Six divine comedies and preparation method of six divine comedies

A technology of Liushenqu and fermentation substrate, which is applied in the field of preparation of Liushenqu and Liushenqu, can solve problems such as reducing the production efficiency of enterprises, and achieve the effects of accelerating the fermentation speed, increasing the fermentation speed and improving the production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] S1: Grind 1 part of bitter almond and 1 part of red bean into powder, and mix them with 25 parts of flour and 50 parts of wheat bran to obtain a pre-medicated powder; decoct 5 parts of Polygonum japonica, 5 parts of Artemisia annua, and 5 parts of Cocklebur in water After 1 hour, the filtrate was concentrated into a clear paste.

[0022] S2: Mix the premedicated powder, clear cream and appropriate amount of water to prepare a fermentation substrate with a water content of 25%.

[0023] S3: Put the fermentation substrate in a sterilizer, heat it to 80° C., and keep it for 30 minutes to complete the sterilization of the fermentation substrate.

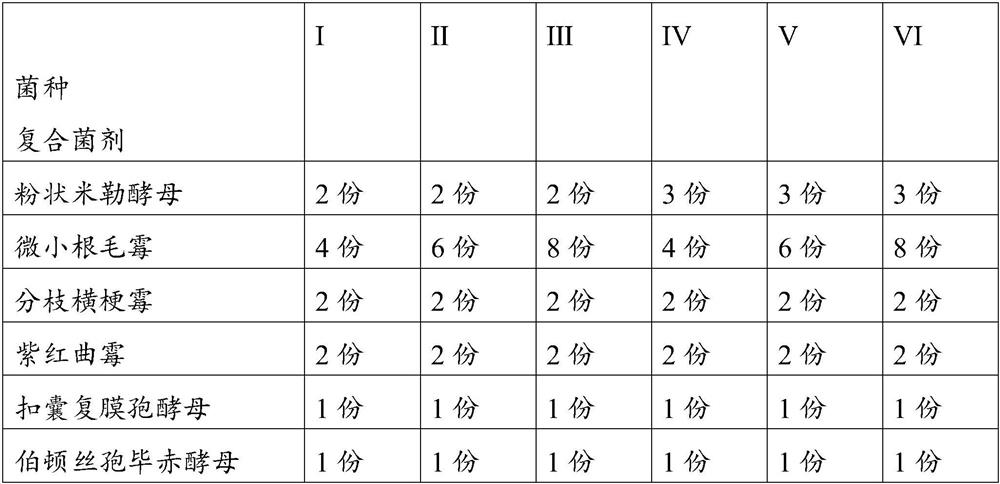

[0024] S4: Mix the compound microbial agent I with the sterilized fermentation substrate according to the mass ratio of 1:10, and spread it on each layer in the fermentation tank, and the thickness of each layer is less than or equal to 20cm. The temperature in the fermentation tank was kept at 25° C., and the relative humidity w...

Embodiment 2

[0027] S1: Grind 1 part of bitter almond and 1 part of red bean into powder, and mix them with 25 parts of flour and 50 parts of wheat bran to obtain a pre-medicated powder; decoct 5 parts of Polygonum japonica, 5 parts of Artemisia annua, and 5 parts of Cocklebur in water After 1 hour, the filtrate was concentrated into a clear paste.

[0028] S2: Mix the premedicated powder, clear cream and appropriate amount of water to prepare a fermentation substrate with a water content of 32%.

[0029] S3: Put the fermentation substrate in a sterilizer, heat it to 80° C., and keep it for 30 minutes to complete the sterilization of the fermentation substrate.

[0030] S4: Mix the compound microbial agent II with the sterilized fermentation substrate according to the mass ratio of 1:55, spread it on each layer in the fermentation tank, and the thickness of each layer is less than or equal to 20cm. The temperature in the fermentation tank was kept at 28° C., and the relative humidity was ...

Embodiment 3

[0033] S1: Grind 1 part of bitter almond and 1 part of red bean into powder, and mix them with 25 parts of flour and 50 parts of wheat bran to obtain a pre-medicated powder; decoct 5 parts of Polygonum japonica, 5 parts of Artemisia annua, and 5 parts of Cocklebur in water After 1 hour, the filtrate was concentrated into a clear paste.

[0034] S2: Mix the premedicated powder, clear cream and appropriate amount of water to prepare a fermentation substrate with a water content of 40%.

[0035] S3: Put the fermentation substrate in a sterilizer, heat it to 80° C., and keep it for 30 minutes to complete the sterilization of the fermentation substrate.

[0036] S4: Mix the compound microbial agent III with the sterilized fermentation substrate according to the mass ratio of 1:100, and spread it on each layer in the fermentation tank, and the thickness of each layer is less than or equal to 20cm. The temperature in the fermentation tank was kept at 32° C., and the relative humidit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com