Single-wafer-type radio frequency plasma glue sweeping equipment

A radio-frequency plasma and monolithic technology, which is applied in the manufacture of discharge tubes, electrical components, semiconductors/solid-state devices, etc., can solve problems such as poor deglue effect, simple structure, and single function, and achieve damage avoidance, reasonable design, and easy operation. Simple and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

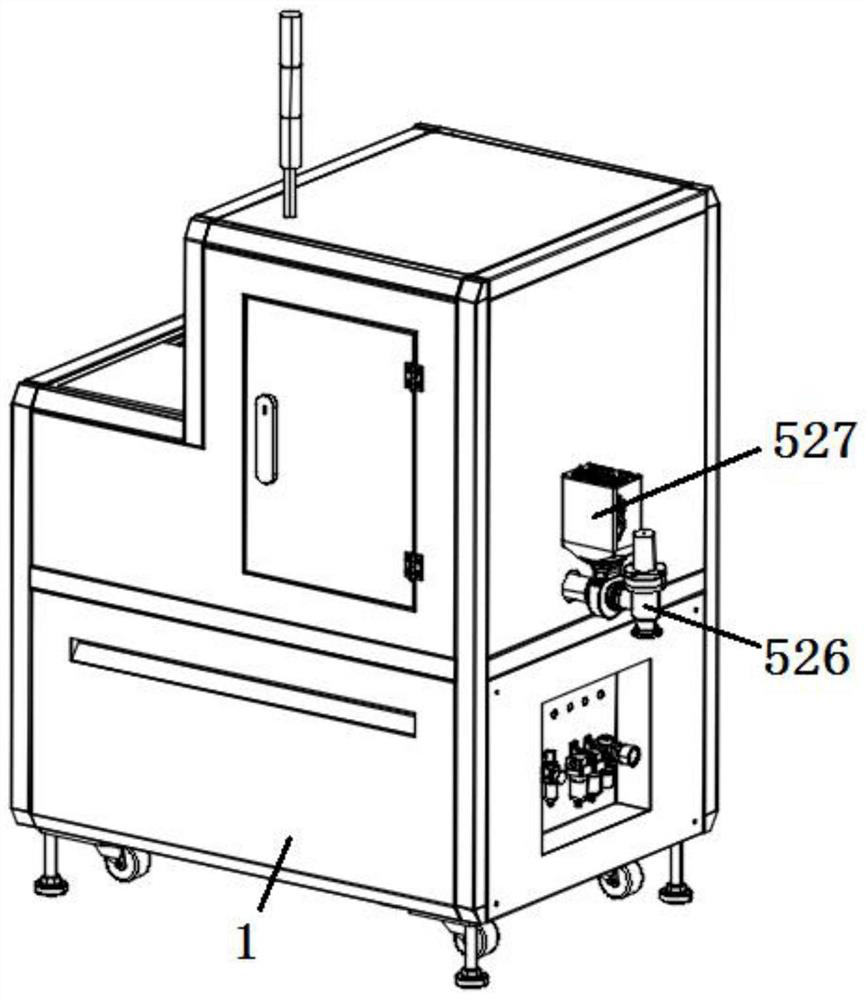

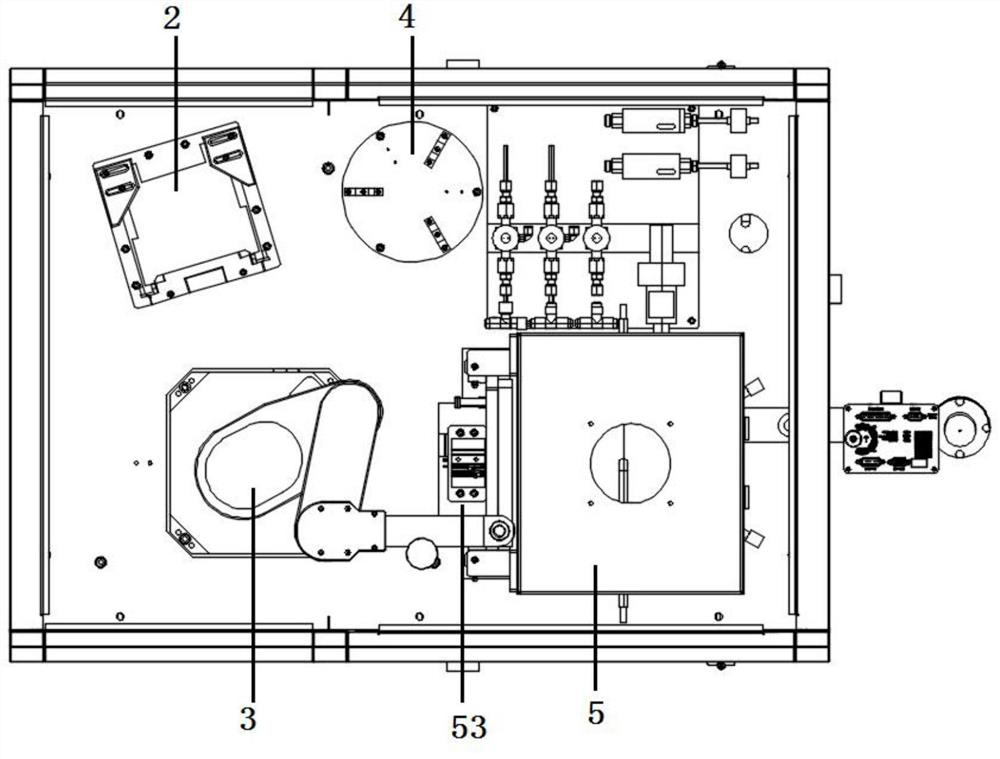

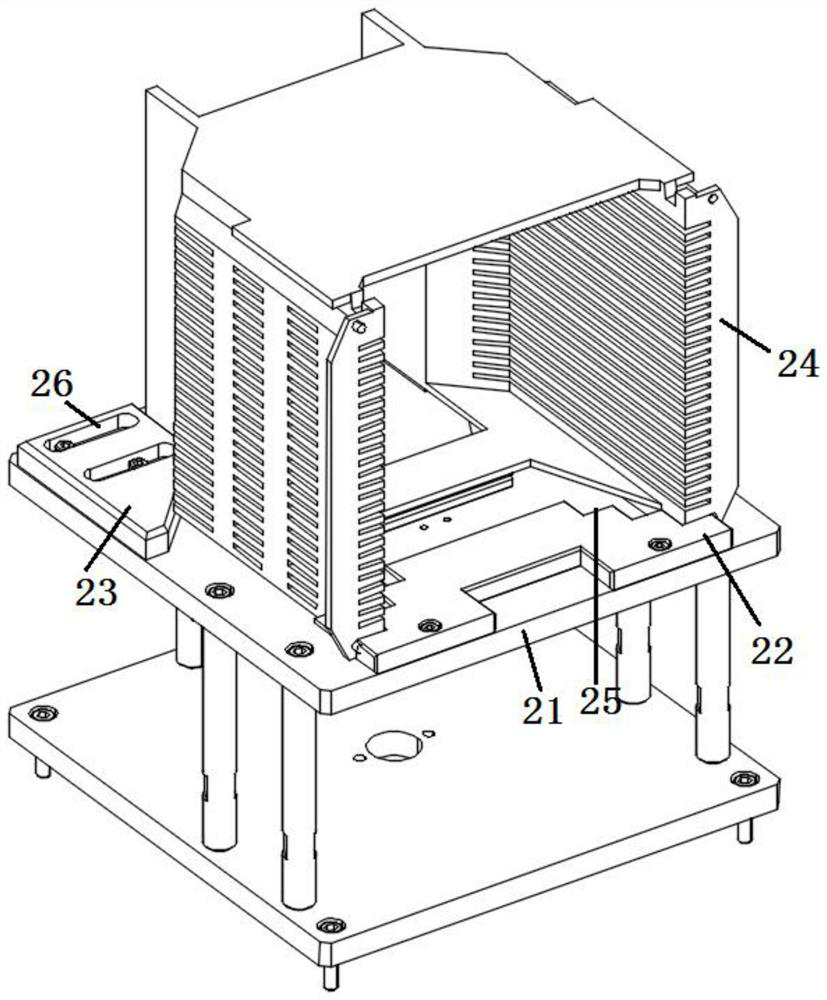

[0044] see Figure 1~14 As shown, this embodiment specifically discloses and provides a technical solution for a single-chip radio-frequency plasma glue sweeping device, including a device main body 1, and the device main body 1 mainly includes a cassette placement mechanism 2, a wafer handling robot 3, and a wafer calibration mechanism 4 and vacuum reaction chamber system 5;

[0045] The working process of the glue sweeping equipment is as follows:

[0046] First, place the cassette 24 containing the wafers on the cassette placement mechanism 2, and the wafer handling robot 3 will take out the wafers by vacuum suction, transport them to the wafer calibration mechanism 4 to release the vacuum for calibration, and at the same time control the automatic opening and closing of the door The mechanism 53 opens the door, and the calibrated wafer is taken out by vacuum adsorption by the wafer handling robot 3, and put into the reaction chamber of the vacuum reaction chamber system 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com