Surface pretreatment process for improving film forming quality of magnesium alloy conversion film

A surface pretreatment, magnesium alloy technology, applied in the direction of metal material coating process, etc., can solve the problems of affecting the quality of film formation, unable to protect the magnesium substrate, and large surface damage, so as to improve the surface quality, improve the surface treatment effect, and improve the quality of the surface. The effect of film quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

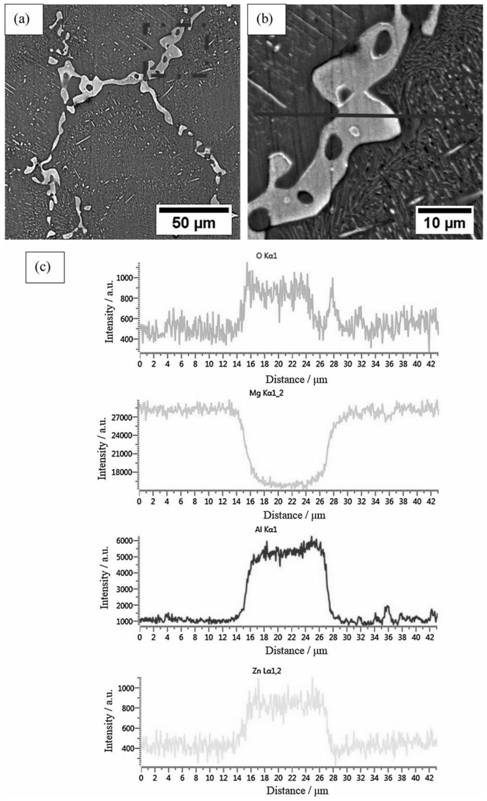

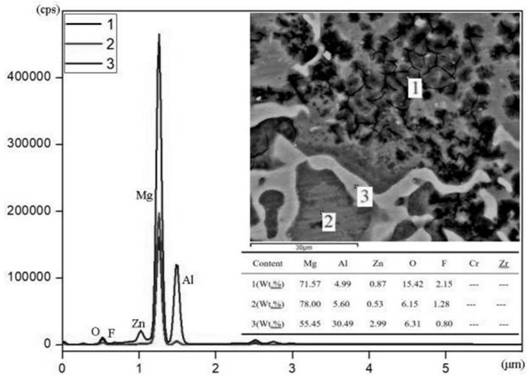

[0015] The surface pretreatment process is to grind and polish the magnesium alloy with 800, 1200, 2000# sandpaper, put it into anhydrous ethanol and ultrasonically clean it for 10 minutes, and use 5-15g / L NaOH+5g / L NaOH 2 CO 3 The solution is used as an alkaline washing solution for alkaline washing at 40-75°C for 5-15 minutes, using 5-15g / L NH 4 HF 2 +1~10g / L C 2 h 2 o 3 ·H 2 O was acid-washed at room temperature for 5-15 s, and finally activated with 10-30 wt.% NaOH at room temperature for 400-800 s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com