Modified ardealite stabilized macadam as well as preparation method and application thereof

A technology for stabilizing crushed stone and phosphogypsum, used in climate sustainability, sustainable waste treatment, solid waste management, etc., to solve problems such as poor shrinkage, load cracks, and reduced service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

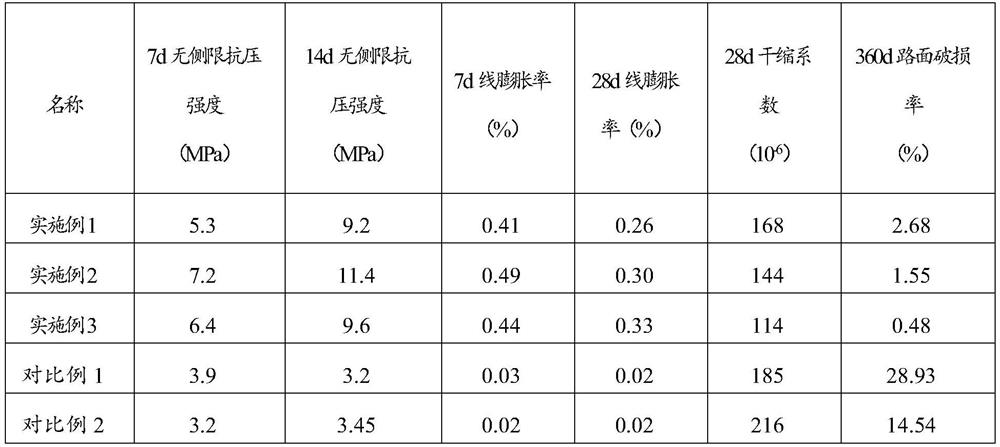

Examples

preparation example Construction

[0028] In the present invention, the preparation method of the modified phosphogypsum preferably includes the following steps: mixing the original phosphogypsum, mineral powder and an alkaline activator, and then aging to obtain the modified phosphogypsum. In the present invention, the aging time is preferably 3-45 days. In the present invention, when the temperature is ≥30°C, the aging time is preferably 3d; when the temperature is ≥15°C and <30°C, the aging time is preferably 7d; when the temperature is ≥0°C and <15°C , the aging time is preferably 12d; when the temperature is <0°C, the aging time is preferably 22d-45d.

[0029] In the present invention, the C-S-H gel formed in the aging process is represented by CaSO in phosphogypsum 4Gradually grow the crystal nuclei and wrap them, so that the air-hardening phosphogypsum becomes a hydraulic material. On the one hand, some fine-grained phosphogypsum is cemented into larger granular, blocky, and strong Large particles of p...

Embodiment 1

[0042] A modified phosphogypsum stabilized crushed stone, the composition of the raw materials is as follows in parts by mass: 800 parts of modified phosphogypsum, 65 parts of mineral powder, 1 part of red mud, 9 parts of cement, 1290 parts of crushed stone, 60 parts of chemical fiber, 100 parts of water.

[0043] Among them, the raw materials of the modified phosphogypsum include the following mass fractions: 95% of the original phosphogypsum, the original phosphogypsum is the phosphogypsum that has been stored for more than 3 years, the moisture content is 18.6%, the CaSO 4 The content is 87%, the water-soluble phosphorus content is 0.5%, the water-soluble fluorine content is 0.09%, and the pH value is 3.2; 1% mineral powder, the mineral powder is S95 grade granulated blast furnace slag powder, Al 2 o 3 The content is 11%, the activity index is 99%; 4% of the basic activator, the basic activator is composed of the following raw materials in mass fractions: 84% of P·O 32.5 o...

Embodiment 2

[0052] A modified phosphogypsum stabilized crushed stone. The raw material composition is as follows in parts by mass: 850 parts of modified phosphogypsum, 107 parts of mineral powder, 5 parts of red mud, 15 parts of cement, 1170 parts of crushed stone, 90 parts of chemical fiber, 140 parts of water.

[0053] Among them, the raw materials of the modified phosphogypsum include the following raw materials in mass fraction: 88% of the original phosphogypsum, the original phosphogypsum is the phosphogypsum that has been stockpiled for more than 3 years, the moisture content is 15.2%, the CaSO 4 The content is 86%, the content of water-soluble phosphorus is 0.46%, the content of water-soluble fluorine is 0.1%, and the pH value is 3.1; the mineral powder is 6.4%, and the mineral powder is S95 grade granulated blast furnace slag powder, Al 2 o 3 The content is 11%, the activity index is 99%; 5.6% of the basic activator, the basic activator is P·O 42.5 ordinary portland cement.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com