Super 13Cr stainless steel surface pickling treatment method

A treatment method and stainless steel technology, applied in the field of metal corrosion and protection, can solve the problems of low Cr content in the pre-passivation film, corrosion resistance damage of the pre-passivation film, etc., to improve corrosion resistance, improve corrosion resistance, reduce The effect of the probability of pitting occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Sample preparation: process the super 13Cr stainless steel into several standard samples with a size of 40mm×10mm×3mm, rinse with clean water, and air-dry for later use;

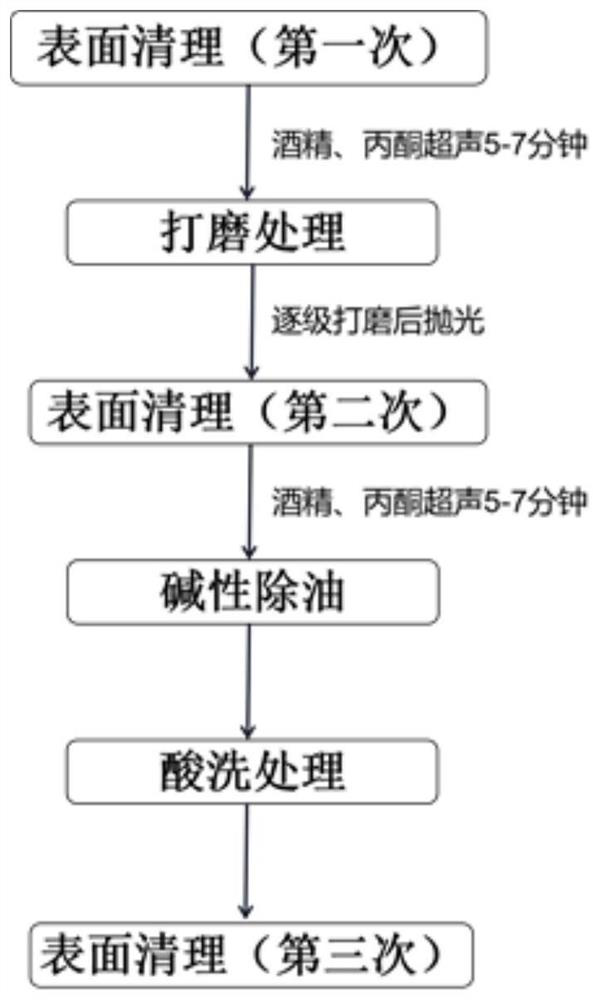

[0036] 2) Surface cleaning: Rinse the super 13Cr stainless steel sample with distilled water, then clean it with acetone and absolute ethanol in an ultrasonic cleaner for the first time, and dry it for later use;

[0037] 3) Grinding treatment: Grind the processed super 13Cr stainless steel sample with sandpaper, and polish it with diamond polishing liquid. Then put the sample into an ultrasonic cleaner and clean it for the second time with acetone and absolute ethanol, and dry it for later use;

[0038] 4) Alkaline degreasing: The cleaned super 13Cr stainless steel sample is placed in an incubator for alkaline degreasing treatment, and the degreasing time is 5 minutes. After degreasing, rinse the sample with distilled water to remove the residual lye on the surface of the sample;

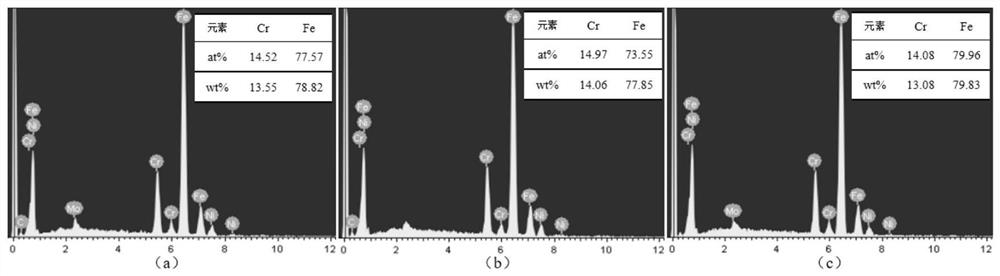

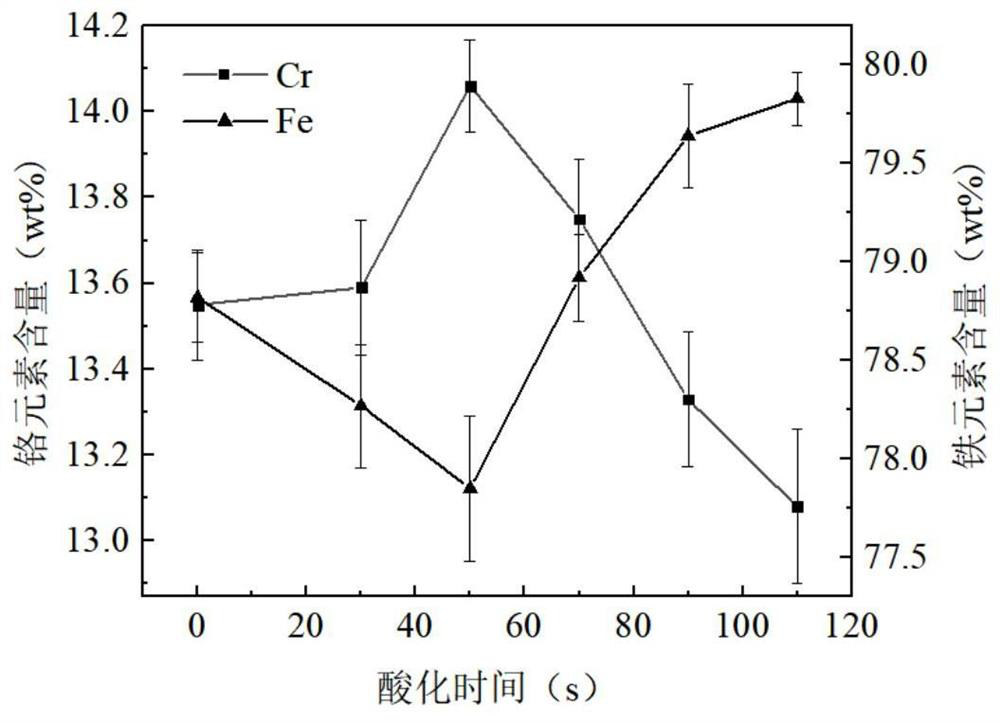

[0039] 5) Sam...

Embodiment 2

[0043] 1) Sample preparation: process the super 13Cr stainless steel into several standard samples with a size of 40mm×10mm×3mm, rinse with clean water, and air-dry for later use;

[0044] 2) Surface cleaning: Rinse the super 13Cr stainless steel sample with distilled water, then clean it with acetone and absolute ethanol in an ultrasonic cleaner for the first time, and dry it for later use;

[0045]3) Grinding treatment: Grind the processed super 13Cr stainless steel sample with sandpaper, and polish it with diamond polishing liquid. Then put the sample into an ultrasonic cleaner and clean it for the second time with acetone and absolute ethanol, and dry it for later use;

[0046] 4) Alkaline degreasing: The cleaned super 13Cr stainless steel sample is placed in an incubator for alkaline degreasing treatment, and the degreasing time is 5 minutes. After degreasing, rinse the sample with distilled water to remove the residual lye on the surface of the sample;

[0047] 5) Pick...

Embodiment 3

[0052] 1) Sample preparation: process the super 13Cr stainless steel into several standard samples with a size of 40mm×10mm×3mm, rinse with clean water, and air-dry for later use;

[0053] 2) Surface cleaning: Rinse the super 13Cr stainless steel sample with distilled water, then clean it with acetone and absolute ethanol in an ultrasonic cleaner for the first time, and dry it for later use;

[0054] 3) Grinding treatment: Grind the processed super 13Cr stainless steel sample with sandpaper, and polish it with diamond polishing liquid. Then put the sample into an ultrasonic cleaner and clean it for the second time with acetone and absolute ethanol, and dry it for later use;

[0055] 4) Alkaline degreasing: The cleaned super 13Cr stainless steel sample is placed in an incubator for alkaline degreasing treatment, and the degreasing time is 5 minutes. After degreasing, rinse the sample with distilled water to remove the residual lye on the surface of the sample;

[0056] 5) Pic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com