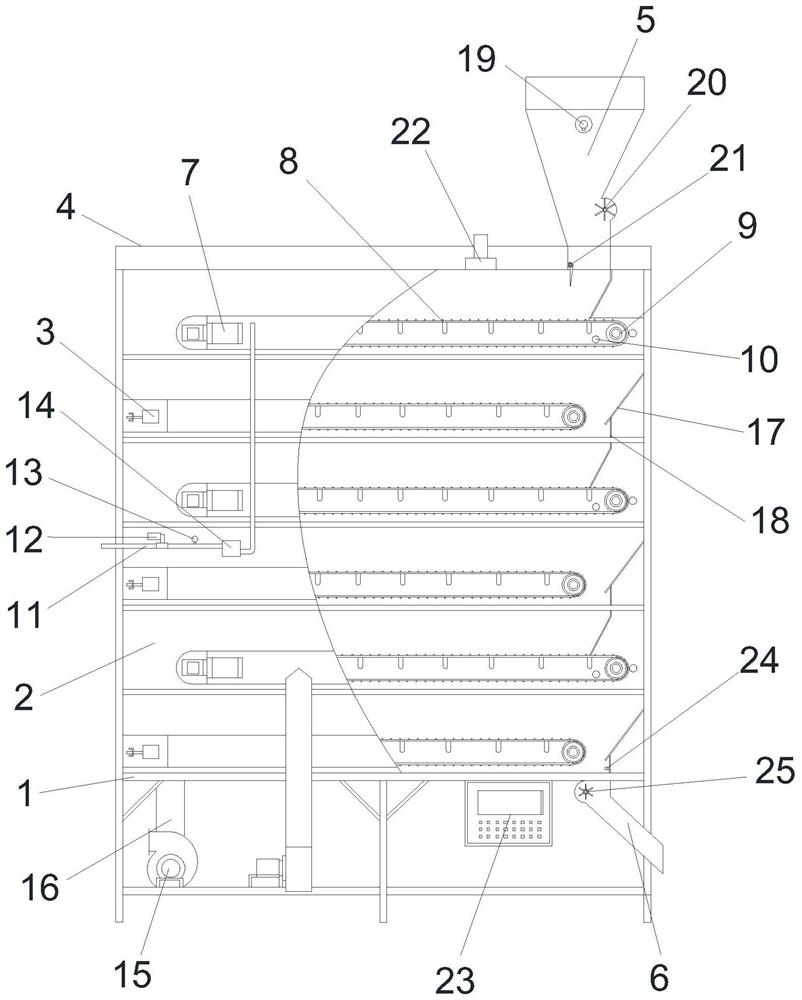

Multi-layer reciprocating chain belt type bran steaming machine

A bran steamer and chain-belt technology, which is applied in the field of wine making, can solve problems such as low operating efficiency, large floor space, and uneven heat transfer, and achieve uniform heating, improved effect, and good steaming and cooling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

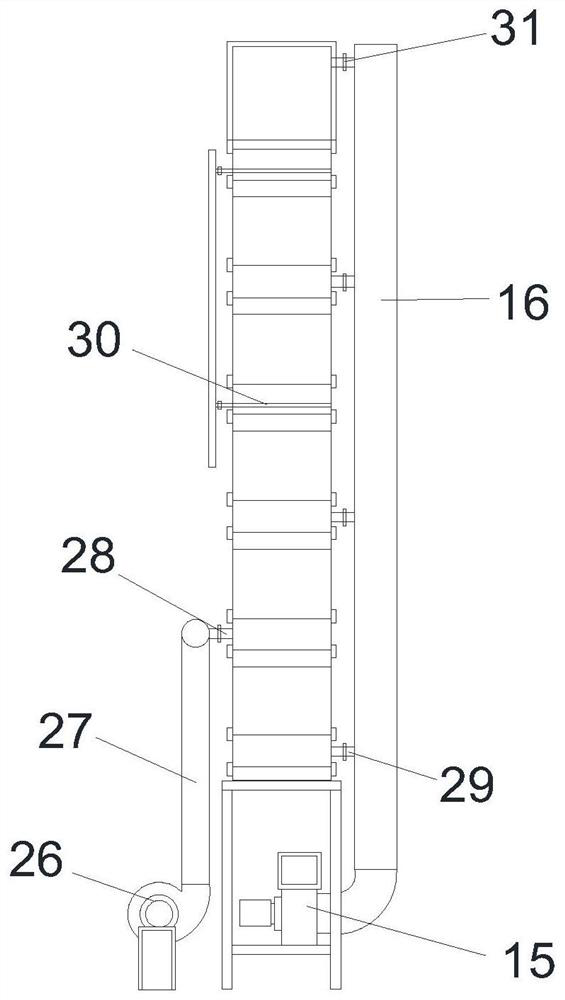

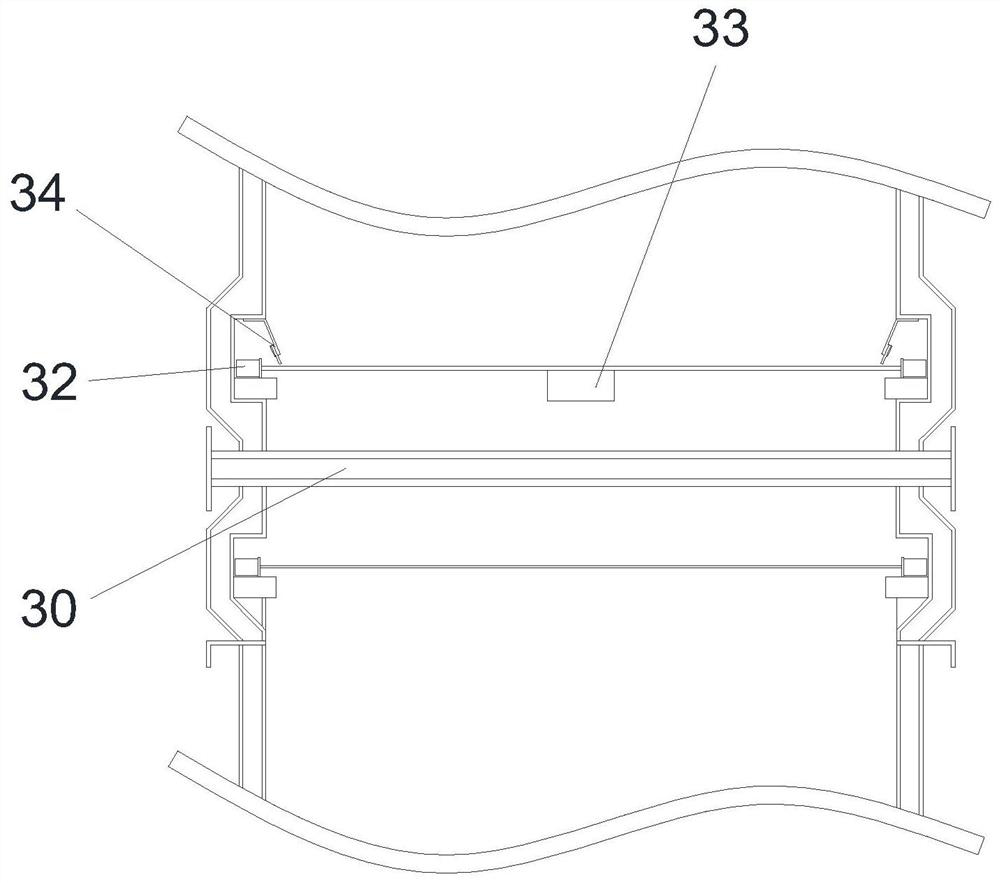

[0028] Embodiment: a kind of multi-layer reciprocating chain-belt steaming machine, such as Figure 1-Figure 4 As shown in the figure, it includes a machine base 1, a multi-layer box body 2 is arranged above the machine base 1, and a set of multi-layer chain belt conveying devices 3 is arranged in each layer of the box body. , the top of the multi-layer box body 2 is fixedly installed with an upper cover 4, and the top right end of the upper cover 4 is provided with a feeding bin 5, the feeding bin 5 and the interior of the multi-layer box body 2 are connected to each other, and the bottom of the multi-layer box body 2 A discharge mechanism 6 is provided, and the inside of the discharge mechanism 6 and the multi-layer box body 2 are communicated with each other, and the material is guided and transferred to the multi-layer chain belt conveyor 3 inside the multi-layer box body 2 through the feeding bin 5. 6. Export the processed materials inside the multi-layer box 2;

[0029]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com