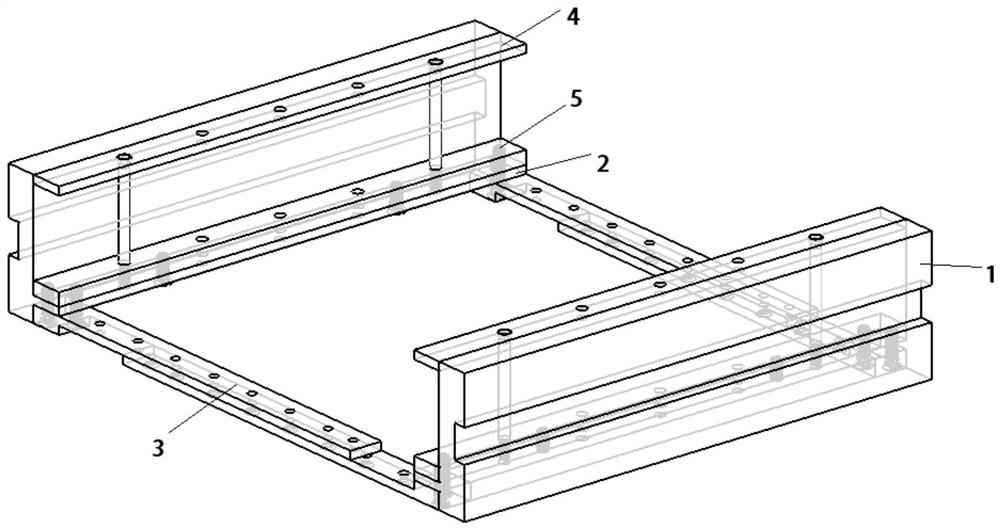

[0038] see Figure 3 to Figure 8 As shown, this embodiment provides a process head for processing PMI foam-filled parts, including two process head side stops 1 oppositely arranged. The process head side stop 1 is 300 mm long, 40 mm wide, and 80 mm high. A weight-reducing groove 7 is provided on the side surface of the process head side block 1 facing away, and a support plate 2 is provided on the opposite side surface of the process head side block 1. The distance between the bottom surface of the support plate 2 and the bottom surface of the process head side block 1 is 10 mm. 2 The distance between the top surface and the top surface of the process head is 65mm, and several screw holes are arranged on the support plate 2.

[0039] A length-adjustable connection assembly is arranged between the two process head side stops 1, and the connection assembly includes two stacked adjustment plates 3, the length of which is 250 mm, the width of 20 mm, and the height of 10 mm. One e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com