Degradable material and preparation method thereof

A degradable material and modification technology, applied in the field of composite materials, can solve the problems of difficult reduction, white pollution, poor natural degradability, etc., and achieve the effect of improving strength and increasing service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

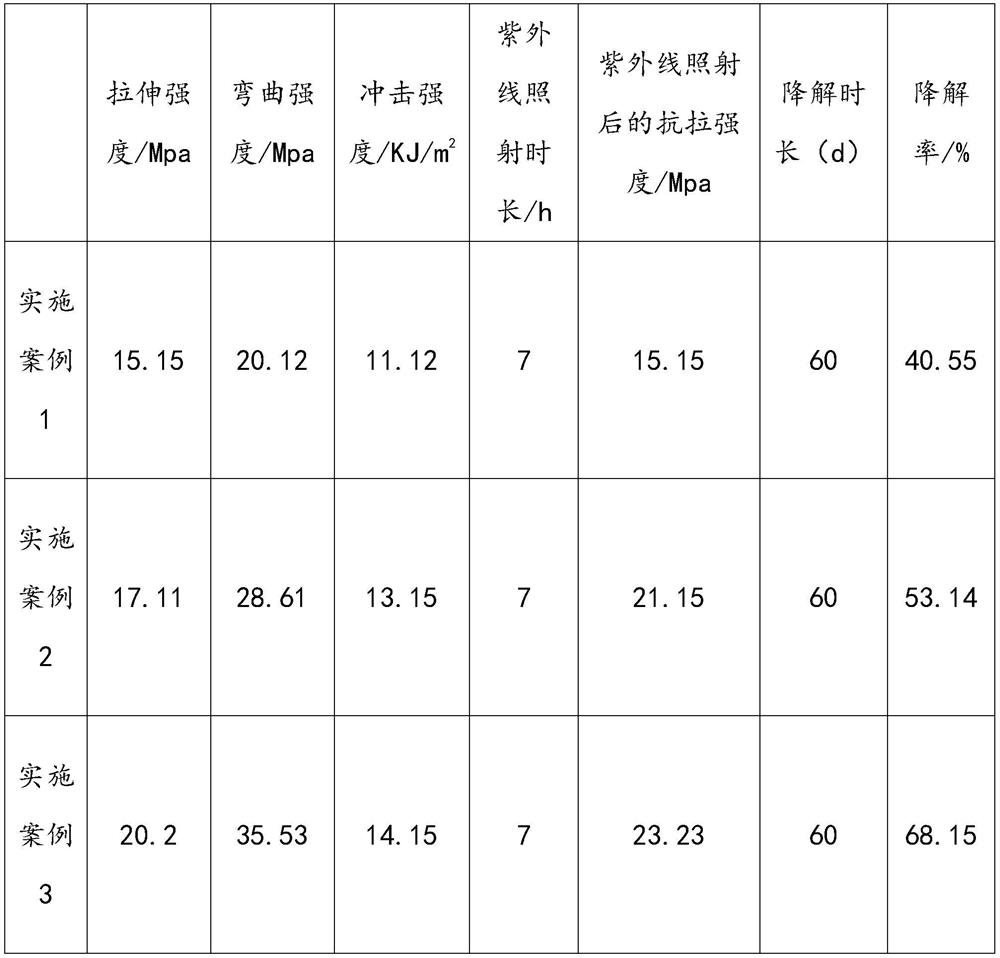

Embodiment example 1

[0051] Weigh 90 parts of microcrystalline starch, 80 parts of sodium hydroxide solution, 50 parts of triruthenium dodecacarbonyl, 60 parts of depolyhydroxybutyrate, 45 parts of chitosan and 20 parts of silane coupling agent, send the microcrystalline starch to Put it into the mixing tank, feed carbon dioxide and fumigate for 20 minutes, then add the fumigated microcrystalline starch into the ultrasonic emulsification disperser, add sodium hydroxide solution, and carry out ultrasonic dispersion treatment. After treatment, the ultrasonic dispersion treatment mixed solution is obtained. Sieve the ultrasonic dispersion treatment mixed solution to remove large particle precipitation, put triruthenium dodecacarbonyl and polyhydroxybutyrate into the sieved ultrasonic dispersion treatment mixed solution, put it into a magnetic stirrer, stir magnetically for 20 minutes, and pump Filter, dry the product after suction filtration at 135°C for 3h, send it into a muffle furnace, calcinate at...

Embodiment example 2

[0057] Weigh 90 parts of microcrystalline starch, 80 parts of sodium hydroxide solution, 50 parts of triruthenium dodecacarbonyl, 60 parts of depolyhydroxybutyrate, 45 parts of chitosan and 20 parts of silane coupling agent, send the microcrystalline starch to Put it into the mixing tank, feed carbon dioxide and fumigate for 20 minutes, then add the fumigated microcrystalline starch into the ultrasonic emulsification disperser, add sodium hydroxide solution, and carry out ultrasonic dispersion treatment. After treatment, the ultrasonic dispersion treatment mixed solution is obtained. Sieve the ultrasonic dispersion treatment mixed solution to remove large particle precipitation, put triruthenium dodecacarbonyl and polyhydroxybutyrate into the sieved ultrasonic dispersion treatment mixed solution, put it into a magnetic stirrer, stir magnetically for 20 minutes, and pump Filter, dry the product after suction filtration at 135°C for 3h, send it into a muffle furnace, calcinate at...

Embodiment example 3

[0063] Weigh 90 parts of microcrystalline starch, 80 parts of sodium hydroxide solution, 50 parts of triruthenium dodecacarbonyl, 60 parts of depolyhydroxybutyrate, 45 parts of chitosan and 20 parts of silane coupling agent, send the microcrystalline starch to Put it into the mixing tank, feed carbon dioxide and fumigate for 20 minutes, then add the fumigated microcrystalline starch into the ultrasonic emulsification disperser, add sodium hydroxide solution, and carry out ultrasonic dispersion treatment. After treatment, the ultrasonic dispersion treatment mixed solution is obtained. Sieve the ultrasonic dispersion treatment mixed solution to remove large particle precipitation, put triruthenium dodecacarbonyl and polyhydroxybutyrate into the sieved ultrasonic dispersion treatment mixed solution, put it into a magnetic stirrer, stir magnetically for 20 minutes, and pump Filter, dry the product after suction filtration at 135°C for 3h, send it into a muffle furnace, calcinate at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com