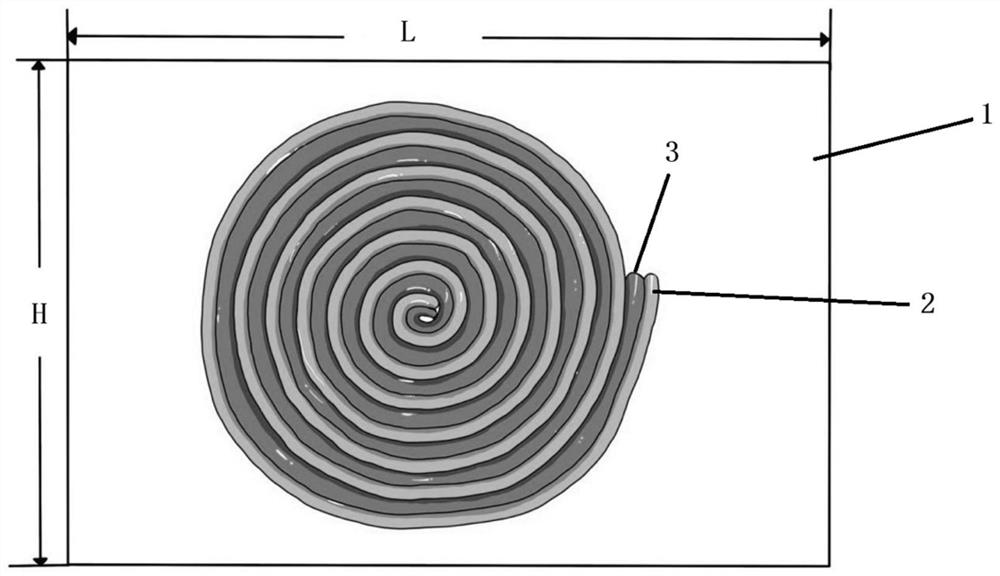

Coil-type alternating automatic inflation and deflation high polymer material gel pad and gel tube thereof

A polymer material, automatic inflation and deflation technology, applied in the field of medical devices, can solve the problems of unstable physical and chemical properties of gel materials, insufficient body pad area, low comfort, etc. Excellent affinity effect, the effect of improving the quality of care

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

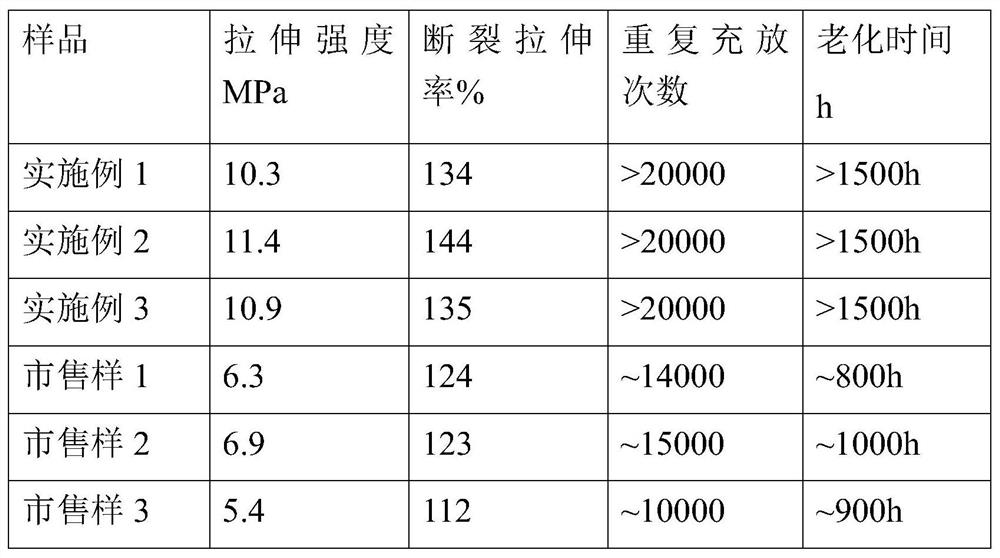

[0054] The inventors of the present application have tested the selection of a large number of materials, and adopted various preparation methods to make A pipe 2 and B pipe 3, and performed performance tests on A pipe 2 and B pipe 3 made by different preparation methods, and finally obtained The optimal preparation method of tube A 2 and tube B 3 is shown, comprising the following steps:

[0055] The first step is to immerse the polished wire into poly N-isopropylacrylamide, N,N'-methylene bisacrylamide, polyoxyethylene methacrylate, methacrylate sulfonate, 2,6-di tert-butyl-p-cresol, potassium persulfate, polyethylene glycol dimethacrylate, polyvinylpyrrolidone, bovine serum albumin and deionized water; maintain the temperature between 7°C and 15°C, and Enter argon for 1 hour to remove the oxygen in the solution; stop feeding the argon for 1 hour, take out the metal wire, isolate the air and age for 2 hours, wrap a layer of gel tube blank on the outside of the wire, and then...

Embodiment 1

[0066] The first step is to immerse the polished wire into poly N-isopropylacrylamide, N,N'-methylene bisacrylamide, polyoxyethylene methacrylate, methacrylate sulfonate, 2,6-di In a solution made of tert-butyl-p-cresol, potassium persulfate, polyethylene glycol dimethacrylate, polyvinylpyrrolidone, bovine serum albumin and deionized water; maintain the temperature between 10°C and pass through argon 1 hour to remove the oxygen in the solution; stop feeding the argon for 1 hour, take out the metal wire, isolate the air and age for 2 hours, wrap a layer of gel tube blank on the outside of the metal wire, and then wrap the gel tube blank The metal wire is immersed in pure water for soaking and cleaning;

[0067] The mass fraction of poly-N-isopropylacrylamide is 15%; the mass fraction of N, N'-methylenebisacrylamide is 5%; the mass fraction of polyoxyethylene methacrylate is 5%; methacrylic acid The mass fraction of sulfonate is 5%; the mass fraction of 2,6-di-tert-butyl-p-cres...

Embodiment 2

[0072] The first step is to immerse the polished wire into poly N-isopropylacrylamide, N,N'-methylene bisacrylamide, polyoxyethylene methacrylate, methacrylate sulfonate, 2,6-di In a solution made of tert-butyl-p-cresol, potassium persulfate, polyethylene glycol dimethacrylate, polyvinylpyrrolidone, bovine serum albumin and deionized water; maintain the temperature between 10°C and pass through argon 1 hour to remove the oxygen in the solution; stop feeding the argon for 1 hour, take out the metal wire, isolate the air and age for 2 hours, wrap a layer of gel tube blank on the outside of the metal wire, and then wrap the gel tube blank The metal wire is immersed in pure water for soaking and cleaning;

[0073] The mass fraction of poly-N-isopropylacrylamide is 10%; the mass fraction of N, N'-methylenebisacrylamide is 5%; the mass fraction of polyoxyethylene methacrylate is 5%; methacrylic acid The mass fraction of sulfonate is 8%; the mass fraction of 2,6-di-tert-butyl-p-cres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com