Automobile front combination lamp sealing structure

A technology of sealing structure and front combination lamp, applied in the field of automotive lighting system, can solve the problems such as the inability to eliminate fogging on the surface of the lamp mask, and achieve the effects of reducing process difficulty, reducing process defects and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

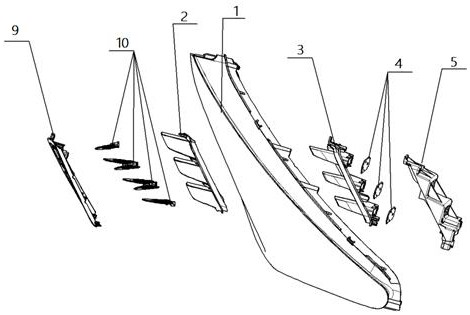

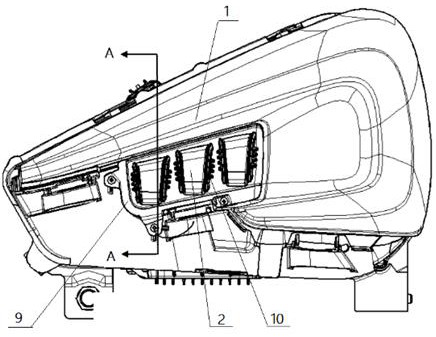

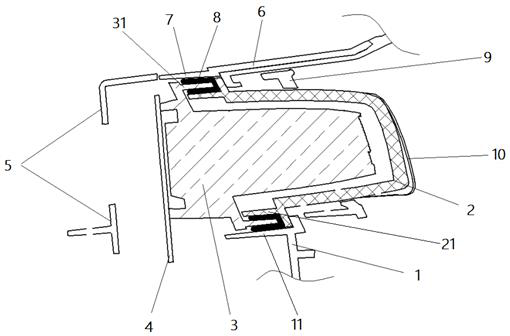

[0026] see figure 1 , figure 2 with image 3 The sealing structure of a kind of automobile front combination lamp shown comprises a headlight mask 1, three small lamp masks 2 arranged in the headlight mask and connected thereto, a light guide plate 3 arranged in each small lamp mask, The circuit board 4 at the rear end of a plurality of light guide plates is characterized in that: the inner side of the headlight mask 1 is provided with an inner clamping part 11, and the rear part of the small lamp mask 2 is provided with an outer clamping part 21; The clamping part 21 is correspondingly clamped with the inner clamping part 11 of the headlight mask 1 to form a "U"-shaped glue groove 7; the glue groove is coated wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com