Flexible composite film, flexible oil bag comprising flexible composite film and storage tank

A composite film, flexible technology, used in packaging, packaged food, household packaging, etc., can solve problems such as weakening, and achieve the effect of ensuring tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

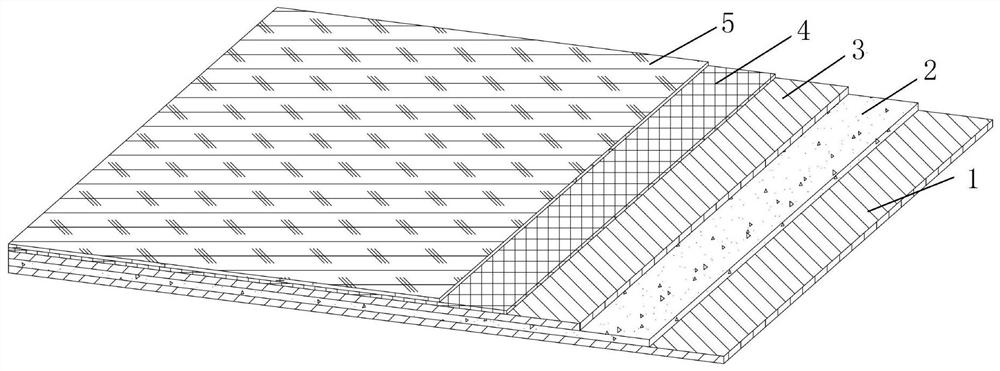

[0051] This embodiment discloses a flexible composite film, as attached figure 1 As shown: including the first oil-resistant layer 1, and the polyester woven fabric 2, the second oil-resistant layer 3, the barrier layer 4 and the static dissipative layer 5 covered in sequence on the inner surface of the first oil-resistant layer 1;

[0052] The tensile strength of the flexible composite film is ≥92MPa; and Shore 80D≤hardness≤Shore 90D.

[0053] In another embodiment, the first oil-resistant layer 1 and the second oil-resistant layer 3 are both oil-resistant thermoplastic elastomer materials.

[0054] In another embodiment, the barrier layer 4 is a barrier-type thermoplastic elastomer material with a thickness of ≤500 μm; at room temperature, the passing rate of No. 92 and No. 95 gasoline is ≤0.1 g / m 2 .

[0055] In another embodiment, the static dissipative layer 5 is an ion-conductive elastomer material, and its surface conductivity at normal temperature is less than or equ...

Embodiment 2

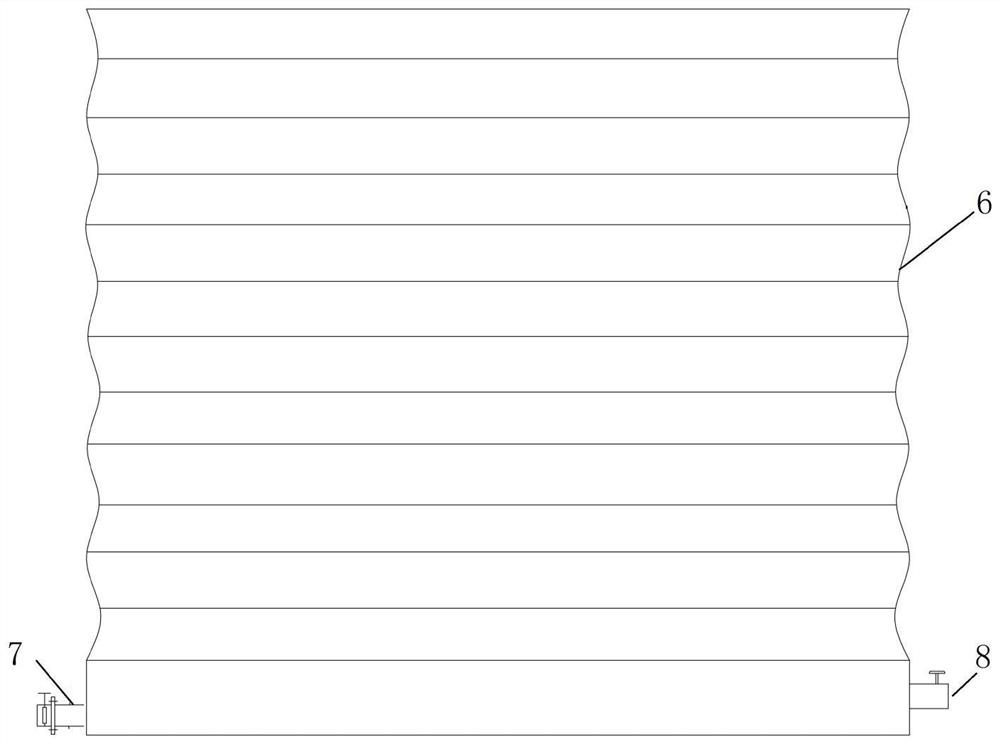

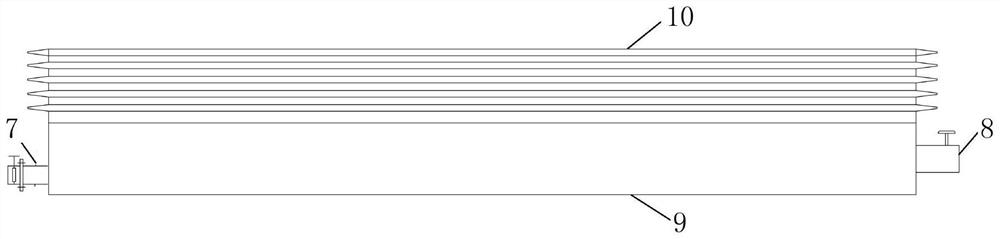

[0058] This embodiment discloses a flexible oil bladder, as attached Figure 2-3 As shown, including: folding oil bag 6, non-drip valve 7 and filling port 8;

[0059] Wherein, the folded oil bag 6 is made of the flexible composite film described in Embodiment 1;

[0060] The non-drip valve 7 and the filling port 8 are all located outside the folded oil bag 6 .

[0061] In another embodiment, the folded oil bag 6 includes: a fixed part 9 and a folded part 10 ; the non-drip valve 7 and the filling port 8 are located outside the fixed part 9 .

Embodiment 3

[0063] This embodiment discloses a storage tank, as attached Figure 4-5 As shown, including the flexible oil bag of embodiment 2, it also includes: tank body 11, floating plate 12, non-drip valve 7, filling port 8 and tank body manhole 13;

[0064] Wherein, the bottom of the fixing part 9 is fixedly connected with the inner bottom of the tank body 11, and the non-drip valve 7 and the filling port 8 extend from the outer end of the fixing part 9 to the outside of the tank body 11;

[0065] The top of the folding part 10 is fixedly connected to the bottom of the floating plate 12;

[0066] The tank manhole 13 extends to the inside of the fixing part 9 .

[0067] In another embodiment, the bottom of the fixing part 9 and the bottom of the tank body 11 are fixed by gluing.

[0068] In another embodiment, the top of the folding part 10 and the bottom of the floating plate 12 are fixedly connected by glue coating and a flange pressing plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com