Conductive mineral material and preparation method thereof and mineralized filter element with conductive mineral material

A technology of mineralization filter element and minerals, applied in conductive materials dispersed in non-conductive inorganic materials, chemical instruments and methods, electrochemical water/sewage treatment, etc., can solve the problem of slow release rate of trace elements and achieve enhanced The effect of release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

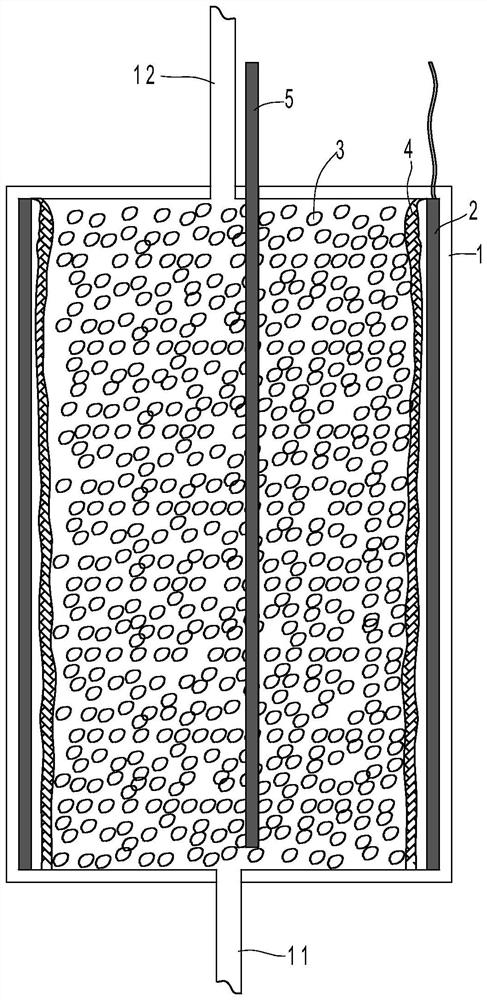

[0033] The preparation of the mineralized filter element with electrical conductivity is mainly divided into 3 steps:

[0034] In the first step, crush medical stone, olivine, pearl oyster, and tourmaline to 200 mesh respectively, take 45 parts of medical stone, 20 parts of olivine, 25 parts of pearl oyster, and 10 parts of tourmaline, and use The mixer mixes the raw stone powder.

[0035] In the second step, take 66 parts of mixed raw stone powder and 4 parts of conductive carbon black and mix them with a mixer, take 10 parts of PVDF and add them to 20 parts of DMF to stir and dissolve to prepare a polymer solution, and then mix the raw stone The powder, conductive carbon black and polymer solution are mixed with a mixer to prepare a slurry. The slurry is granulated by an extruder to prepare a granular billet with a diameter of 2-2.5 mm. Then put the blank material into a drying oven for drying to prepare a shaped conductive mineral material.

[0036] In the third step, th...

Embodiment 2

[0040] Embodiment 2: The preparation of the mineralized filter element with electrical conductivity is mainly divided into 3 steps:

[0041] In the first step, the original stones of medical stone, olivine, wood fish stone and limestone are crushed to 300 mesh respectively, and 50 parts of medical stone, 20 parts of olivine, 20 parts of wood fish stone and 10 parts of limestone are taken respectively, and used The mixer mixes the raw stone powder.

[0042] In the second step, take 68 parts of mixed raw stone powder and 2 parts of carbon fiber and mix them with a mixer, take 10 parts of PVDF and add them to 20 parts of DMAC to stir and dissolve to prepare a polymer solution, and then mix the mixed raw stone powder , carbon fiber and polymer solution are mixed with a mixer to prepare a slurry. The slurry is granulated by an extruder to prepare a granular billet with a diameter of 2.5-3 mm. Then put the blank material into a drying oven for drying to prepare a shaped conductive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com