Method for determining molybdenum alloy single crystal slip plane

A molybdenum alloy, plane technology, applied in the preparation of test samples, material analysis using wave/particle radiation, measurement devices, etc., can solve the problem of inaccurate determination of the lack of close packing of the single crystal of molybdenum alloy and the body-centered cubic structure. , the difficulty of sliding plane of single crystal materials, etc., to achieve the effect of improving the determination efficiency, high accuracy and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The method for determining the sliding plane of a molybdenum alloy single crystal in this embodiment includes the following steps:

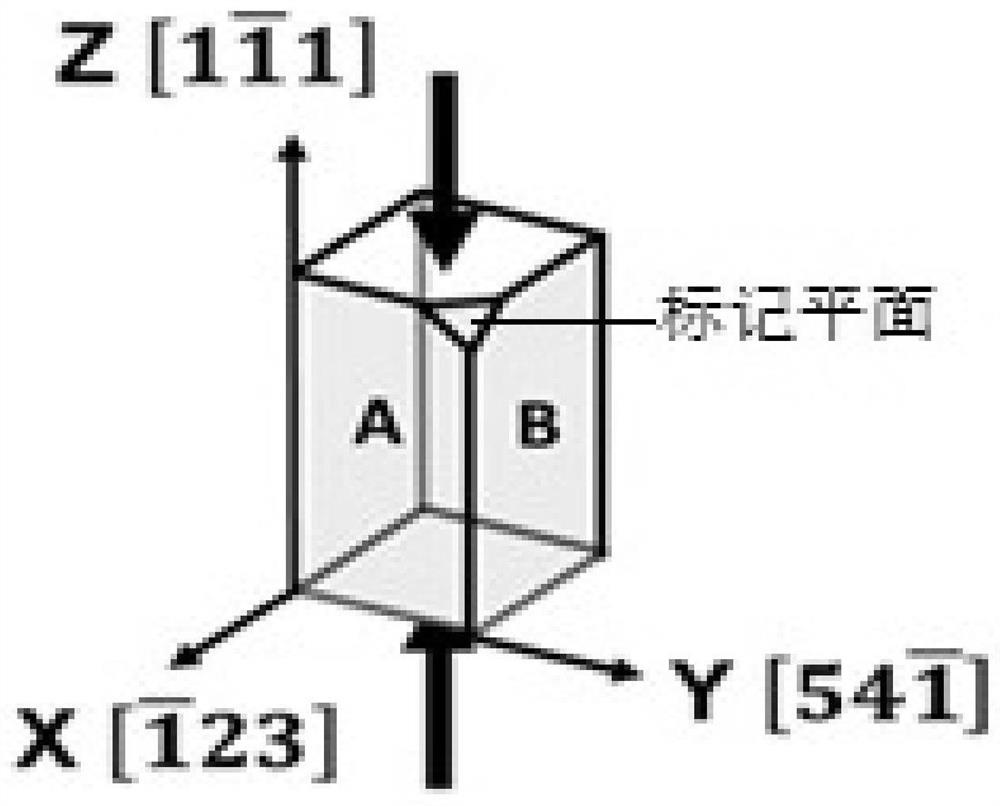

[0025] Step 1. Use wire cutting to cut out the sample on the Mo-3Nb alloy single crystal rod. The specific process is: first align the molybdenum wire used for wire cutting with the bottom surface of the Mo-3Nb alloy single crystal rod, and move along the Mo-3Nb alloy single crystal rod. The axial direction of the alloy single crystal rod starts to move the wire to obtain a cuboid sample with a length×width×height of 7mm×7mm×12mm, and then grinds a small plane at the upper right corner of the intersection vertex of the two sides of the sample As a marked plane; the Mo-3Nb alloy single crystal rod is prepared by the electron beam suspension zone melting method, and the crystal orientation is , such as figure 1 shown;

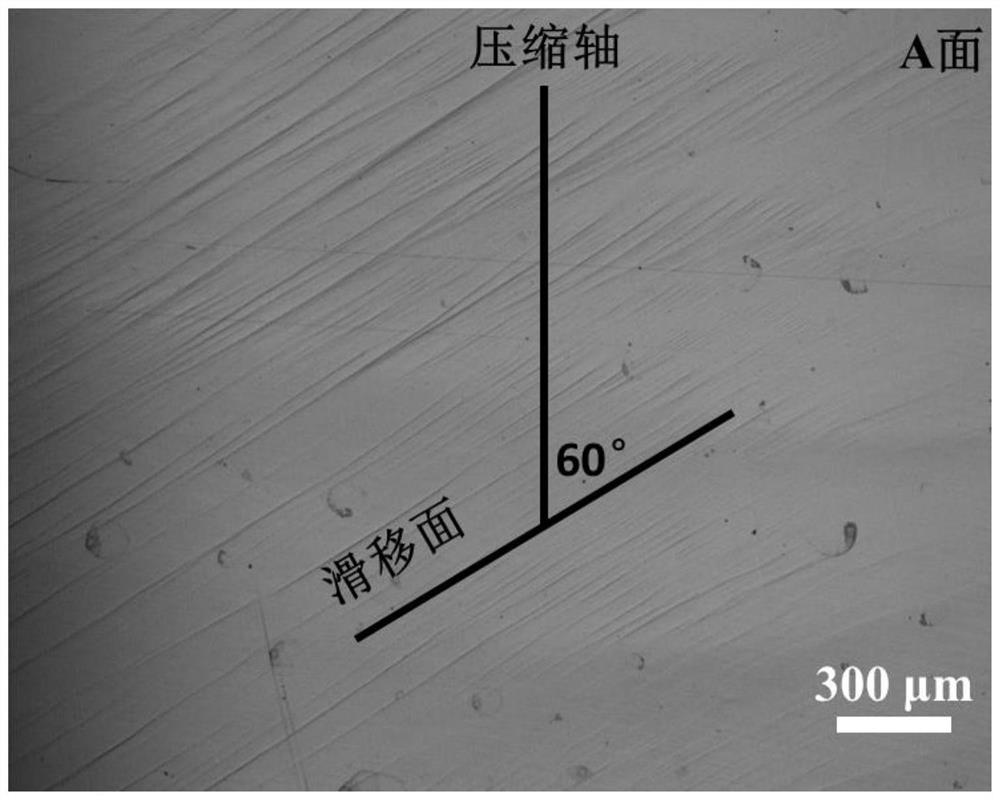

[0026] Step 2. Use the electron backscatter diffraction method (EBSD) to judge the crystal orientation of the side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com