PIM-1-based mixed matrix membrane and preparation method thereof

A PIM-1, mixed matrix membrane technology, applied in the field of membrane materials, can solve problems such as slow recovery and duration of myocardial damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

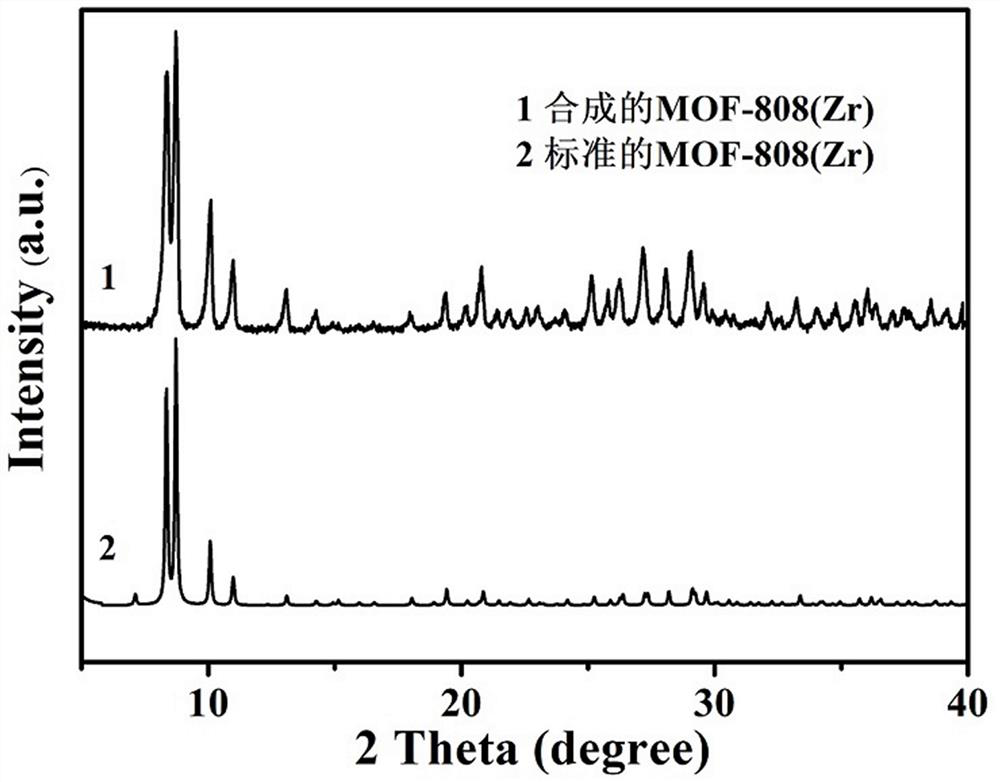

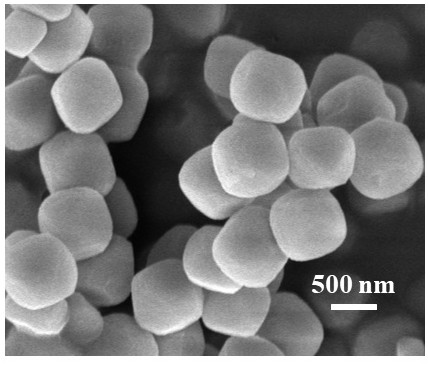

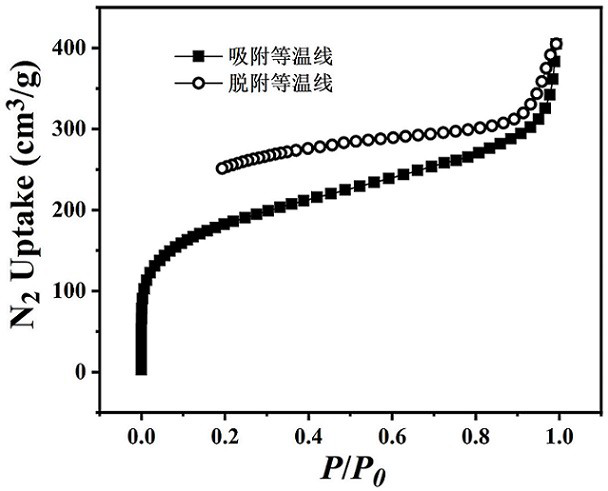

[0047] (1) The preparation process of a mixed matrix membrane based on PIM-1 in this example: first, accurately weigh Zr°Cl2 8H2O (1.93 g) into a round bottom flask with a magnetic stirring bar, add deionized Water (20 mL), stirring continuously at a constant speed at room temperature until the zirconium oxychloride octahydrate is completely dissolved. Accurately weigh trimesic acid (0.42 g) into a round bottom flask, stir and sonicate for 30 min until completely dissolved. Accurately weigh acetic acid (20 mL) and concentrated hydrochloric acid (200 μL), and add them dropwise into the round bottom flask while stirring. Connect the round-bottomed flask to the condensing reflux tube, and connect the top of the condensing tube to a balloon to ensure a constant pressure in the reactor. Place the round-bottomed flask in an oil bath, keep stirring at 110°C, and react for 20 h. After the reaction was completed, it was cooled to room temperature, and the solid product was collected b...

Embodiment 2

[0056] (1) The preparation process of a mixed matrix membrane based on PIM-1 in this example: first, accurately weigh zirconium oxychloride octahydrate (1.93 g) into a round bottom flask with a magnetic stirring bar, add deionized Water (20 mL), stirring continuously at a constant speed at room temperature until the zirconium oxychloride octahydrate is completely dissolved. Accurately weigh trimesic acid (0.42 g) into a round bottom flask, stir and sonicate for 30 min until completely dissolved. Accurately weigh acetic acid (20 mL) and concentrated hydrochloric acid (200 μL), and add them dropwise into the round bottom flask while stirring. Connect the round-bottom flask to the condensation reflux tube, and connect the top of the condensation tube to a balloon to ensure a constant pressure in the reactor. Place the round-bottom flask in an oil bath, keep stirring at 110 °C, and react for 20 h. After the reaction was completed, it was cooled to room temperature, and the solid ...

Embodiment 3

[0065] (1) Preparation process: First, accurately weigh zirconium oxychloride octahydrate (1.93 g) into a round bottom flask with a magnetic stirring bar, add deionized water (20 mL), and continue stirring at a constant speed at room temperature until chlorine octahydrate Zirconia dissolves completely. Accurately weigh trimesic acid (0.42 g) into a round bottom flask, stir and sonicate for 30 min until completely dissolved. Accurately weigh acetic acid (20 mL) and concentrated hydrochloric acid (200 μL), and add them dropwise into the round bottom flask while stirring. Connect the round-bottom flask to the condensation reflux tube, and connect the top of the condensation tube to a balloon to ensure a constant pressure in the reactor. Place the round-bottom flask in an oil bath, keep stirring at 110 °C, and react for 20 h. After the reaction was completed, it was cooled to room temperature, and the solid product was collected by centrifugation. Put the solid precipitate in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com