Environment-friendly plastic packaging bag and processing method thereof

A packaging bag and environment-friendly technology, which is applied in the field of environment-friendly plastic packaging bags and their processing, can solve the problems that the mechanical quality and degradability of degradable packaging plastic bags cannot meet the needs of use, and achieve great market competitiveness and Economic benefits of production, simple preparation method, and the effect of ensuring weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] An environment-friendly plastic packaging bag, each component and its corresponding parts by weight are shown in Table 1 below:

[0037] Table 1

[0038] components parts by weight Linear Low Density Polyethylene 80 PVC 10 EPI 1 corn starch 15 Modified soybean starch 5 Modified montmorillonite powder 4 Calcium stearate 1 Epoxidized soybean oil 3 ferrocene 0.2 Antioxidants 0.1 polyethylene wax 5 Chitosan 1 polylactic acid 2

[0039] The preparation method of modified soybean starch comprises the steps:

[0040] 1) First mix soybean starch, sodium pyrophosphate, tetraethyl titanate, linoleic acid, and disodium ethylenediaminetetraacetate into a mixing tank, stir evenly and set aside;

[0041] 2) The mixing material obtained in step 1) is put into a high-speed mixer together, heated and stirred at a high speed, and taken out after 25 to 30 minutes to obtain the modified soybean st...

Embodiment 2

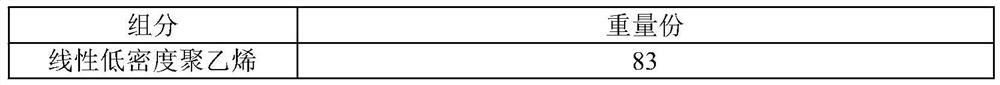

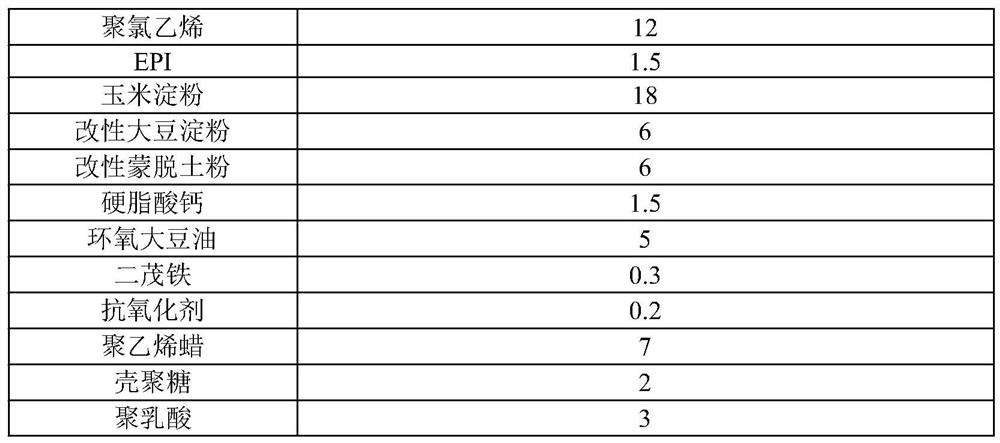

[0057] An environment-friendly plastic packaging bag, each component and its corresponding parts by weight are shown in Table 2 below:

[0058] Table 2

[0059]

[0060]

[0061] The preparation method of modified soybean starch comprises the steps:

[0062] 1) First mix soybean starch, sodium pyrophosphate, tetraethyl titanate, linoleic acid, and disodium ethylenediaminetetraacetate into a mixing tank, stir evenly and set aside;

[0063] 2) Put the mixing material obtained in step 1) into a high-speed mixer, heat and stir at a high speed, and take it out after 28 minutes to obtain modified soybean starch.

[0064] In step 1), the corresponding weight ratio of soybean starch mixed with sodium pyrophosphate, tetraethyl titanate, linoleic acid and disodium edetate is 93:5:6:2:3.

[0065] The heating and high-speed stirring treatment operation in step 2) is specifically: heating the high-speed mixer to keep the internal temperature at 137° C., and then performing stirring...

Embodiment 3

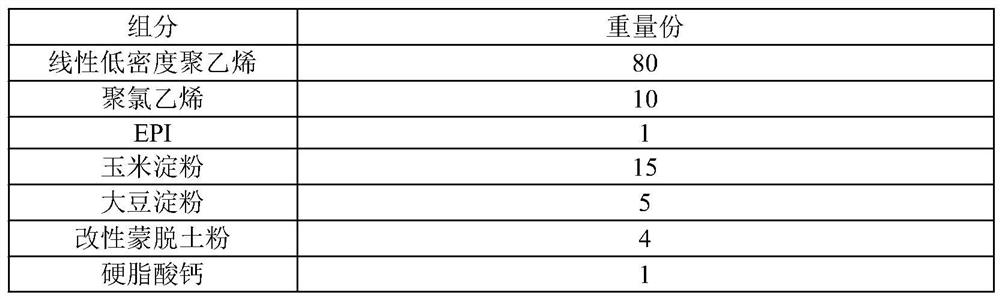

[0079] An environment-friendly plastic packaging bag, each component and its corresponding parts by weight are shown in Table 3 below:

[0080] table 3

[0081] components parts by weight Linear Low Density Polyethylene 85 PVC 15 EPI 2 corn starch 20 Modified soybean starch 7 Modified montmorillonite powder 8 Calcium stearate 2 Epoxidized soybean oil 6 ferrocene 0.4 Antioxidants 0.3 polyethylene wax 8 Chitosan 3 polylactic acid 5

[0082] The preparation method of modified soybean starch comprises the steps:

[0083] 1) First mix soybean starch, sodium pyrophosphate, tetraethyl titanate, linoleic acid, and disodium ethylenediaminetetraacetate into a mixing tank, stir evenly and set aside;

[0084] 2) Put the stirring material obtained in step 1) into a high-speed mixer, heat and stir at a high speed, and take it out after 30 minutes to obtain modified soybean starch.

[0085] In step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com