Combined type centering edge grinding machine

A kind of edging machine and composite technology, which is applied in the direction of machine tools suitable for grinding workpiece edges, parts of grinding machine tools, grinding machines, etc., can solve the problems of poor centering accuracy, achieve low cost, strong operability, and simplify Institutional Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

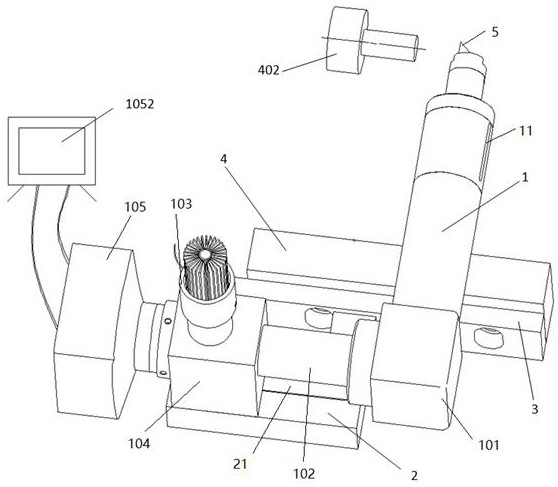

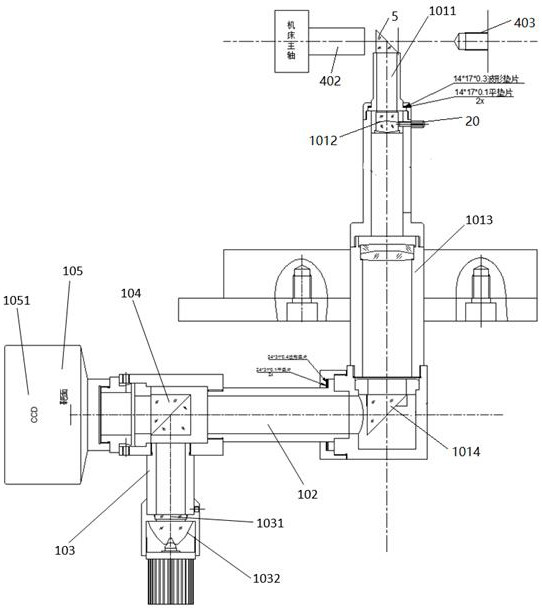

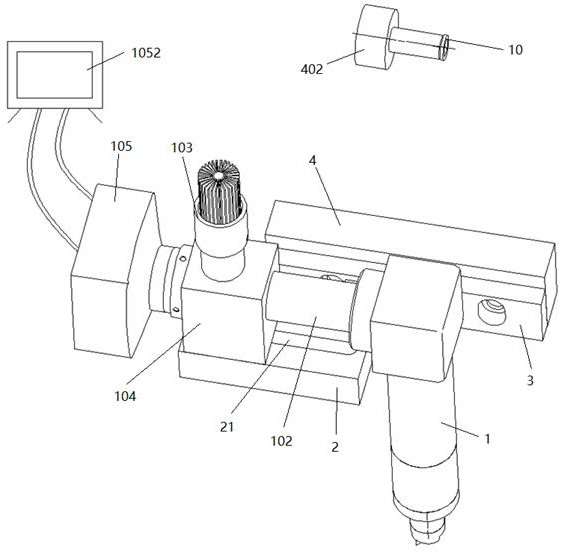

[0037] Refer to attached Figure 1-8 As shown in a compound centering edger, the mechanical centering edger 4 has a symmetrical main shaft that can hold a lens. Specifically, the main shaft includes a first main shaft that provides rotational drive (in the figure shown in 402) and the second main shaft (shown in 402 among the figures) for clamping the lens, and the end of the first main shaft is provided with a vacuum suction device (including a rotary air valve and a suction plate for absorbing the lens, not shown in the figure ). The lens is adsorbed on the first spindle 402 by a vacuum suction device, and pressed against the other side of the lens by the second spindle 403 , and the lens is driven to rotate by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com