Multi-resin composite material and preparation method thereof

A resin composite material and liquid material technology, applied in the field of polymer building materials, can solve the problems of complex production process, poor mechanical performance and high production cost of functional exterior wall decoration materials, and achieve the purpose of strengthening the overall space connection strength and production energy consumption Low, comprehensive use cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

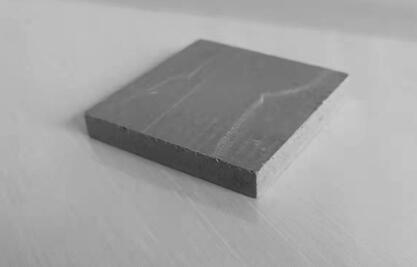

Image

Examples

Embodiment 1

[0061] The preparation method of multi-resin composite material of the present invention comprises the steps:

[0062] Step 1. Prepare inorganic powder components according to the ratio of parts by weight, and divide the inorganic powder components into a first inorganic powder component and a second inorganic powder component, and mix them uniformly;

[0063] Among them, the inorganic powder components, in terms of weight fractions, include 30 parts of mineral powder, 8 parts of fly ash, 4 parts of pozzolan, 4 parts of mica powder, 10 parts of calcium carbonate, 7 parts of aluminum hydroxide, and 7 parts of magnesium hydroxide , 5 parts of expanded graphite and 5 parts of ammonium zinc phosphate; the first inorganic powder component is 30 parts of mineral powder, 4 parts of mica powder, 10 parts of calcium carbonate; the second inorganic powder component is 10 parts of fly ash, volcanic ash 4 parts, aluminum hydroxide 7 parts, magnesium hydroxide 7 parts, expanded graphite 5 ...

Embodiment 2

[0069] The preparation method of multi-resin composite material of the present invention comprises the steps:

[0070] Step 1. Prepare inorganic powder components according to the ratio of parts by weight, and divide the inorganic powder components into a first inorganic powder component and a second inorganic powder component, and mix them uniformly;

[0071] Among them, the inorganic powder components, in terms of weight fractions, include 50 parts of mineral powder, 12 parts of fly ash, 8 parts of pozzolan, 8 parts of mica powder, 15 parts of calcium carbonate, 10 parts of aluminum hydroxide, and 10 parts of magnesium hydroxide , 10 parts of expanded graphite and 10 parts of ammonium zinc phosphate; the first inorganic powder component is 50 parts of mineral powder, 8 parts of mica powder, and 15 parts of calcium carbonate; the second inorganic powder component is 15 parts of fly ash, volcanic ash 8 parts, aluminum hydroxide 10 parts, magnesium hydroxide 10 parts, expanded ...

Embodiment 3

[0077] The preparation method of multi-resin composite material of the present invention comprises the steps:

[0078] Step 1. Prepare inorganic powder components according to the ratio of parts by weight, and divide the inorganic powder components into a first inorganic powder component and a second inorganic powder component, and mix them uniformly;

[0079] Among them, the inorganic powder components, in terms of weight fractions, include 40 parts of mineral powder, 12 parts of fly ash, 6 parts of volcanic ash, 6 parts of mica powder, 12 parts of calcium carbonate, 9 parts of aluminum hydroxide, and 9 parts of magnesium hydroxide , 7 parts of expanded graphite and 7 parts of ammonium zinc phosphate; the first inorganic powder component is 40 parts of mineral powder, 6 parts of mica powder, and 12 parts of calcium carbonate; the second inorganic powder component is 12 parts of fly ash, volcanic ash 6 parts, 9 parts of aluminum hydroxide, 9 parts of magnesium hydroxide, 7 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com