Surface grinding and derusting device for metal building materials

A technology for the surface of building materials and metal sheets, which is applied in the direction of grinding/polishing safety devices, metal processing equipment, grinding machines, etc. It can solve the problems that the rust remover and debris mixture cannot be discharged quickly, and the energy consumption is large, so as to achieve good grinding The effects of rust removal, accelerated discharge rate, and accelerated filtration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

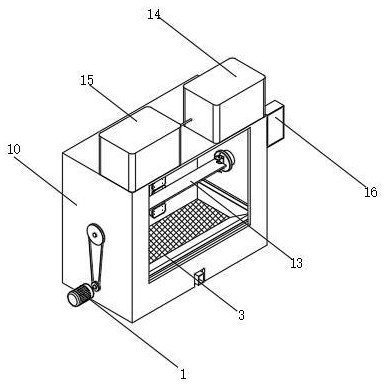

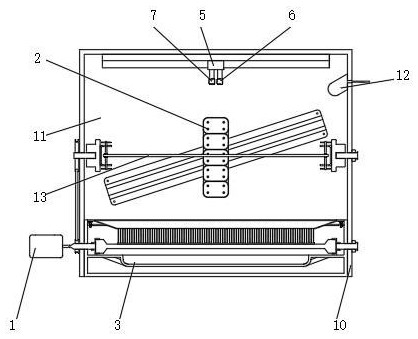

[0036] Such as figure 1 , 2 , 3, 4, 6, 8, and 9, a metal building material surface grinding and derusting device includes a box body 10, an operating warehouse 11, a detection head 12, a driving device 1, a metal plate 13 and a metal pipe 17, and the box body The inside of 10 is provided with an operating compartment 11, and the upper part of the operating compartment 11 is provided with a driving device 1. The driving device 1 includes a second connector 104, a third connector 105 and a clamping piece 106. One side of the box body 10 is provided with There is a second connector 104, the other side of the box body 10 is provided with a third connector 105, the third connector 105 and the second connector 104 are placed on the end face of the operation compartment 11 and a clamping piece 106 is provided, and the operation compartment 11 The two inner clamping parts 106 clamp the metal plate 13;

[0037]The driving device 1 also includes a first connector 101, a stepper motor ...

Embodiment 2

[0041] Such as Figure 4 , 6 , 7 and 8, a grinding and derusting mechanism of a metal building material surface grinding and derusting device, the grinding and derusting mechanism 2 includes a first slide rail 201, a linear drive 202, a first grinding piece 203, a second grinding piece 204, The 3rd grinding piece 205, the 4th grinding piece 206 and the 5th grinding piece 207, the storehouse inner rear side of the operation storehouse 11 is provided with the first slide rail 201, and the movable part of the first slide rail 201 is connected with the linear driver 202, and the linear driver The end of 202 is provided with a substrate, and the front end of the substrate is sequentially provided with a first polishing sheet 203, a second polishing sheet 204, a third polishing sheet 205, a fourth polishing sheet 206 and a fifth polishing sheet 207;

[0042] The grinding meshes of the first polishing sheet 203, the second polishing sheet 204, the third polishing sheet 205, the four...

Embodiment 3

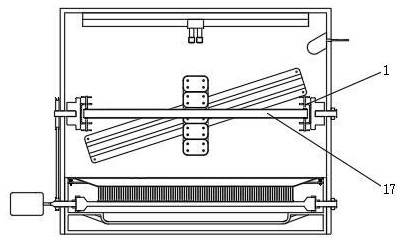

[0044] Such as Figure 5 Shown, a kind of enhanced vibrating type waste collecting device of metal building material surface grinding derusting device, vibrating type waste collecting device 3 also comprises fixed frame 306, spring 307, special-shaped frame 308 and filter film 309, and the box of collection box 301 The upper part is provided with a fixed frame 306, the four corners of the upper end of the fixed frame 306 are provided with springs 307, the upper part of the collection box 301 is provided with a special-shaped frame 308, the special-shaped frame 308 is connected with the spring 307, and the bottom of the special-shaped frame 308 is provided with a filter. Membrane 309;

[0045] The special-shaped frame 308 and the collection box 301 are movable, the collection box 301 is fixedly connected with the fixed frame 306, the filter film 309 is fixedly connected with the special-shaped frame 308, the cleaning brush 305 rotates and contacts the lower end of the filter fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com