Phosphorus-free nitrogen-free semiconductor packaging cleaning agent

A semiconductor and cleaning agent technology, applied in the field of cleaning agents, can solve problems such as human fertility hazards and environmental pollution, achieve optimal cleaning effects, avoid environmental pollution, and be environmentally friendly cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

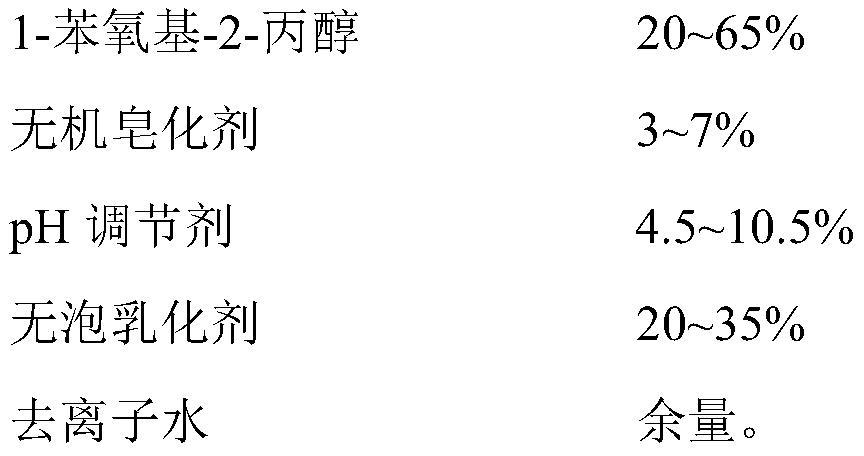

[0025] The phosphorus-free and nitrogen-free semiconductor encapsulation cleaning agent of the present embodiment comprises the raw material of following weight percent:

[0026]

Embodiment 2

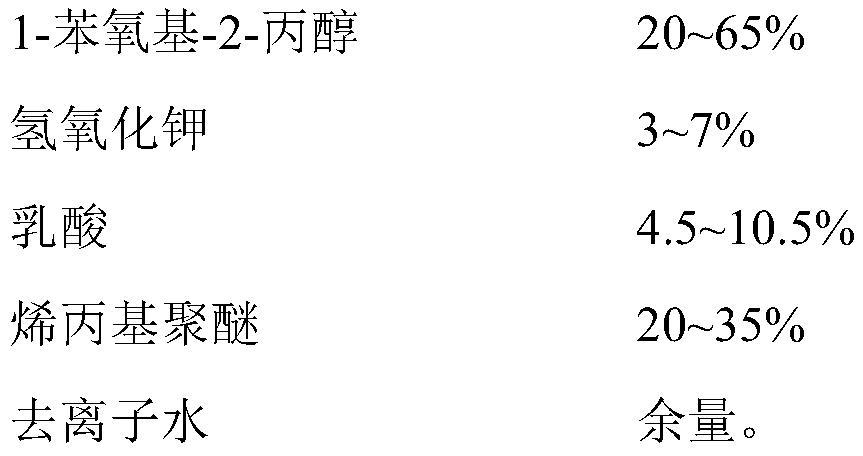

[0028] The phosphorus-free and nitrogen-free semiconductor encapsulation cleaning agent of the present embodiment comprises the raw material of following weight percent:

[0029]

Embodiment 3

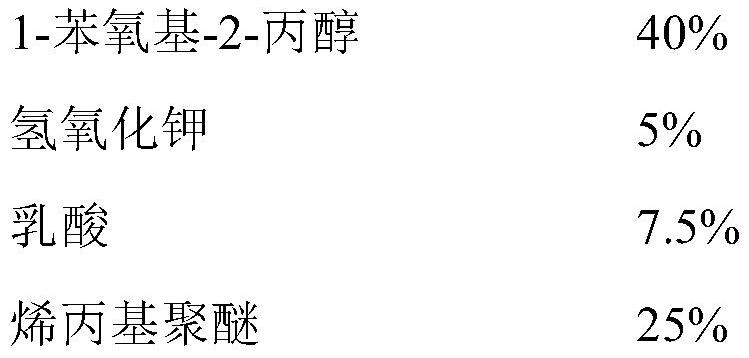

[0031] The phosphorus-free and nitrogen-free semiconductor encapsulation cleaning agent of the present embodiment comprises the raw material of following weight percent:

[0032]

[0033] The preparation method of the non-phosphorous and nitrogen-free semiconductor packaging cleaning agent of Examples 1-3 is to weigh each component according to the formula amount and mix them evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com