Dry flue gas desulfurization method of belt conveying horizontal moving bed

A technology of dry flue gas desulfurization and horizontal movement, applied in the field of dry flue gas desulfurization, can solve the problems that it cannot be used around large cities, and the desulfurization efficiency cannot meet environmental protection requirements, and achieves the advantages of improved diffusion, simple operation, and low investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

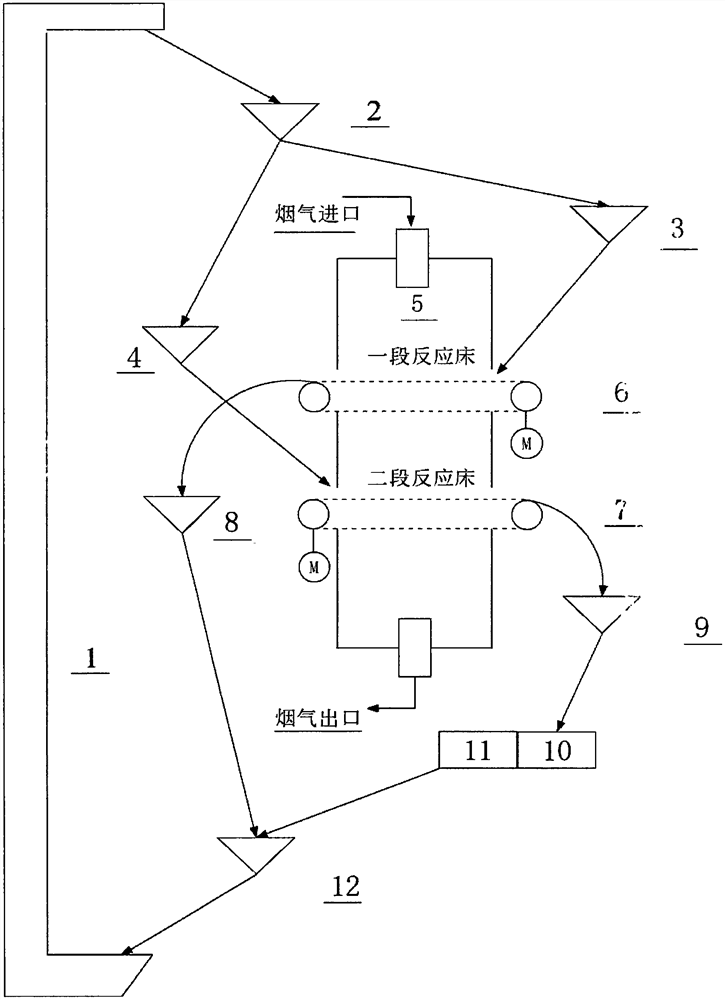

[0053] Two-stage flue gas vertical flow belt conveying horizontal moving bed desulfurization method

[0054] like figure 1 As shown, 1. Expressed as a bucket elevator 2. Expressed as a distribution bin 3. Expressed as a one-stage feed bin 4. Expressed as a two-stage feed bin 5. Expressed as a reactor 6. Expressed as a one-stage belt horizontal conveyor 7. Represented as two-stage belt horizontal conveyor 8. Represented as one-stage discharge bin 9. Represented as two-stage discharge bin 10. Represented as screening machine 11. Represented as mixer 12. Represented as mixing silo.

[0055] The flue gas flows vertically from top to bottom, and the desulfurization method of the horizontal moving bed is to use the surface of the carrier ball to carry 200 mesh Ca(OH)2 powder, and react with sulfur dioxide in the flue gas at 80-200°C to generate sulfuric acid Calcium, to achieve the purpose of desulfurization, after the flue gas enters the reactor (5), it first enters the first stag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com