Environment-friendly latex paint taking ceramic polishing waste residues as regenerated filling and preparation method thereof

An environmentally friendly technology for ceramic polishing waste, applied in latex paint, anti-corrosion coatings, coatings, etc., can solve the problems of difficult increase in processing capacity, low proportion of waste slag application, and small amount of waste slag utilization, and achieve wear resistance and other chemical and Effects of enhanced mechanical properties, resource saving, and reduced particle size dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

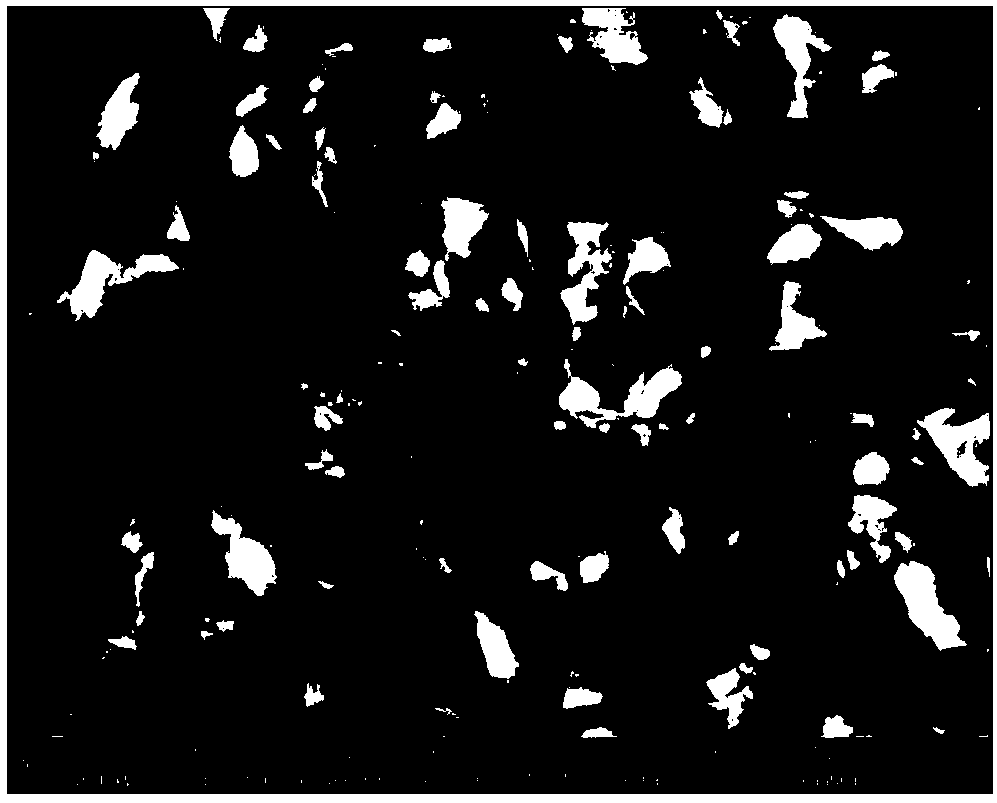

Image

Examples

preparation example Construction

[0030] In the preparation process of latex paint, different additives are added according to actual needs to achieve the required properties. In a preferred embodiment of the present invention, the additives include any one or at least two of thickeners, dispersants, defoamers, anticorrosion and antifungal agents, film-forming aids, leveling agents, and pH regulators.

[0031]As an important additive in latex paint, thickener is mainly used to improve and increase the viscosity of latex paint, maintain a certain rheology, prevent sagging during construction, and endow latex paint with excellent mechanical properties and storage stability. . In the embodiment of the present invention, the thickeners are selected from polyurethane thickeners, alkali-swellable thickeners, and cellulose thickeners, etc., and are added singly or in combination.

[0032] Dispersants reduce the dispersion time of raw materials, stabilize dispersions, reduce flocculation, enhance stability, enhance g...

Embodiment 1

[0045] The present embodiment provides a kind of environment-friendly latex paint with ceramic polishing waste residue as regeneration filler, by weight percentage, comprising:

[0046] Ceramic polishing waste 35%, styrene-acrylic emulsion 25%, rutile titanium dioxide 5%, fluorescent whitening agent 0.1%, propylene glycol 2.2%, alcohol ester film-forming agent 1.3%, hydroxyethyl cellulose 0.1%, anionic dispersant 0.8 %, silicone modified defoamer 0.7%, isothiazolone anticorrosion and antifungal agent 0.2%, alkali swelling thickener 0.5%, silicone modified leveling agent 0.4%, Amp-95pH regulator 0.2%, remaining water.

[0047] It is mainly made by the following methods:

[0048] Weigh the raw materials measured above, add hydroxyethyl cellulose, anionic dispersant, isothiazolone preservative, propylene glycol and 1 / 2 silicone modified defoamer, add 2 / 3 of water, at a speed of 500rpm Mix well for 5 minutes. Subsequently, the ceramic polishing waste slag, rutile titanium dioxi...

Embodiment 2

[0052] The present embodiment provides a kind of environment-friendly latex paint with ceramic polishing waste residue as regeneration filler, by weight percentage, comprising:

[0053] Ceramic polishing waste 20%, styrene-acrylic emulsion 30%, titanium dioxide 3%, ultramarine 0.1%, talcum powder 5%, calcined kaolin 5%, propylene glycol 2.5%, alcohol ester film-forming agent 1.5%, modified hydroxyethyl cellulose 0.1%, 0.7% of non-ionic dispersant, 0.6% of silicone defoamer, 0.2% of isothiazolone anticorrosion and antifungal agent, 0.5% of polyurethane thickener, 0.2% of organic amine pH regulator, and the balance of water.

[0054] It is mainly made by the following methods:

[0055] Weigh the above-measured modified hydroxyethyl cellulose, non-ionic dispersant, isothiazolone anticorrosion and anti-mold agent, propylene glycol and 3 / 4 of the silicone defoamer, add 4 / 5 of the water, at a speed of 400rpm Mix well for 10 minutes. Subsequently, the ceramic polishing waste slag, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com