A circuit board edging device with self-turning function and using method thereof

A circuit board, self-turning technology, applied in the direction of grinding/polishing safety device, printed circuit, printed circuit manufacturing, etc. The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

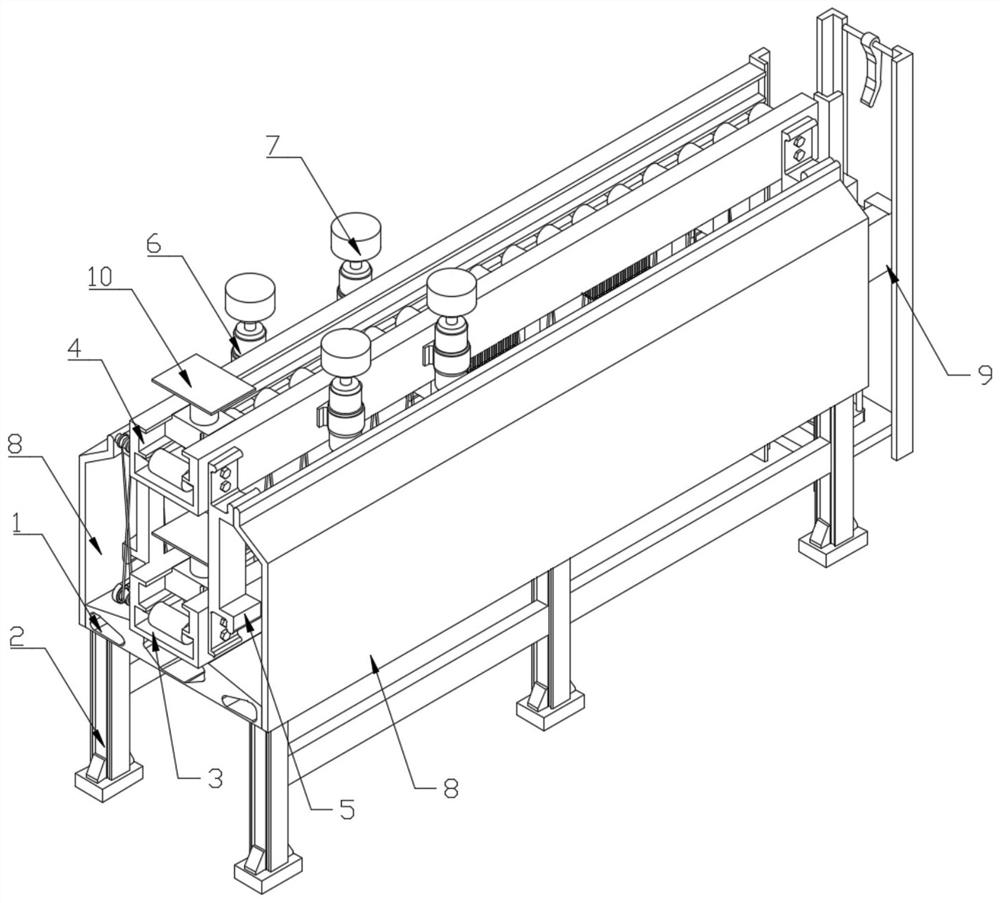

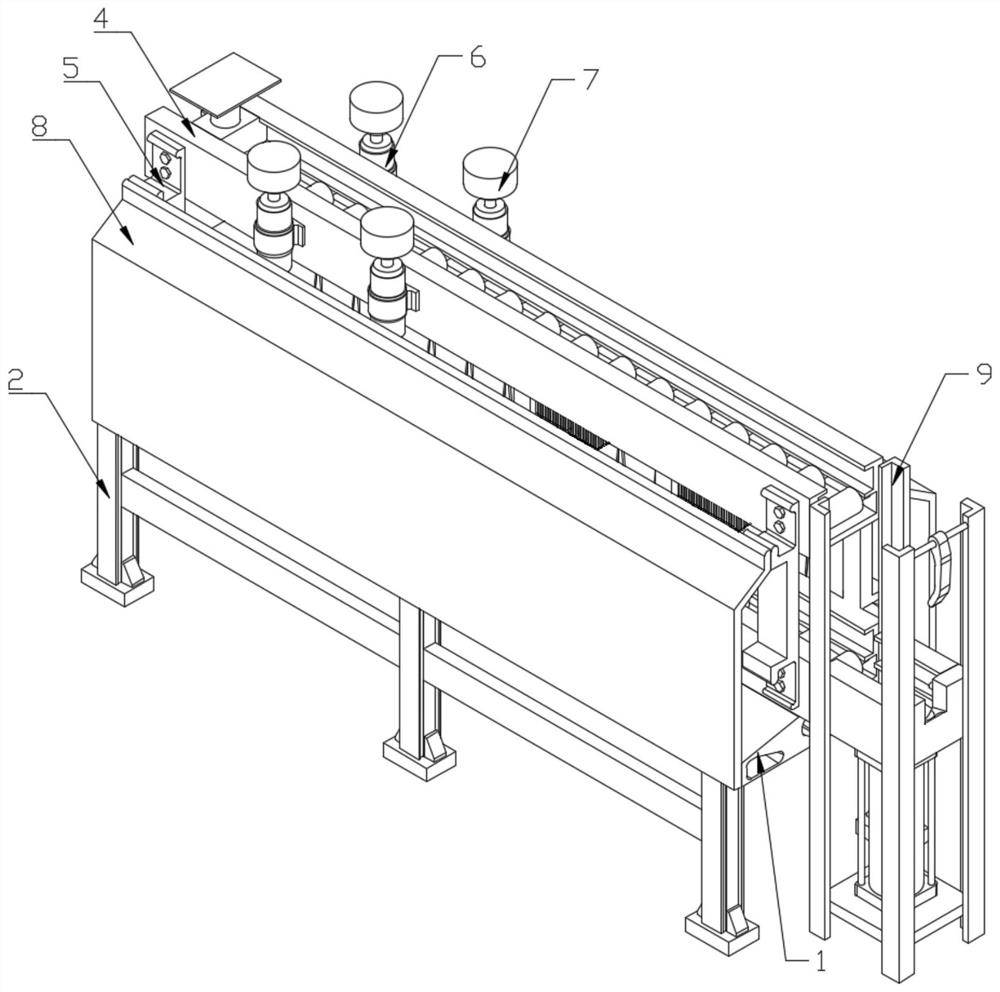

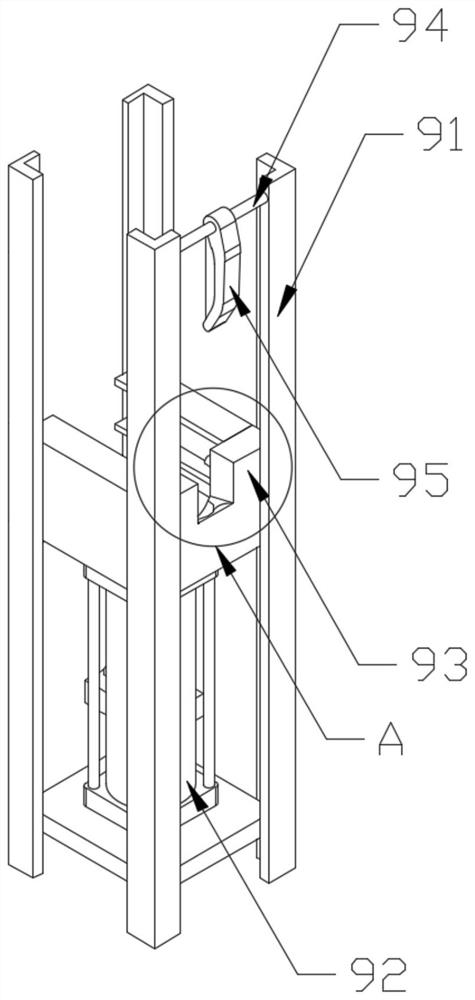

[0040] Attached below Figure 1-8 The present invention is further described with examples:

[0041]A circuit board edging device with a self-turning function, comprising a rack table 1, two rows of legs 2 are fixedly installed on both sides of the bottom of the rack table 1, and three legs 2 are used in each row. , and are fixedly connected by cross braces; the top of the rack table 1 is fixedly installed with a lower transmission track 3 that facilitates the transportation of the circuit board turning assembly 16; the upper transmission track 4 is provided above the lower transmission track 3, and The two sides of the lower transmission rail 3 and the upper transmission rail 4 are fixedly installed by a plurality of side mounting frames 5; the two sides of the lower transmission rail 3 and the upper transmission rail 4 are also provided with protective casings 8; the protective casing 8 It is fixedly connected to the mounting frame 5 and the rack table 1 through bolts;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com