Bio-based reactive polyurethane hot melt adhesive and preparation method thereof

A polyurethane hot-melt adhesive, bio-based technology, applied in the field of polyurethane hot-melt adhesive, can solve the problems of sizing continuity and stability, poor thermal stability, and reactivity not as good as primary hydroxyl group, etc., to improve the moisture curing effect. , good bonding performance, excellent bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation method of bio-based polyester diol A1 is as follows:

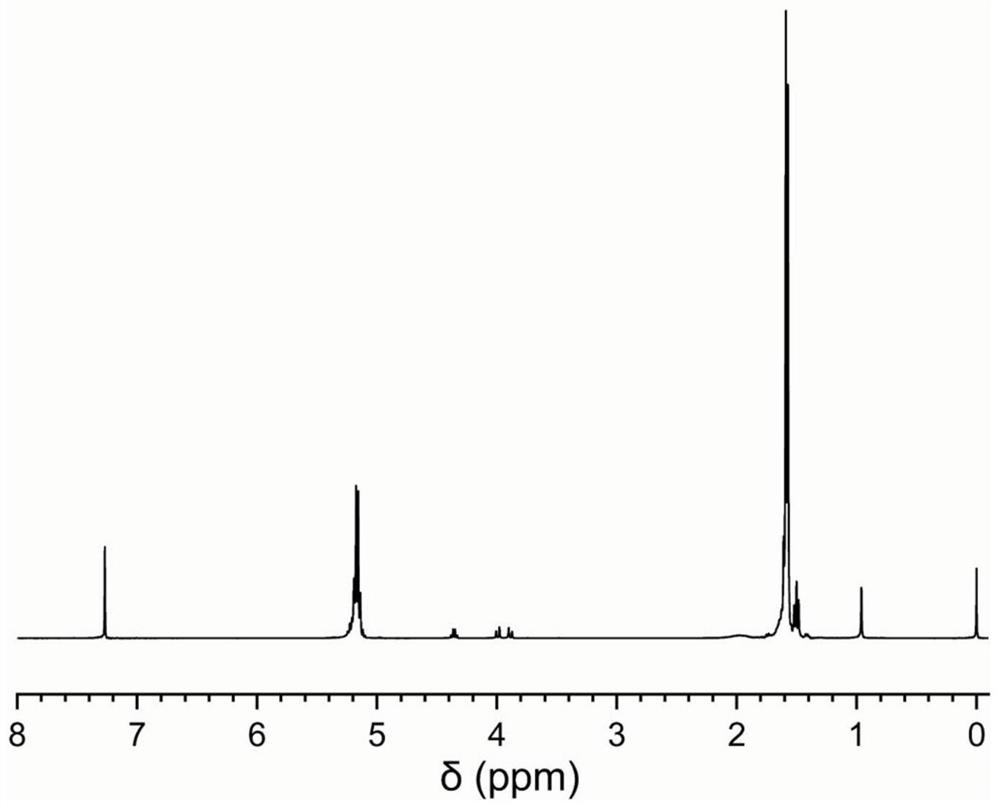

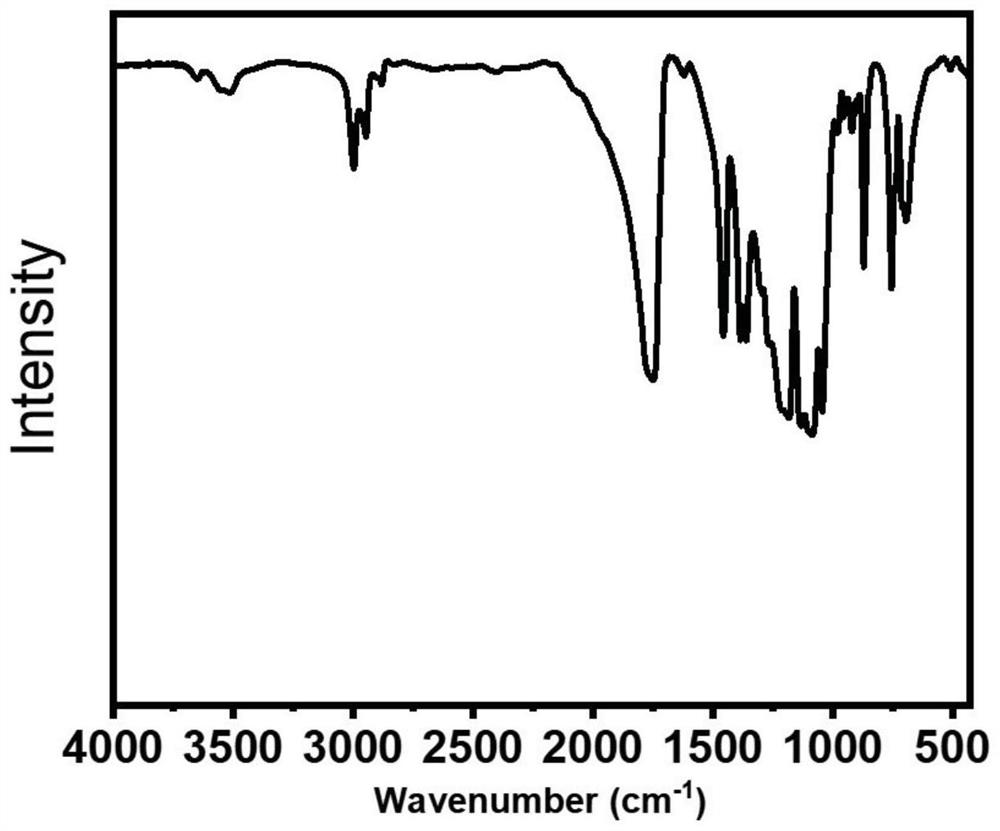

[0041] 38.36 g of ε-caprolactone and 3,9-bis(1,1-dimethyl-2-hydroxyethyl)-2,4,8,10-tetraoxaspiro[5,5]undecyl Add 3.0 g of alkane into the reaction kettle, add 0.15 g of stannous octoate as the second catalyst, raise the temperature to 115°C under the protection of an inert gas, react for 18 hours, and then cool to room temperature to obtain a solid product, which is bio-based polyester diol A1 . Such as figure 1 It is the 1H-NMR figure of the obtained bio-based polyester diol in the present embodiment; figure 2 It is the IR spectrogram of the bio-based polyester diol obtained in this example.

Embodiment 2

[0043] The preparation method of bio-based polyester diol A2 is as follows:

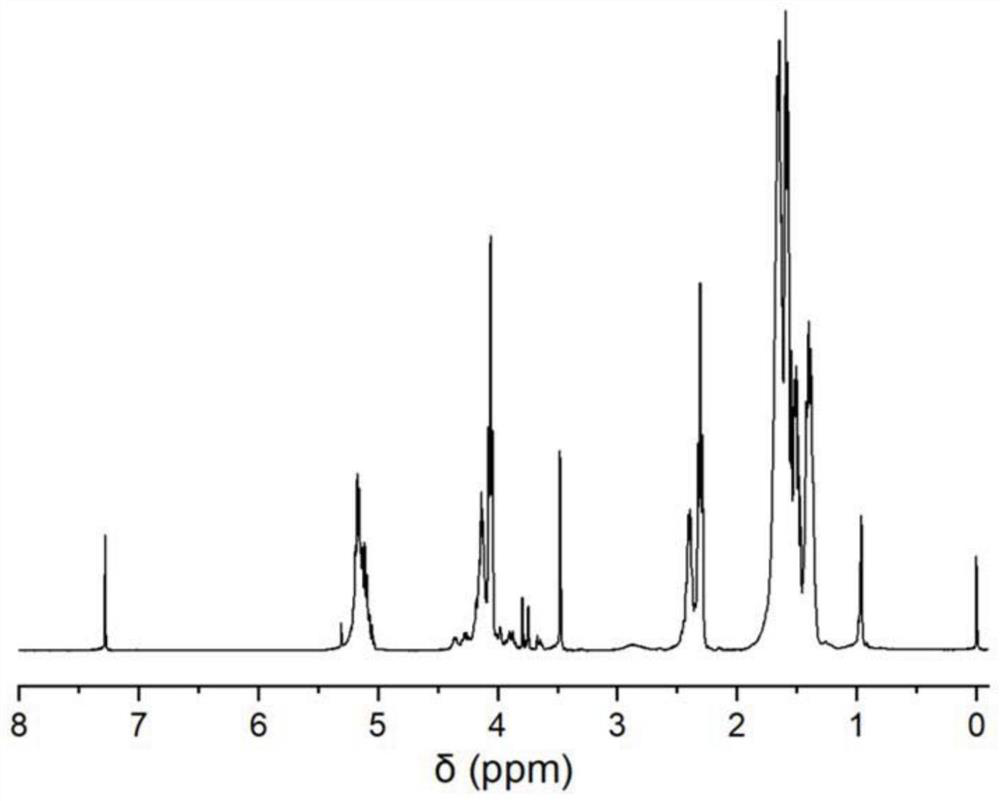

[0044] 38.75g of L-lactide, 7.67g of ε-caprolactone and 3,9-bis(1,1-dimethyl-2-hydroxyethyl)-2,4,8,10-tetraoxaspiro Add 3.0 g of cyclo[5,5]undecane into the reaction kettle, add 0.15 g of stannous octoate as the second catalyst, raise the temperature to 120°C under the protection of an inert gas, react for 20 hours, and then cool to room temperature to obtain a solid product, which is Bio-based polyester diol A2.

Embodiment 3

[0046] The preparation method of bio-based polyester diol A3 is as follows:

[0047] 9.69g of L-lactide, 30.69g of ε-caprolactone and 3,9-bis(1,1-dimethyl-2-hydroxyethyl)-2,4,8,10-tetraoxaspiro Add 3.0 g of cyclo[5,5]undecane into the reaction kettle, add 0.15 g of stannous octoate as the second catalyst, raise the temperature to 120°C under the protection of an inert gas, react for 20 hours, and then cool to room temperature to obtain a solid product, which is Bio-based polyester diol A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com