Air cathode of aluminum air battery, and preparation method thereof

An aluminum-air battery and air cathode technology, which is applied to battery electrodes, fuel cell-type half-cells, primary battery-type half-cells, circuits, etc., can solve the problems of high cost of graphene preparation and limited practical application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

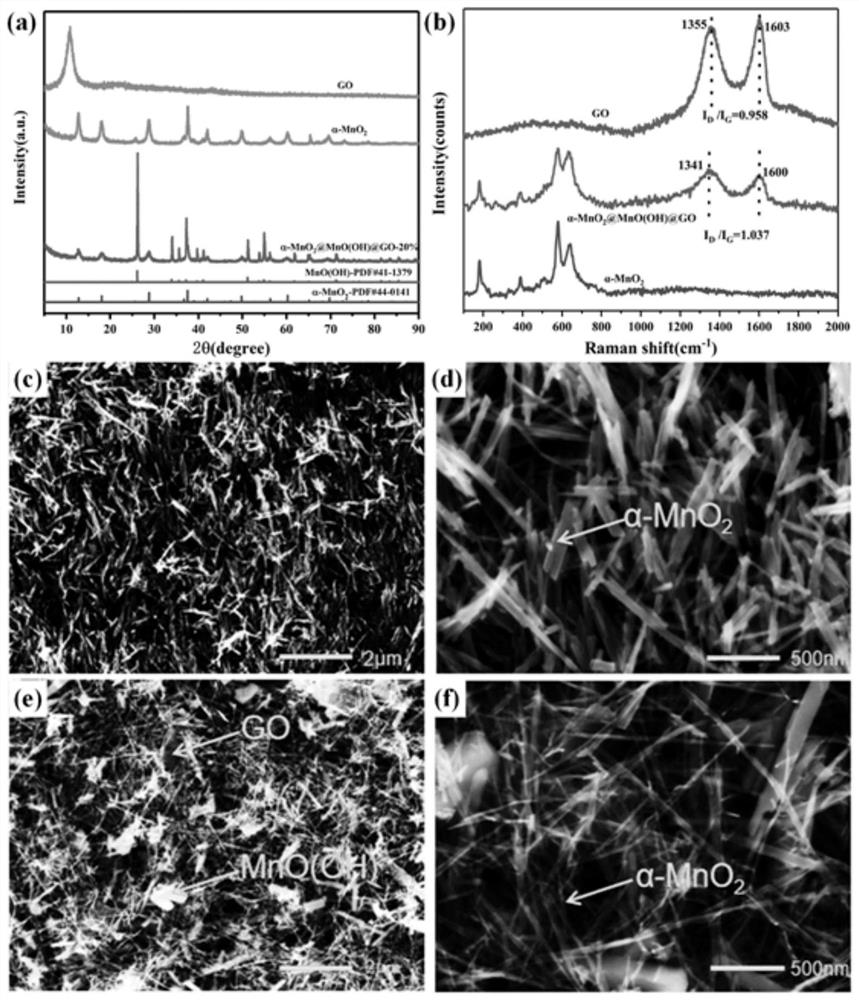

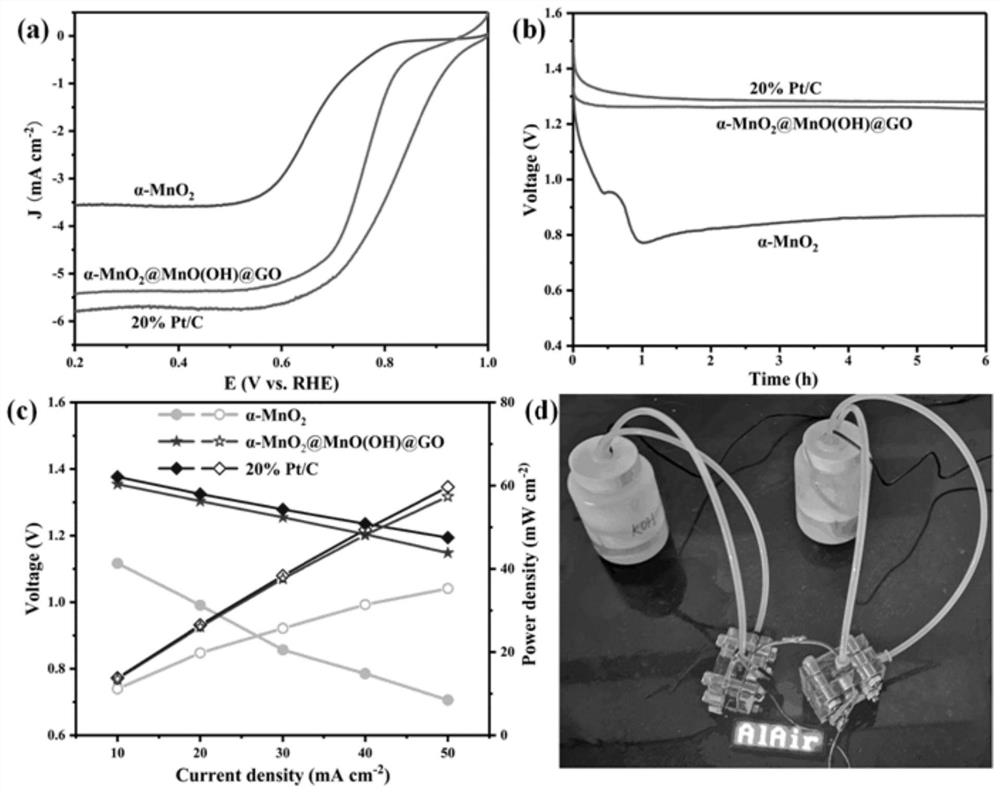

[0037] Step 1: Combine GO, KMnO 4 and MnSO 4 The powder was mixed and poured into a beaker according to the mass ratio of 1.5:2:2, then an appropriate amount of deionized water was added, supplemented by ultrasonic treatment, the ultrasonic treatment time was 10min, and the ultrasonic amplitude was 40%, to obtain uniformly dispersed GO, KMnO 4 and MnSO 4 Mix the solution, transfer the mixed solution to a polytetrafluoroethylene-lined hydrothermal reaction kettle, heat it at 120°C for 15 hours, collect the precipitate after the reaction, and centrifuge at a speed of 15000r / min for 10 minutes, and wash it three times Dry to get α-MnO 2 @MnO(OH)@GO composites.

[0038] Step 2: the α-MnO obtained in step 1 2 The @MnO(OH)@GO composite material was mixed with conductive carbon black and polytetrafluoroethylene emulsion (58% solid content) at a mass ratio of 1:2:1, and then ultrasonically dispersed by adding an appropriate amount of absolute ethanol (ultrasonic amplitude of 20% ...

Embodiment 2

[0045] Step 1: Combine GO, KMnO 4 and MnSO 4 The powder was mixed and poured into a beaker according to the mass ratio of 2:2.5:1.5, and then an appropriate amount of deionized water was added, supplemented by ultrasonic treatment, the ultrasonic treatment time was 15min, and the ultrasonic amplitude was 60%, to obtain uniformly dispersed GO and KMnO 4 and MnSO 4 Mix the solution, transfer the mixed solution to a polytetrafluoroethylene-lined hydrothermal reaction kettle, keep it warm at 160°C for 20 hours, collect the precipitate after the reaction, and use the centrifugal speed: 15000r / min, centrifugal time 15min, after centrifugal washing 5 times Dry to get α-MnO 2 @MnO(OH)@GO composites.

[0046] Step 2: the α-MnO obtained in step 1 2 The @MnO(OH)@GO composite material was mixed with conductive carbon black and polytetrafluoroethylene emulsion (63% solid content) at a mass ratio of 1.5:3:2, and then ultrasonically dispersed by adding an appropriate amount of absolute e...

Embodiment 3

[0048] Step 1: Combine GO, KMnO 4 and MnSO 4 The powder was mixed according to the mass ratio of 2:2.5:1 and poured into a beaker, then an appropriate amount of deionized water was added, supplemented by ultrasonic treatment, the ultrasonic treatment time was 12min, and the ultrasonic amplitude was 50%, to obtain uniformly dispersed GO, KMnO 4 and MnSO 4 Mix the solution, transfer the mixed solution to a polytetrafluoroethylene-lined hydrothermal reaction kettle, keep it warm at 150°C for 16 hours, collect the precipitate after the reaction, and use the centrifugal speed: 12000r / min, centrifugal time 12min, after centrifugal washing 4 times Dry to get α-MnO 2 @MnO(OH)@GO composites.

[0049] Step 2: the α-MnO obtained in step 1 2 @MnO(OH)@GO composite material is mixed with conductive carbon black and polytetrafluoroethylene emulsion (60% solid content) at a mass ratio of 1.5:2:2, and then ultrasonically dispersed by adding an appropriate amount of absolute ethanol (ultras...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com