Experimental device and method for measuring the heat transfer limit of a stepped metal heat pipe liquid-absorbing core

A metal heat pipe and experimental device technology, applied in the direction of material heat development, material thermal conductivity, greenhouse gas reduction, etc., can solve the problems of heat transfer performance deterioration of heat pipes, liquid can not flow back, etc., to prevent heat transfer limit, reduce heat loss, The effect of improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Now in conjunction with example and accompanying drawing, the present invention will be further described:

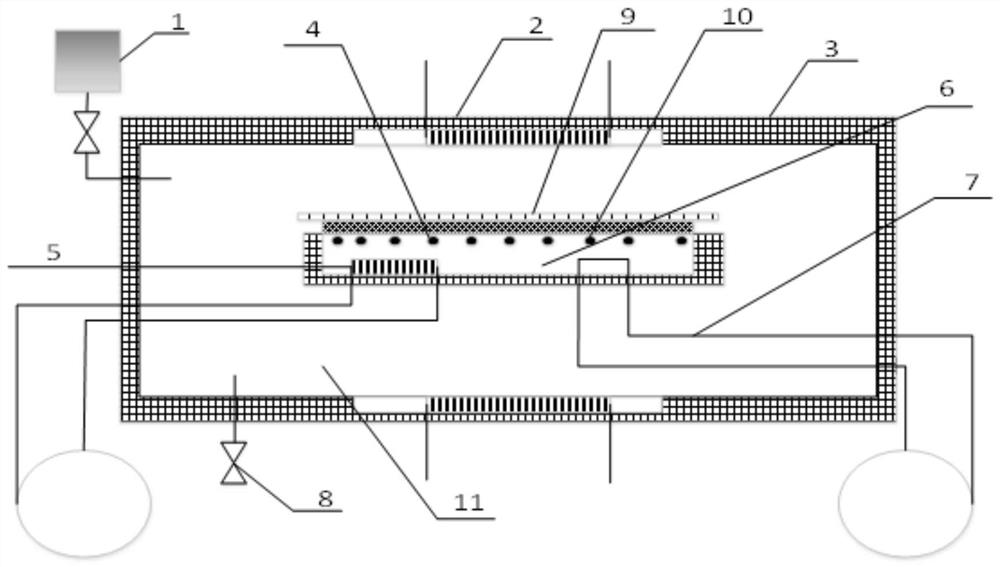

[0017] like figure 1 As shown in the figure, this embodiment is an experimental device for measuring the heat transfer limit of a stepped metal heat pipe liquid wick, including a pressure sensor 1, a protective heater 2, a containment shell 3, a thermocouple 4, an evaporator 5, and a copper core mounting plate 6 , condenser 7, liquid level controller 8, stainless steel pressure plate 9, absorbent core 10, polyester / cotton material 11; the thermocouple 4, evaporator 5, copper core mounting plate 6, condenser 7, liquid level controller 8. The stainless steel pressure plate 9 and the liquid absorbing core 10 form a test loop; the copper core mounting plate 6 is evenly divided into three parts along the axial direction, from left to right are the evaporation end, the adiabatic end, and the condensation end; the pressure sensor 1 The pressure detection is realized by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com