Large-area perovskite light-emitting film and light-emitting diode thereof

A technology of light-emitting diodes and light-emitting films, which is applied in the manufacture of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of non-dense perovskite light-emitting films, high solution waste rate, low light-emitting efficiency, etc. Dense, smooth surface and uniform luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

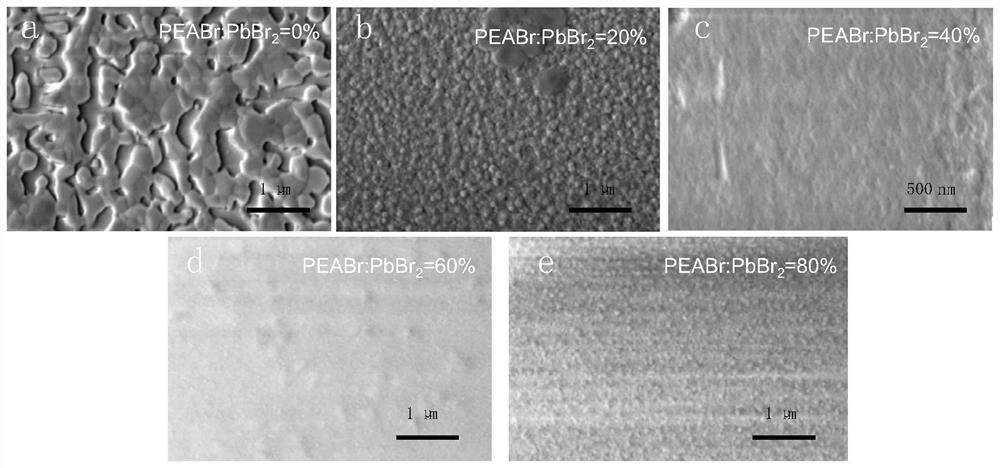

[0047] Preparation of PEABr:CsPbBr with different molar ratios 3 Large-area perovskite thin films:

[0048] (1) Preparation of perovskite precursor solution:

[0049] CsBr and PbBr 2 Soluble in the organic solvent of DMSO in equimolar ratio (CsBr=0.3M, PbBr 2 =0.3M), after mixing evenly, it was divided into five bottles of 1mL solution to prepare a 0.3M perovskite solution. Then add relative CsPbBr to these five bottles of solution 3 Solution molar ratio is 0%, 20%, 40%, 60% and 80% PEABr, obtains the (PEA) containing different molar ratio m (Cs) n-1 Pb n Br 3n+1 Precursor solution of type perovskite.

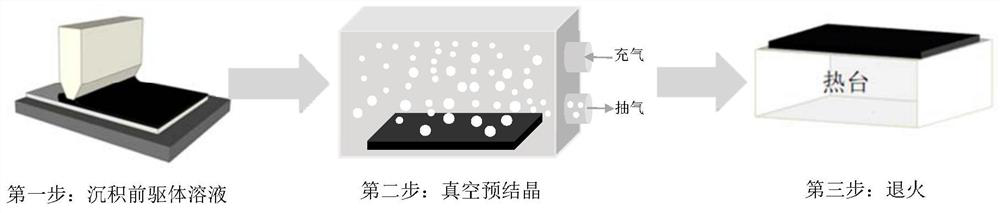

[0050] (2) (PEA) with different n values m (Cs) n-1 Pb n Br 3n+1 The preparation of large-area perovskite thin films of type perovskite is as follows figure 1 Shown:

[0051] In a glove box at a room temperature of 19°C, set the height difference between the scraper and the substrate to 220 μm, drop a volume of 26 μL of the perovskite precursor solution onto the g...

Embodiment 2

[0053] (1) Preparation of perovskite precursor solution:

[0054] 0.5mol CsBr and 0.5mol PbBr 2 Dissolve in DMSO organic solvent, mix well and then add relative to PbBr 2 40% molar ratio of PEABr yields (PEA) with an n value of 5 2 (Cs) 4 Pb 5 Br 16 Precursor solution of type perovskite.

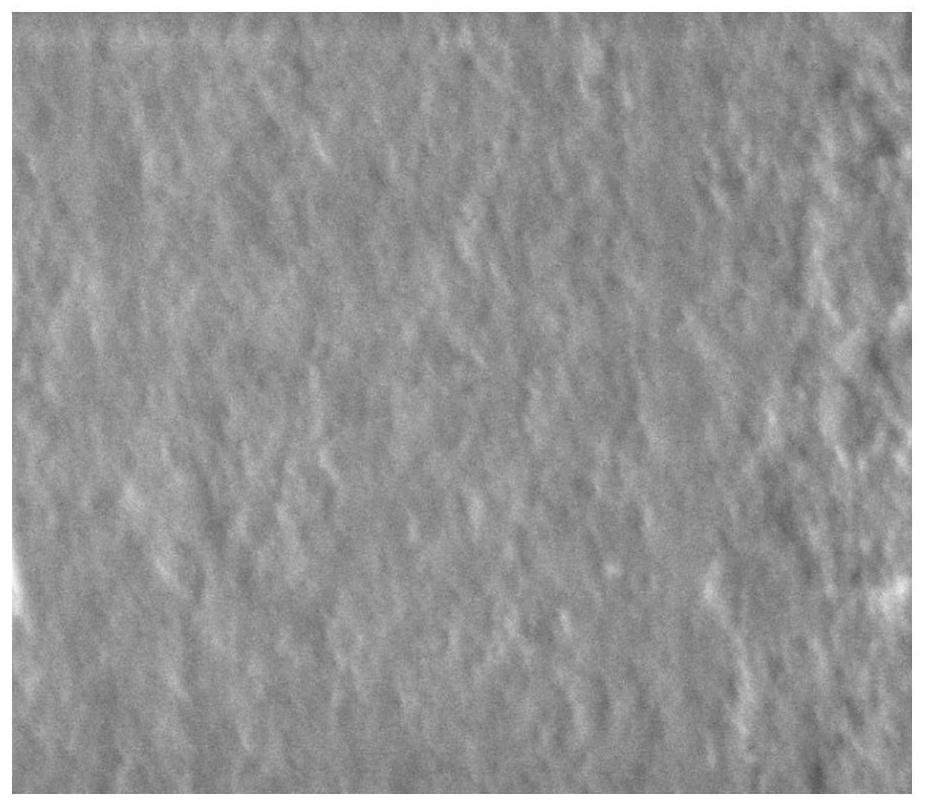

[0055] (2) (PEA) with an n value of 5 2 (Cs) 4 Pb 5 Br 16 The method of preparing large-area perovskite thin films is as described in Example 1: the morphology of the perovskite thin films is as follows image 3 As shown, the thin film is dense, uniform and has high photoluminescence efficiency. Its photoluminescence efficiency is as Figure 7 Shown as high as 32.3%.

Embodiment 3

[0064] Preparation of PEABr:FAPbBr with different molar ratios 3 Large-area perovskite thin films:

[0065] (1) Preparation of perovskite precursor solution:

[0066] FABr and PbBr 2 Soluble in NMP organic solvent in equimolar ratio (CsBr=0.4M, PbBr 2 =0.4M), after mixing evenly, it was divided into five bottles of 1mL solution to prepare a 0.5M perovskite solution. Add relative FAPbBr to these five bottles of solution 3 Solutions with molar ratios of 0%, 20%, 40%, 60% and 80% PEABr obtained different n values of (PEA) m (FA) n-1 Pb n Br 3n+1 Precursor solution of type perovskite.

[0067] (2) (PEA) with different n values m (FA) n-1 Pb n Br 3n+1 The large-area perovskite thin film is prepared, and the preparation method is as described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com