Probiotic microcapsule preparation based on water-in-water emulsion structure and preparation method thereof

A technology of water-in-water emulsion and probiotics, which is applied in the direction of microcapsule preparation, microsphere preparation, lactobacillus, etc., can solve the problems of preventing water transmission, not being able to dry directly, preventing the diffusion of nutrients and metabolites, etc., to increase the load Quantity, good for diffusion, wide range of emulsification temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

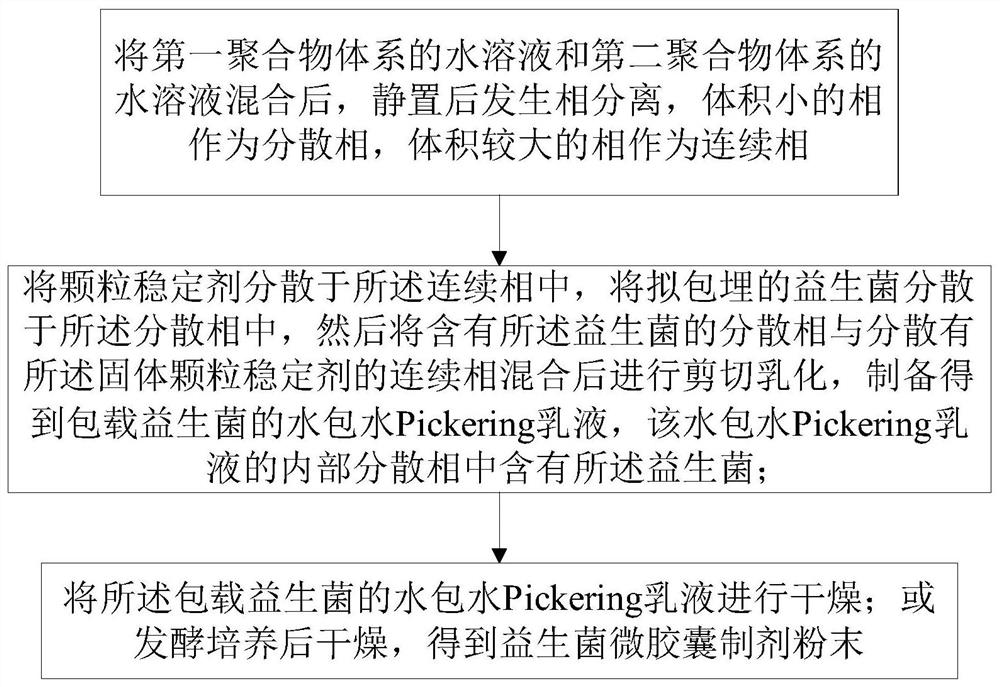

[0050] A kind of preparation method of the probiotic microcapsule preparation based on the water-in-water emulsion structure that the present invention proposes, such as figure 1 shown, including the following steps:

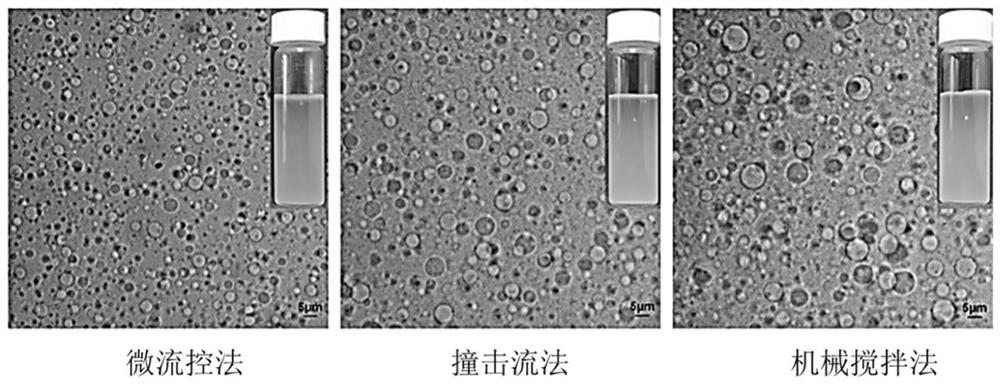

[0051] (1) After mixing the aqueous solution of the first polymer system and the aqueous solution of the second polymer system, the polymer in the first polymer system and the polymer in the second polymer system have a water holding capacity of water Different capacities lead to different distribution ratios of water in the two polymer systems, that is, the water in the polymer system with weak water holding capacity will migrate to the polymer system with strong water holding capacity; standing still to separate the phases, resulting in different volumes Two phases, wherein the bulky phase is used as the continuous phase, and the small volume phase is used as the dispersed phase; the first polymer system contains one or more water-soluble polymers, and the sec...

Embodiment 1

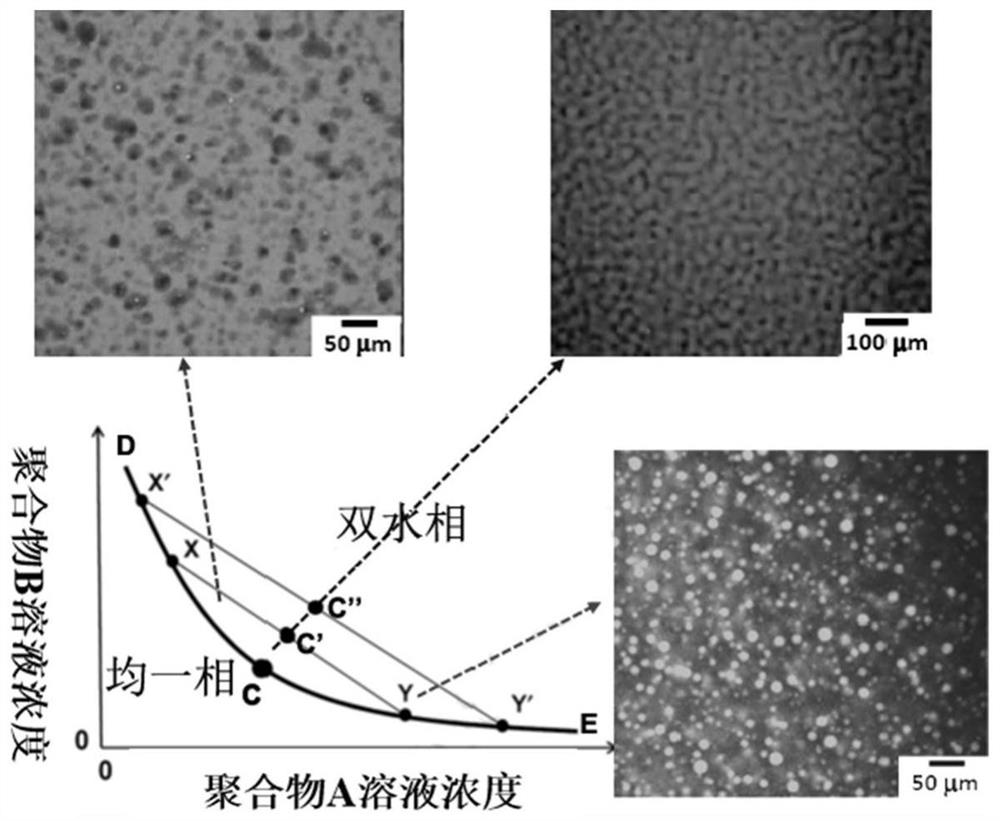

[0094] Take by weighing 3 grams of dextran (molecular weight is 500000Da, solubility parameter is 23.1 (Cal / cm 3 ) 0.5 ), and 5 grams of polyethylene glycol (molecular weight is 88000Da, solubility parameter is 9.38 (Cal / cm 3 ) 0.5 ), were dissolved in 100 grams of pure water to prepare respectively 3% dextran aqueous solution A (Zeta potential is -11mV) and 5% polyethylene glycol aqueous solution B (Zeta potential is -17mV) in 100 grams of pure water. According to the mass ratio of the dextran aqueous solution and the polyethylene glycol aqueous solution being 1:1, the above-mentioned solutions were mixed, and after standing, the phases were separated. The water in the polyethylene glycol system will migrate to the dextran system, and the concentration of the two will change. At this time, according to the concentration of the two phases after mixing and the phase diagram, it is determined that the dispersed phase is a polyethylene glycol-rich phase, and the continuous pha...

Embodiment 2

[0096] Take by weighing 3 grams of dextran (molecular weight is 500000Da, solubility parameter is 23.1 (Cal / cm 3 ) 0.5 ) and 10 grams of polyethylene glycol (molecular weight is 88000Da, solubility parameter is 9.38 (Cal / cm 3 ) 0.5) and, the preparation mass fraction is 3% dextran aqueous solution A (Zeta potential is-11mV) and mass fraction is 10% polyethylene glycol aqueous solution B (Zeta potential is-18mV), according to dextran aqueous solution and polyethylene glycol The mass ratio of the diol aqueous solution is 1:4, and the above solutions are mixed, and after standing, the phases are separated. The water in the polyethylene glycol system will migrate to the dextran system, and the concentration of the two will change. At this time, according to the concentration of the two phases after mixing and the phase diagram, it is determined that the dispersed phase is a polyethylene glycol-rich phase, and the continuous phase is a dextran-rich phase. The added mass fractio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com