Hot bath forming process of high-corrosion-resistance and easy-to-weld hot-pressing part

A forming process and component technology, which is applied in the field of hot bath forming process of high corrosion resistance and easy to weld hot-pressed components, can solve the problems of difficult control of pre-cooling temperature, difficulty in uniform and controllable cleaning of extremely thin surface oxide layer, and achieve Reduce processing and manufacturing costs, reduce mold damage, and improve tissue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

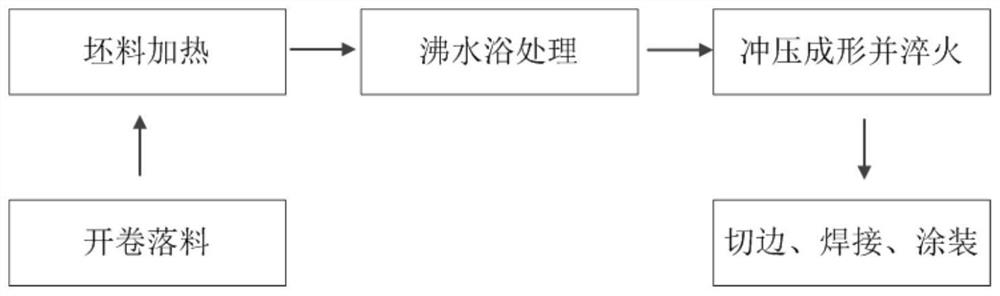

[0043] A hot-bath forming process for high-corrosion-resistant and easy-to-weld hot-pressed parts, such as figure 1 shown, including the following steps:

[0044] S1, 1.5mm thick galvanized hot-formed steel sheet (matrix composition includes C 0.18-0.21wt%, Si 0.05-0.2wt%, Mn 1.5-2.2wt%, Cr 0-0.3wt%, Mo 0-0.25wt% , Ti 0.02-0.04wt%, Nb 0-0.1wt%, B 0.002-0.006wt%, P 0-0.020wt%, S 0-0.003wt%, Al 0.02-0.06wt%, N 0-0.006wt%; Double GI surface galvanized 150g / m 2 , one side thickness 11um) transferred to 890 ℃ box-type heating furnace, heat preservation 5min, complete austenitization; the oxygen content (volume fraction) of the atmosphere in the heating furnace is 20%.

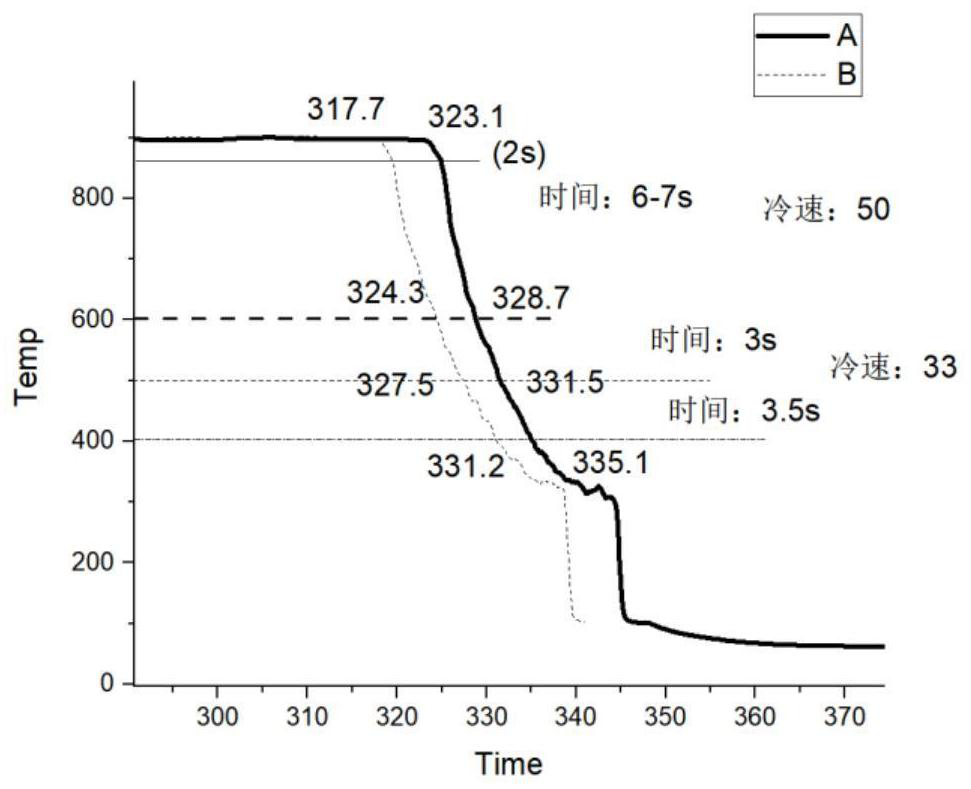

[0045] S2. After the heating is completed, the plate is transferred to the boiling water tank, immersed in boiling water for even cleaning and cooling, the depth is 3-1000mm, and the boiling water temperature is 100°C; the residence time of the steel plate in the boiling water is 6s.

[0046] S3. Since the mold i...

Embodiment 2

[0050] A hot bath forming process for highly corrosion-resistant and easy-to-weld hot-pressed parts, comprising the following steps:

[0051] S1, plate thickness 1.5mm galvanized hot-formed steel sheet (matrix composition includes C 0.05-0.35wt%, Si 0.05-0.2wt%, Mn 0.5-2.5wt%, Cr 0-0.3wt%, Mo 0-0.25wt% , Ti 0.02-0.04wt%, Nb 0-0.2wt%, V 0-0.2wt%, B 0.002-0.006wt%, P 0-0.020wt%, S 0-0.003wt%, Al 0.02-0.06wt%, N 0-0.006wt%, the remaining elements are Fe; double GA surface galvanized 150g / m 2 , thickness 11um on one side) was transferred to a 900°C box-type heating furnace and held for 5 minutes to complete austenitization; the oxygen content (volume fraction) of the atmosphere in the heating furnace was 20%.

[0052] S2. After the heating is completed, the plate is transferred to the boiling water tank, immersed in boiling water to wash evenly and cool down. The depth of the plate is 3-1000mm, and the boiling water temperature is 80°C; the residence time of the steel plate in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com