Single-component thermosetting polyurethane structural adhesive and preparation method thereof

A polyurethane and structural adhesive technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve problems such as complex production operations, achieve sufficient operating time, and overcome the effects of oxygen inhibition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of diisocyanate oligomers terminated by diols

[0033] Polytetrahydrofuran diol with a molecular weight of 500, BASF

[0034] Liquefied MDI with NCO content of 29 wt% diisocyanate, Wanhua Chemical Group Co., Ltd.

[0035] 100 parts of polytetrahydrofuran diol were dehydrated at 110°C for 1 hour, cooled to 50°C, added 115 parts of liquefied MDI, heated to 80°C under nitrogen protection, and reacted for 2 hours.

[0036] (2) Preparation of double bond-terminated diisocyanate oligomers

[0037] 100 parts of the diol-terminated diisocyanate oligomer prepared in (1) above, 15 parts of hydroxyethyl methacrylate, under the protection of nitrogen, the temperature was raised to 80° C., and the reaction was performed for 2 hours.

[0038] (3) Preparation of blocked isocyanate

[0039] 100 parts of HDI trimer (isophorone diisocyanate, the same below) and 55 parts of methyl ethyl ketoxime were reacted for 3 hours at 60° C. under nitrogen protection to test the NC...

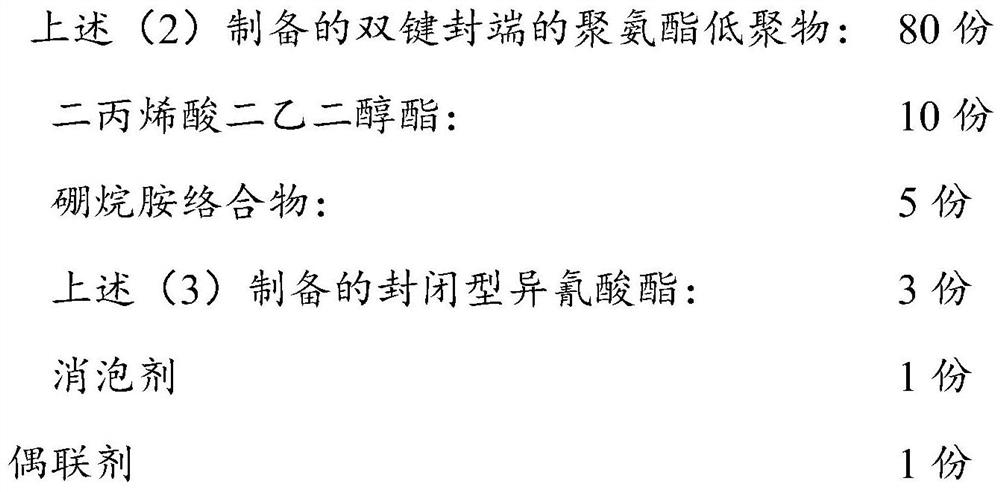

Embodiment 2

[0043] (1) Preparation of diisocyanate oligomers terminated by diols

[0044] Polyether diol with a molecular weight of 500, Dow

[0045] Liquefied MDI NCO content is 29wt% diisocyanate Wanhua Chemical Group Co., Ltd.

[0046] Add 100 parts of polyether diol, heat up to 110°C for vacuum dehydration for 1 hour, cool down to 50°C, add 115 parts of liquefied MDI, raise the temperature to 80°C under nitrogen protection, and react for 2 hours.

[0047] (2) Preparation of double bond-terminated diisocyanate oligomers

[0048] 100 parts of the diisocyanate oligomer prepared in the above (1), 15 parts of hydroxyethyl methacrylate, under the protection of nitrogen, the temperature was raised to 80° C., and the reaction was carried out for 2 hours.

[0049] (3) Preparation of blocked isocyanate

[0050] 100 parts of HDI dimer and 38 parts of methyl ethyl ketoxime were reacted at 60°C for 3 hours under the protection of nitrogen to test the NCO content. When the NCO content was 0, the r...

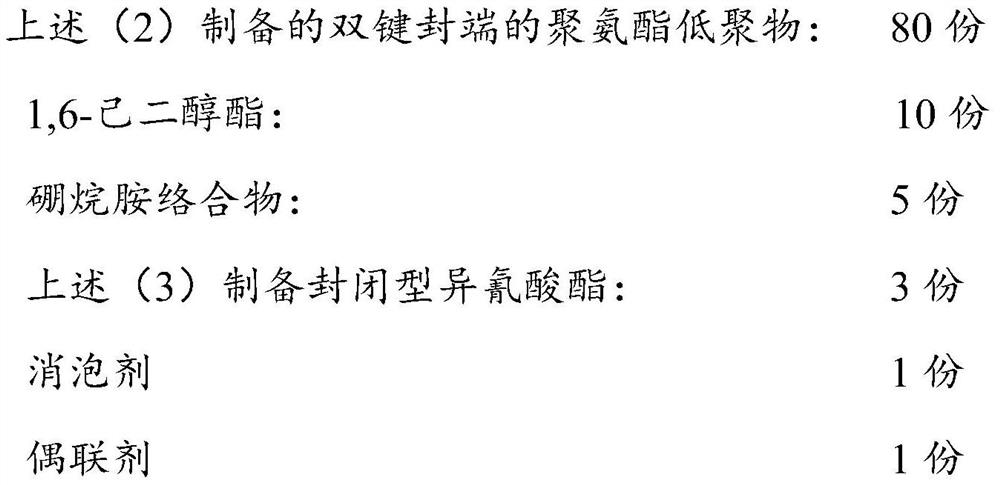

Embodiment 3

[0054] (1) Preparation of diisocyanate oligomers terminated by diols

[0055] Polycaprolactone diol with a molecular weight of 500, Japan Daicel Co., Ltd.

[0056] Liquefied MDI NCO content is 29wt% diisocyanate Wanhua Chemical Group Co., Ltd. adds 100 parts of polycaprolactone diol, heats up to 110°C for vacuum dehydration for 1 hour, cools down to 50°C, adds 115 parts of liquefied MDI, and heats up under nitrogen protection to 80°C and react for 2 hours.

[0057] (2) Preparation of double bond-terminated diisocyanate oligomers

[0058] 100 parts of the diol-terminated diisocyanate oligomer prepared in the above (1) and 13 parts of allyl alcohol were heated up to 80° C. under the protection of nitrogen and reacted for 2 hours.

[0059] (3) Preparation of blocked isocyanate

[0060] 100 parts of liquefied MDI and 40 parts of diethylene glycol monobutyl ether were reacted at 60° C. for 3 hours under nitrogen protection to test the NCO content. When the NCO content was 0, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com