Hierarchically porous titanium silicalite molecular sieve coating, preparation method and application thereof

A technology of titanium-silicon molecular sieves and graded pores, which is applied in the direction of molecular sieve catalysts, oxime preparation, chemical instruments and methods, etc., can solve the problems of catalyst sintering deactivation, catalyst easy coking, low thermal conductivity, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this embodiment, honeycomb cordierite is used as the carrier: the pore diameter is 1 mm, and the straight channels of the cordierite carrier account for 90% of the total volume of the material.

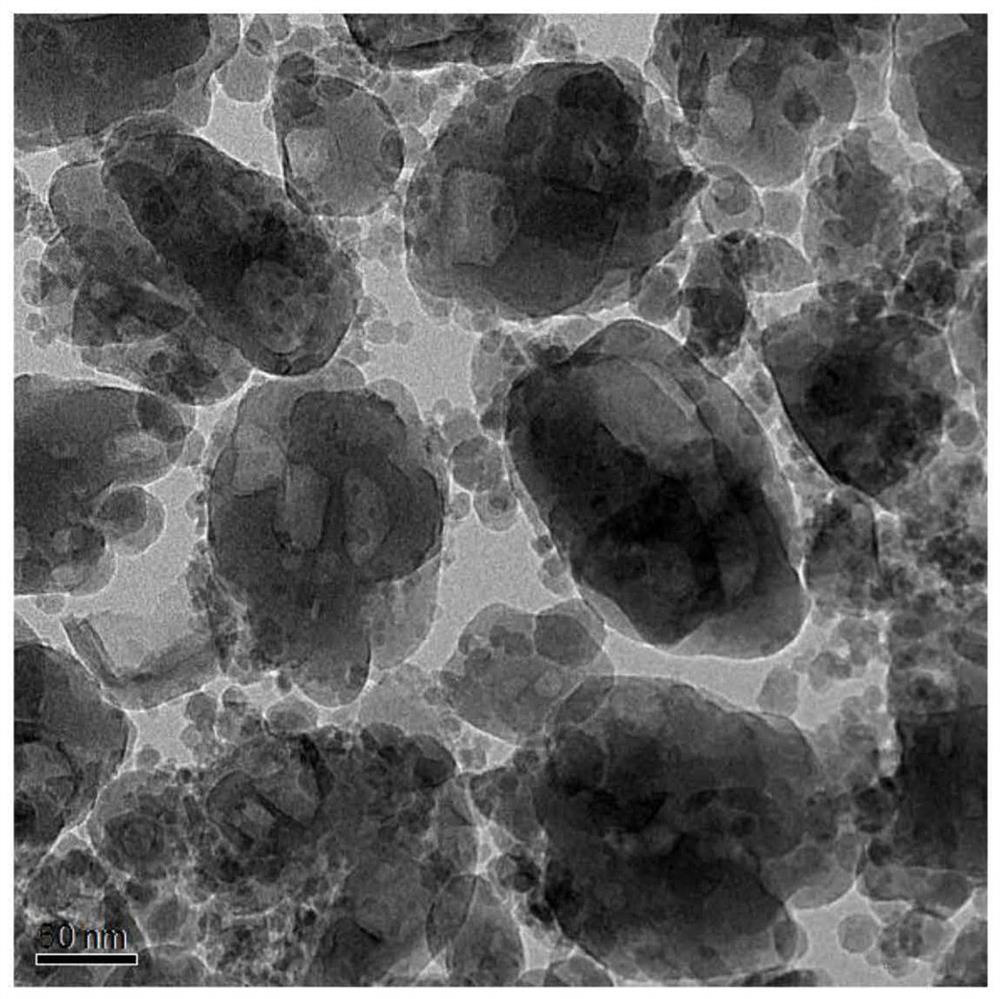

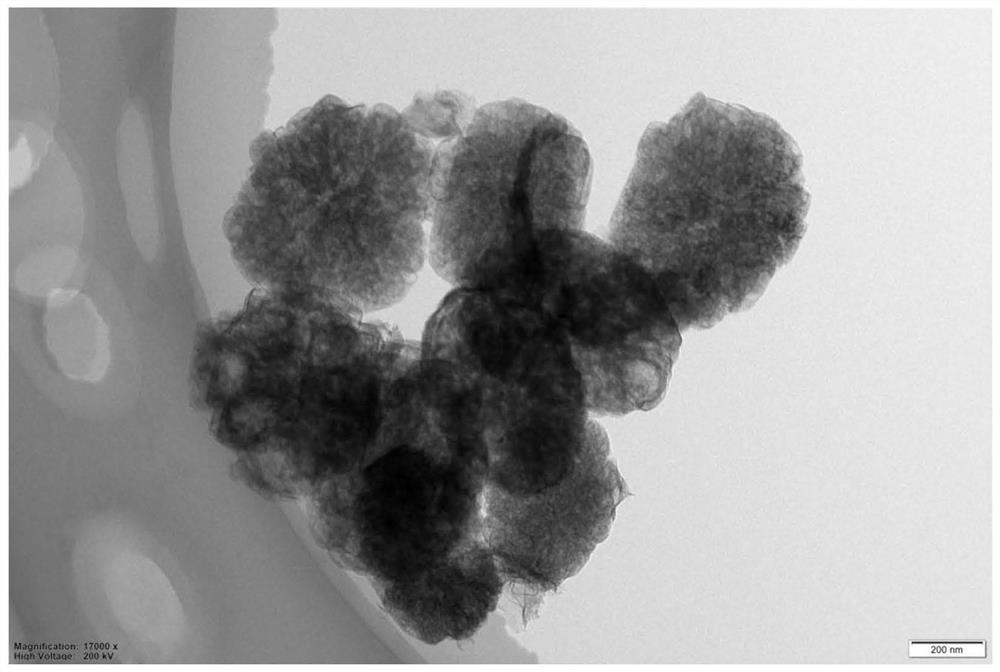

[0032] The preparation method of grade hole TS-1 type molecular sieve coating is as follows: (1) add 20 grams of TS-1 type molecular sieve to 90 grams of deionized water, add 20 grams of silica sol, 2 grams of carboxymethyl cellulose to make coating slurry material. (2) After coating the honeycomb cordierite ceramics with a diameter of 20 mm and a height of 20 mm in the above coating slurry for 3 times, they were treated in a 100 degree oven for 12 hours. (3) The above materials were treated in tetrapropylammonium hydroxide vapor at 180 degrees for 48 hours. (4) After the sample treated with tetrapropylammonium hydroxide steam was treated at 100 degrees for 12 hours, it was roasted at 550 degrees for 6 hours. Thus, the titanium-silicon molecular sieve coating with the holl...

Embodiment 2

[0037] In this embodiment, stainless steel wire mesh is used as the carrier: the pore diameter is 100 microns, and the pores account for 95% of the total volume of the material.

[0038] The preparation method of graded hole TS-1 molecular sieve coating is as follows: (1) Add 20 grams of TS-1 molecular sieve to 90 grams of deionized water, add 20 grams of titanium sol, and 2 grams of carboxymethyl cellulose to make a coating slurry . (2) After coating a stainless steel wire mesh disc with a thickness of 5 mm and a diameter of 20 mm in the above-mentioned coating slurry once, it was treated in a drying oven at 100 degrees for 12 hours, and baked at 550 degrees for 6 hours. (3) The above materials were treated at 160°C for 12 hours in a mixed solution of 0.5 mol / liter tetrapropylammonium hydroxide and 0.1 mol / liter sodium hydroxide. (4) After the sample treated with the tetrapropylammonium hydroxide solution was treated at 100°C for 12 hours, it was roasted at 550°C for 6 hours...

Embodiment 3

[0043] In this embodiment, foamed alumina ceramics are used as the carrier: the pore diameter is 2 mm, and the pores account for 80% of the total volume of the material.

[0044] The preparation method of grade hole TS-1 type titanium-silicon molecular sieve coating is as follows: (1) add 20 grams of TS-1 type molecular sieve modified by copper element into 80 grams of deionized water, add 30 grams of silica sol, 5 grams of polyethylene glycol Alcohol to make coating slurry. (2) After coating the foamed alumina ceramics with a diameter of 20 mm and a height of 20 mm in the above-mentioned coating slurry for 5 times, they were treated in a drying oven at 100 degrees for 12 hours, and baked at 550 degrees for 6 hours. (3) The above materials were treated at 160°C for 12 hours in a mixed solution of 0.2 mol / L tetrapropylammonium hydroxide and 0.1 mol / L sodium hydroxide. (4) After the sample treated with the tetrapropylammonium hydroxide solution was treated at 100°C for 12 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com