Preparation method of palladium hydroxide carbon carrier catalyst

A technology of palladium hydroxide carbon and catalyst is applied in the field of preparation of palladium hydroxide carbon carrier catalyst, which can solve the problems of high production cost and high active component loading, and achieve the effects of increasing the number of applications, avoiding agglomeration and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

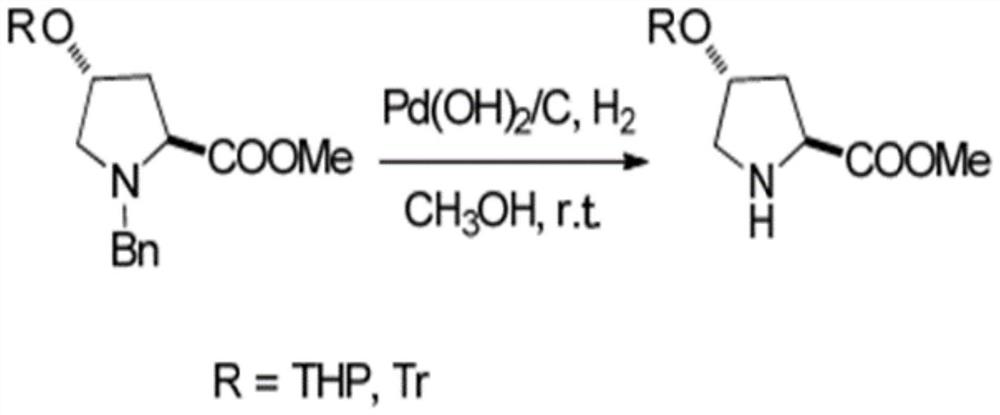

Image

Examples

preparation example Construction

[0021] A kind of preparation method of palladium hydroxide carbon carrier catalyst of the present invention, specifically implement according to the following steps:

[0022] Step 1, adding palladium acetate to acetone to form a palladium solution;

[0023] The concentration of palladium acetate in acetone is 100-200g / L;

[0024] Step 2, using palladium solution to soak the activated carbon, and performing ultrasonic treatment, then filtering and drying after standing still, to obtain surface-coated activated carbon;

[0025] The ultrasonic treatment time is 10-20min, the ultrasonic frequency is 40-70kHz, the ultrasonic treatment temperature is not higher than 30°C (used to discharge the air bubbles in the activated carbon); the standing time is 20-30min; the drying temperature is 60-80°C;

[0026] Step 3, adding high-substituted hydroxypropyl cellulose into the methanol solution to obtain the methanol solution, and then injecting the methanol solution into the pores of the c...

Embodiment 1

[0034] A kind of preparation method of palladium hydroxide carbon carrier catalyst of the present invention, specifically implement according to the following steps:

[0035] Step 1, adding palladium acetate to acetone to form a palladium solution;

[0036] The concentration of palladium acetate in acetone is 100g / L;

[0037] Step 2, using palladium solution to soak the activated carbon, and performing ultrasonic treatment, then filtering and drying after standing still, to obtain surface-coated activated carbon;

[0038] The ultrasonic treatment time is 10min, the ultrasonic frequency is 40kHz, the ultrasonic treatment temperature is not higher than 30°C; the standing time is 20min; the drying temperature is 60°C;

[0039] Step 3: Add high-substituted hydroxypropyl cellulose into the methanol solution to obtain methanol solution, then inject the methanol solution into the pores of the coated activated carbon by soaking and pouring, and dry at a constant temperature, and repe...

Embodiment 2

[0046] A kind of preparation method of palladium hydroxide carbon carrier catalyst of the present invention, specifically implement according to the following steps:

[0047] Step 1, adding palladium acetate to acetone to form a palladium solution;

[0048] The concentration of palladium acetate in acetone is 120g / L;

[0049] Step 2, using palladium solution to soak the activated carbon, and performing ultrasonic treatment, then filtering and drying after standing still, to obtain surface-coated activated carbon;

[0050] The ultrasonic treatment time is 15min, the ultrasonic frequency is 60kHz, the ultrasonic treatment temperature is not higher than 30°C; the standing time is 25min; the drying temperature is 70°C;

[0051] Step 3: Add high-substituted hydroxypropyl cellulose into the methanol solution to obtain methanol solution, then inject the methanol solution into the pores of the coated activated carbon by soaking and pouring, and dry at a constant temperature. clogged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com