Cooling water channel embedded in hub mold and manufacturing method of cooling water channel

A technology of wheel hub mold and cooling water channel, which is applied in the direction of manufacturing tools, heat treatment equipment, casting molding equipment, etc., can solve the problems of reducing work efficiency, increasing repair cost, production stoppage, etc., to improve cooling effect, increase service life, and improve welding. The effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

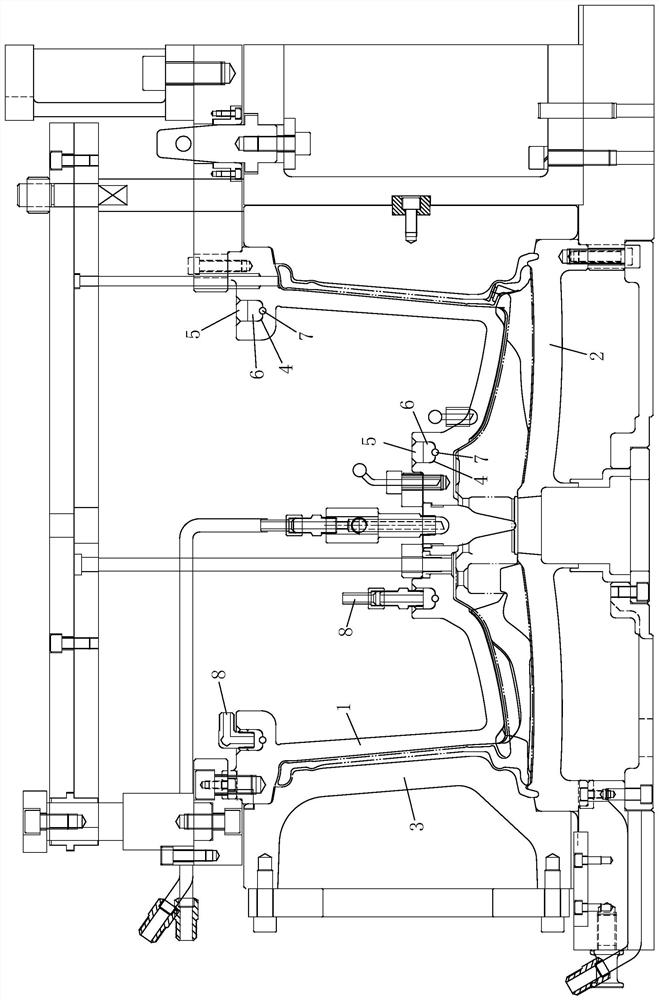

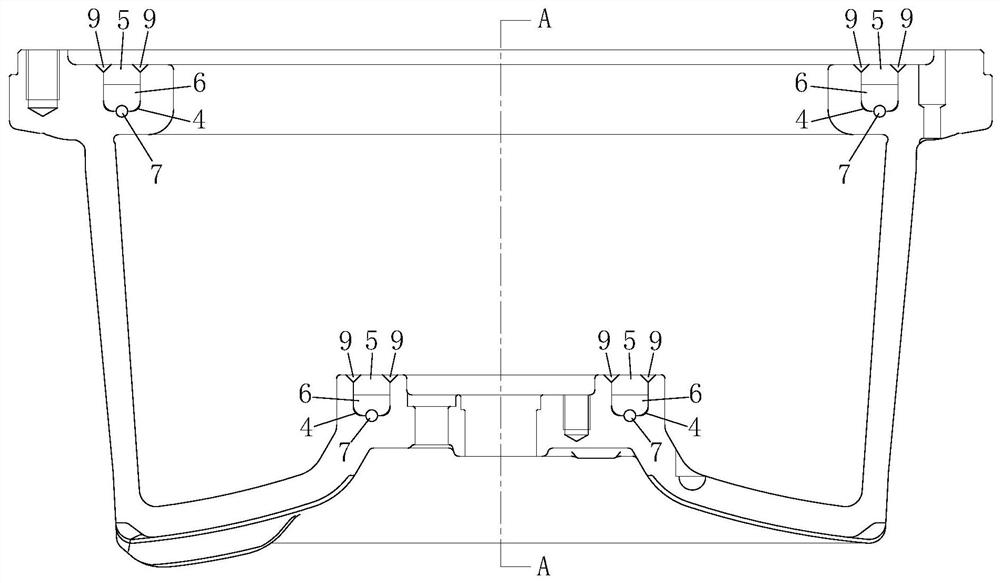

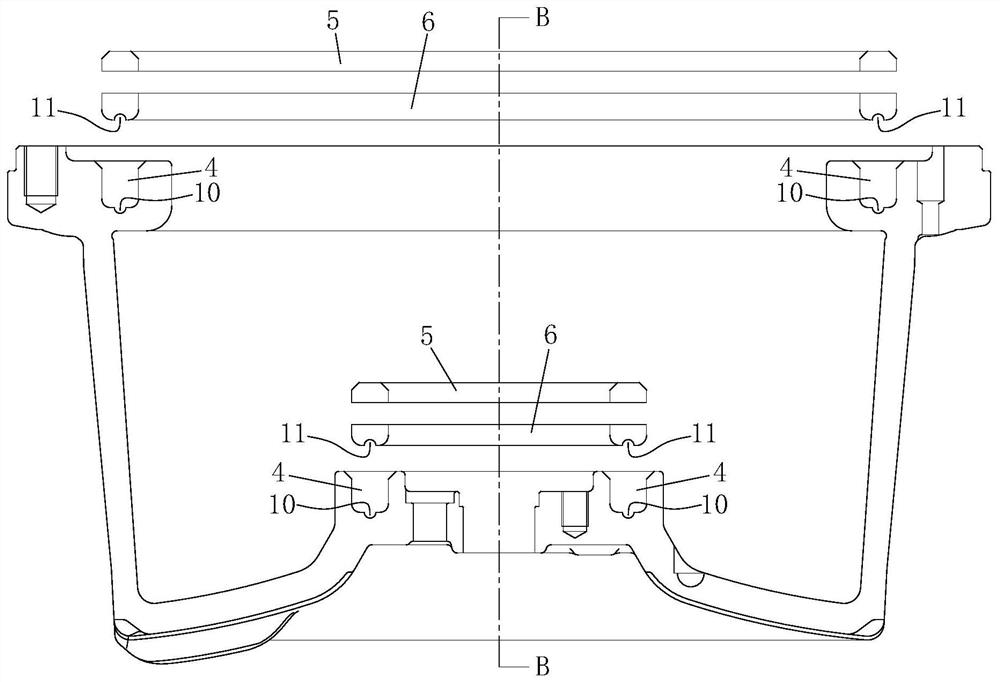

[0024] Example: see figure 1 , The wheel hub mold of the present invention includes an upper mold, a lower mold and a side mold, and the cooling water channel is buried in the mother body of the upper mold, the lower mold and the side mold. see Figure 2-Figure 9 , taking the upper mold as an example, the cooling water channel includes an annular groove arranged on the parent body, the bottom of the annular groove is provided with a semicircular lower groove, and an annular partition is embedded in the annular groove, and the bottom surface of the annular partition There is a semicircular upper groove, and the semicircular upper groove and the semicircular lower groove are relatively surrounded to form a cooling water channel. The annular partition is embedded with an annular cover plate, and the upper end of the annular cover plate and the annular groove flush, the inner and outer edges of the annular cover plate are respectively welded and fixed with the inner and outer edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com