Air bridge structure, manufacturing method of air bridge structure, superconducting quantum chip and manufacturing method of superconducting quantum chip

A fabrication method and air bridge technology, which are applied in the manufacturing of quantum computers, superconducting devices, semiconductor/solid-state devices, etc., to prevent etching damage and improve performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

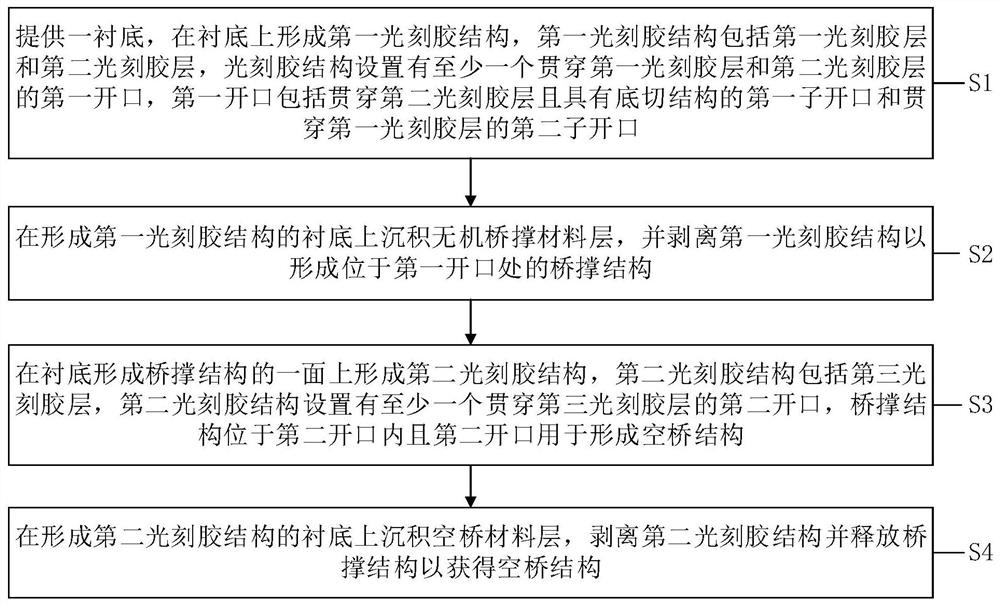

[0102] For ease of understanding, the present embodiment provides a method of manufacturing air bridge structure 501 in particular embodiments, the particular embodiment comprises the steps of:

[0103] Step 1: formation of a first resist structure 2 on the substrate 1.

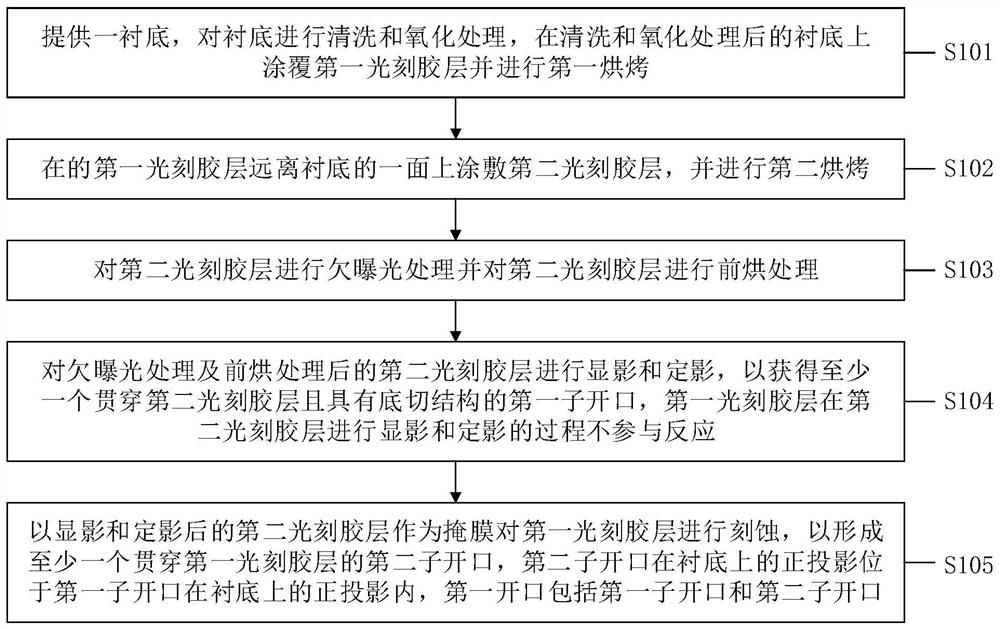

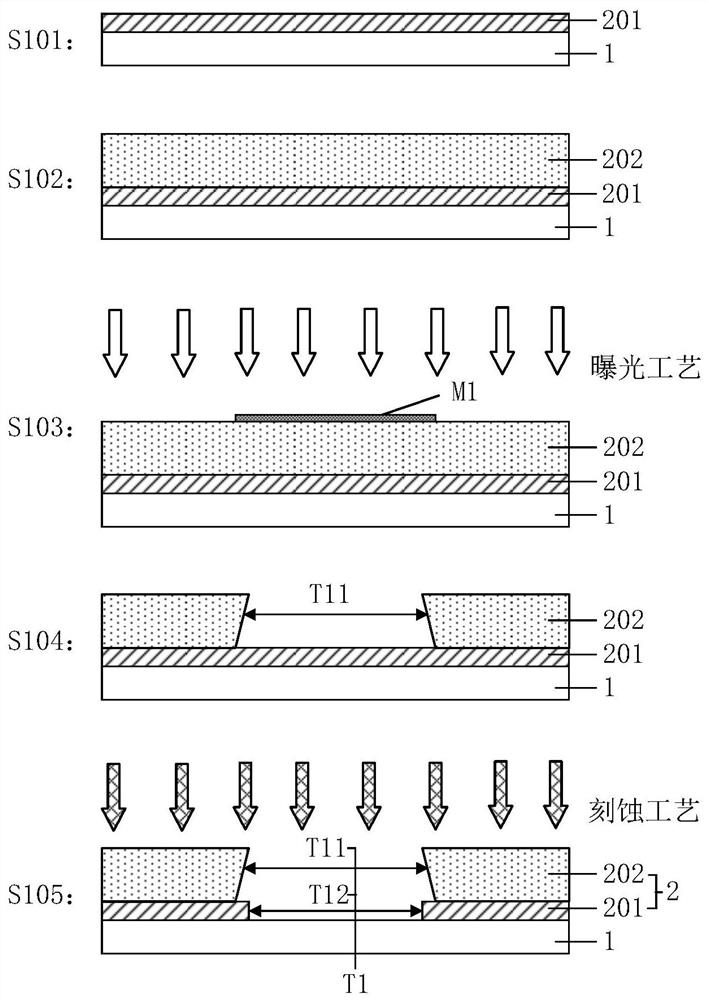

[0104] On a substrate after cleaning and oxidation process through a spin-coating PMMA (polymethyl methacrylate, acrylic) gum as a first photoresist layer 201 and baked at 180 [deg.] C 100s ~ 150s;

[0105] A first photoresist layer 201 on the AZ series inverted spin-coated photoresist layer 202 as a second gum, and baked at 95 deg.] C 60s ~ 120s;

[0106] UV exposure method to pre-bake treatment for 95 deg.] C, then exposed using a mask 45s ~ 90s, the exposure time is less than the second thickness of the photoresist layer 202 at a sufficient exposure time, i.e. for underexposure process;

[0107] After the substrate 1 was placed under the exposure process of a 2.38% TMAH developer, development time of 30s ~ 45s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com