Preparation method of environment-friendly modified sesame albumen glue mucilage

A protein glue and modification technology, which is applied in the field of plant protein modification, can solve the problems of speed up, anti-corrosion performance improvement, reduction of adhesive water resistance and bonding strength, etc., to improve bonding strength and water resistance, and enhance dryness. Strength and wet strength, the effect of maintaining natural properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

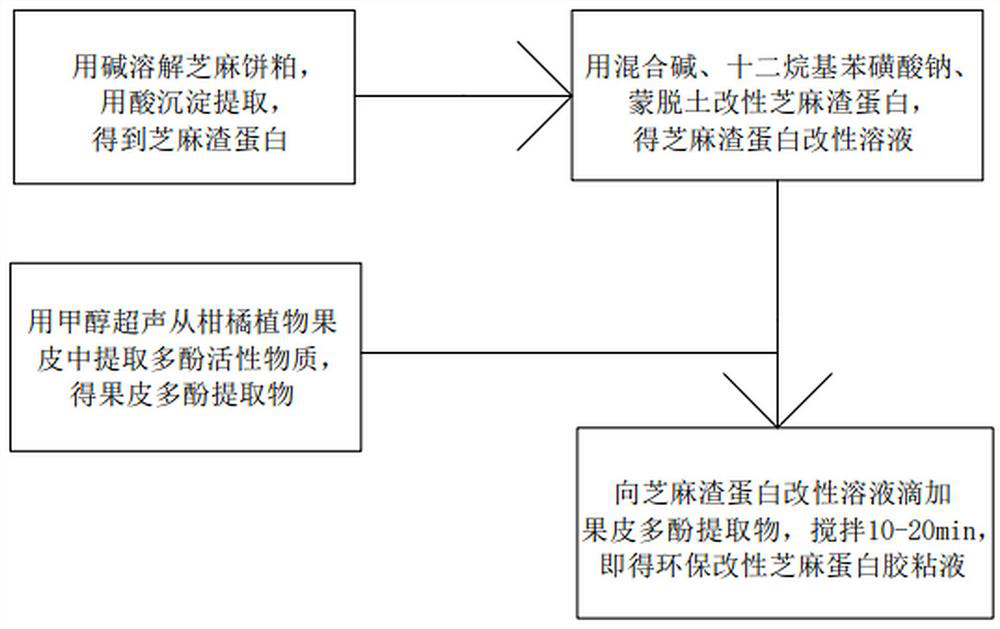

Method used

Image

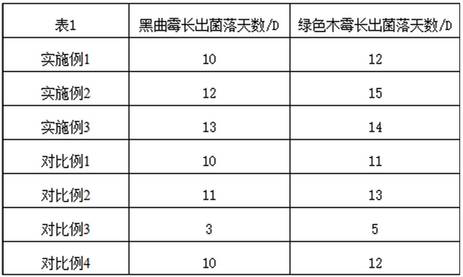

Examples

Embodiment 1

[0025] A kind of preparation method of environment-friendly modified sesame protein glue, is prepared by the following steps:

[0026] (1) Mix 100g of sesame cake meal with 2L of distilled water, adjust the pH value to 9 with sodium hydroxide solution at 45°C, stir for 2.5 hours, centrifuge, take the supernatant, then adjust the pH value to 4.0 with hydrochloric acid solution, and stir 5min, refrigerated at 4°C for 20min, centrifuged, the obtained precipitate was washed twice with distilled water, centrifuged, then adjusted to neutrality with sodium hydroxide solution, freeze-dried, finally pulverized with a ball mill, passed through a 100-mesh sieve, and obtained sesame residue protein. spare;

[0027] (2) Mince 10 g of fresh citrus peel, add it to 300 mL of methanol, conduct ultrasonic extraction at 50° C. for 25 minutes, cool to room temperature, filter to obtain a filtrate, then concentrate the filtrate to obtain a peel polyphenol extract, and set aside;

[0028] (3) Mix ...

Embodiment 2

[0033] A kind of preparation method of environment-friendly modified sesame protein glue, is prepared by the following steps:

[0034](1) Mix 110g of sesame cake meal with 2.2L of distilled water, adjust the pH value to 10 with sodium hydroxide solution at 50°C, stir for 3.0 hours, centrifuge, take the supernatant, and then adjust the pH value to 4.2 with hydrochloric acid solution, Stir for 8 minutes, refrigerate at 5°C for 25 minutes, centrifuge, wash the obtained precipitate twice with distilled water, centrifuge, adjust to neutrality with sodium hydroxide solution, freeze-dry, and finally crush with a ball mill, pass through a 100-mesh sieve to obtain sesame residue protein ,spare;

[0035] (2) Mince 15 g of fresh citrus fruit peel, then add it to 350 mL of methanol, conduct ultrasonic extraction at 55° C. for 30 minutes, cool to room temperature, filter to obtain a filtrate, then concentrate the filtrate to obtain a peel polyphenol extract, and set aside;

[0036] (3) Mi...

Embodiment 3

[0041] A kind of preparation method of environment-friendly modified sesame protein glue, is prepared by the following steps:

[0042] (1) Mix 120g of sesame cake meal with 2.5L of distilled water, adjust the pH value to 11 with sodium hydroxide solution at 55°C, stir for 3.5 hours, centrifuge, take the supernatant, and then adjust the pH value to 4.5 with hydrochloric acid solution, Stir for 10 minutes, refrigerate at 6°C for 30 minutes, centrifuge, wash the obtained precipitate twice with distilled water, centrifuge, adjust to neutrality with sodium hydroxide solution, freeze-dry, finally crush with a ball mill, and pass through a 100-mesh sieve to obtain sesame residue protein ,spare;

[0043] (2) Mince 20 g of fresh citrus peel, add it to 400 mL of methanol, conduct ultrasonic extraction at 60° C. for 35 minutes, cool to room temperature, filter to obtain the filtrate, then concentrate the filtrate to obtain the polyphenol extract of the peel, and set aside;

[0044] (3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com