Tapper for fire-fighting construction

A hole saw and fire-fighting technology, which is applied in the direction of manufacturing tools, boring/drilling, metal processing equipment, etc., can solve the problems of user scratches, inability to adapt to pipe opening, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

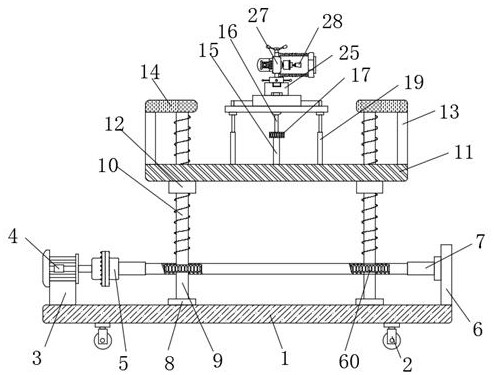

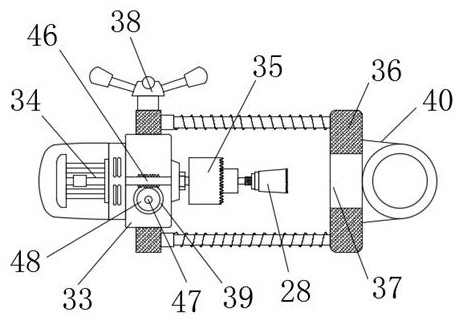

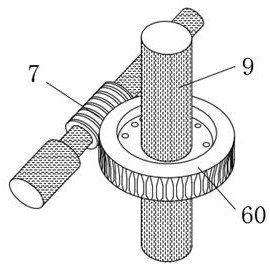

[0034] See Figure 1-11 , In the embodiment, an opening with a fire protection construction embodiment of the present invention includes a base 1, the base 1 is mounted below the positioning wheel 2, the base 1 is mounted on an elevating structure, positioning structure mounted on the lift structure, mounted on the positioning structure dynamic structure 27, dynamic opening structure 27 is mounted on the structure 28, 28 comprises an open cell structure 57 and the upper connecting rod 58 opening the cover, the opening structure 28 by a connecting rod 57 fixedly mounted on the power structure 27, the opening cover 58 an opening 59 is provided with teeth, the opening 58 inside the top cover fixing lever 54 is attached to the wind, the wind rod 54 is fixedly mounted a plurality of blades 55 set negative pressure, opening the cover 58 defines a peripheral side of the symmetry of an amount of four outlet 56, the opening cover 58 rotates under the action of opening the power system, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com