Perovskite solar cell device based on polyvinyl acetate passivation film surface/interface defects and preparation method thereof

A polyvinyl acetate, solar cell technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, electrical components, etc., can solve problems such as carrier non-radiative conformity loss, and achieve stability problems, preparation and passivation. The chemical method is simple and easy to implement, and the effect of excellent photoelectric conversion characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] SnO 2 The preparation method of the electron transport layer: the SnO 2 Mix the nanoparticle solution with high-purity water at a volume ratio of 1:3, and stir for 10 minutes at room temperature to obtain transparent and uniform SnO 2 solution.

[0030] The preparation method of perovskite precursor liquid: step 1, at first the PbI that quality is 691.5mg 2 Add it to a mixed solvent of DMF and DMSO with a volume ratio of 900-940:60-100 μL to dissolve, and stir at 120-150° C. for 0.3-0.5 h to obtain a precursor solution 1; Step 2: Mix 271.5 mg HC (NH 2 ) 2 I(FAI), 19.5mg CH 3 NH 3 I(MAI) and 27.3mgCH 3 NH 3 Dissolve Cl(MACl) in 3mL of isopropanol to obtain a mixed organic salt solution, and stir at room temperature for 0.3-0.5h to obtain precursor solution 2.

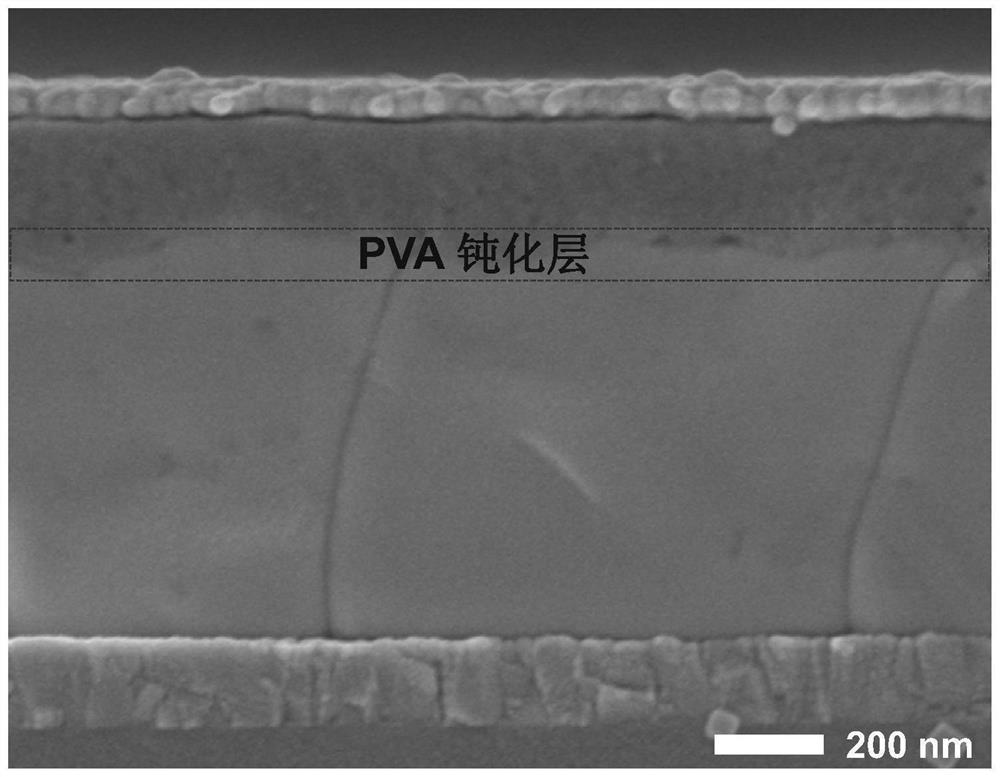

[0031] The preparation method of the PVA passivation layer: Dissolve PVA in high-purity chlorobenzene to obtain a chlorobenzene solution with a PVA concentration of 5mg / 1mL, stir at 80°C for 24h, and stand...

Embodiment 2

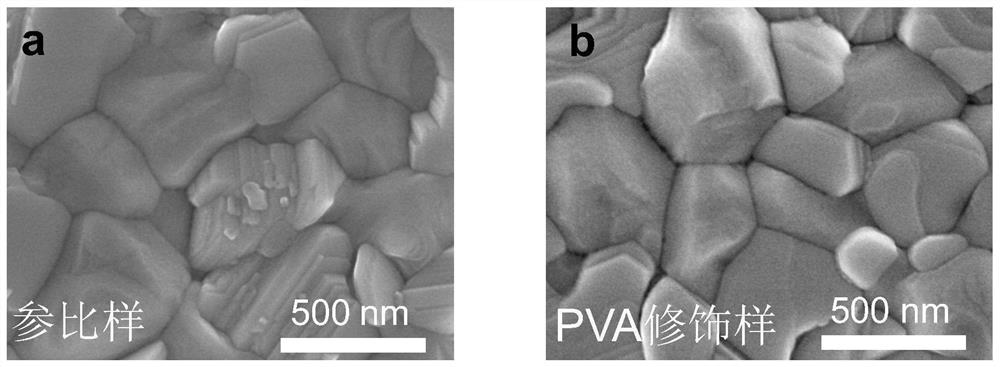

[0035] This embodiment discloses a perovskite solar cell device based on PVA passivation film surface / interface defects, and its preparation steps are as follows:

[0036] The substrate is made of conductive ITO grown on glass. Adopt the SnO that embodiment 1 prepares 2 solution, perovskite precursor, PVA solution and Spiro-OMeTAD solution.

[0037] (1) Before preparing the electron transport layer, first clean the substrate, the substrate is 15×15mm 2 square glass, one side of the glass is coated with 7.5×15mm 2 The ITO. Ultrasonic cleaning was performed for 30 min with detergent, deionized water, ethanol, and isopropanol, respectively. Washed substrate with N 2 Dry it with an air gun and put it into a watch glass, treat it with UV-ozone cleaning equipment for 12 minutes, and store it in a dust-free environment for later use.

[0038] (2) Prepare SnO by single-step spin-coating process 2 electron transport layer. That is, turn on the spin coater, set it at 3000 rpm fo...

Embodiment 3

[0045] This embodiment discloses a perovskite solar cell device based on PVA passivation film surface / interface defects, and its preparation steps are as follows:

[0046] The substrate is made of conductive ITO grown on glass. Adopt the SnO that embodiment 1 prepares 2 solution, perovskite precursor, PVA solution and Spiro-OMeTAD solution.

[0047] (1) Before preparing the electron transport layer, first clean the substrate, the substrate is 15×15mm 2 square glass, one side of the glass is coated with 7.5×15mm 2 The ITO. Ultrasonic cleaning was performed for 30 min with detergent, deionized water, ethanol, and isopropanol, respectively. Washed substrate with N 2 Dry it with an air gun and put it into a watch glass, treat it with UV-ozone cleaning equipment for 12 minutes, and store it in a dust-free environment for later use.

[0048] (2) Prepare SnO by single-step spin-coating process 2 electron transport layer. That is, turn on the spin coater, set it at 3000 rpm fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com