Surface modified electrode and method for electrolytic treatment of wastewater

A surface modification, electrode technology, applied in the field of cathode electrode preparation, can solve the problems of poor electrode stability and durability, serious electrode corrosion, low energy efficiency, etc., to achieve no danger, enhanced corrosion resistance, service life prolonged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

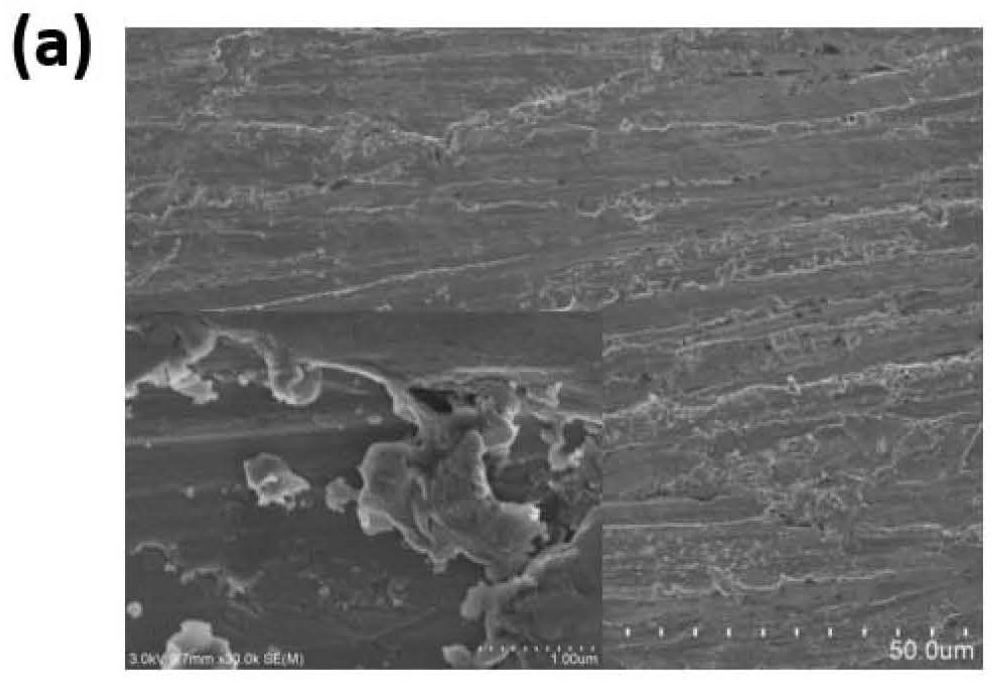

[0058] Embodiment 1: use the iron electrode of tetrapolyphosphoric acid surface modification

[0059] Step 1, prepare treatment solution:

[0060] The concentration of each component in the aqueous solution is: 1.3-3% anhydrous sodium carbonate, 0.5-1.5% sodium hydroxide, 0.8-1.5% sodium silicate, 2.5-4% sodium phosphate; stir and mix evenly to get the preparation treatment liquid.

[0061] Dissolve 3-5g of anhydrous sodium carbonate, 1-3g of sodium hydroxide, 1-4g of sodium silicate, and 4-8g of sodium phosphate in 100-300mL of distilled water in sequence, stir and mix evenly to obtain the prepared treatment solution.

[0062] The reagents selected for use in this embodiment are: soluble sodium salt and sodium hydroxide, only utilizing the higher solubility of sodium salt. The soluble sodium salt can be replaced by an equal concentration of potassium salt. Sodium hydroxide can also be replaced with potassium hydroxide which is similarly alkaline. The impact on subsequent ...

Embodiment 2

[0084] Example 2: Iron cathode material after formic acid surface modification.

[0085] The preparation method of the iron cathode material after formic acid surface modification is as follows:

[0086] Step 1, prepare treatment solution:

[0087] The concentration of each component in the aqueous solution is: 1.3-3% anhydrous sodium carbonate, 0.5-1.5% sodium hydroxide, 0.8-1.5% sodium silicate, 2.5-4% sodium phosphate; stir and mix evenly to get the preparation treatment liquid.

[0088] Dissolve 3-5g of anhydrous sodium carbonate, 1-3g of sodium hydroxide, 1-4g of sodium silicate, and 4-8g of sodium phosphate in 100-300mL of distilled water in sequence, stir and mix evenly to obtain the prepared treatment solution.

[0089] Step 2. Treat the iron pole with electricity

[0090] The iron sheet is used as the working electrode, the platinum sheet is used as the counter electrode, and the treatment liquid prepared in step 1 is used as the electrolyte, and the degreasing is ...

Embodiment 3

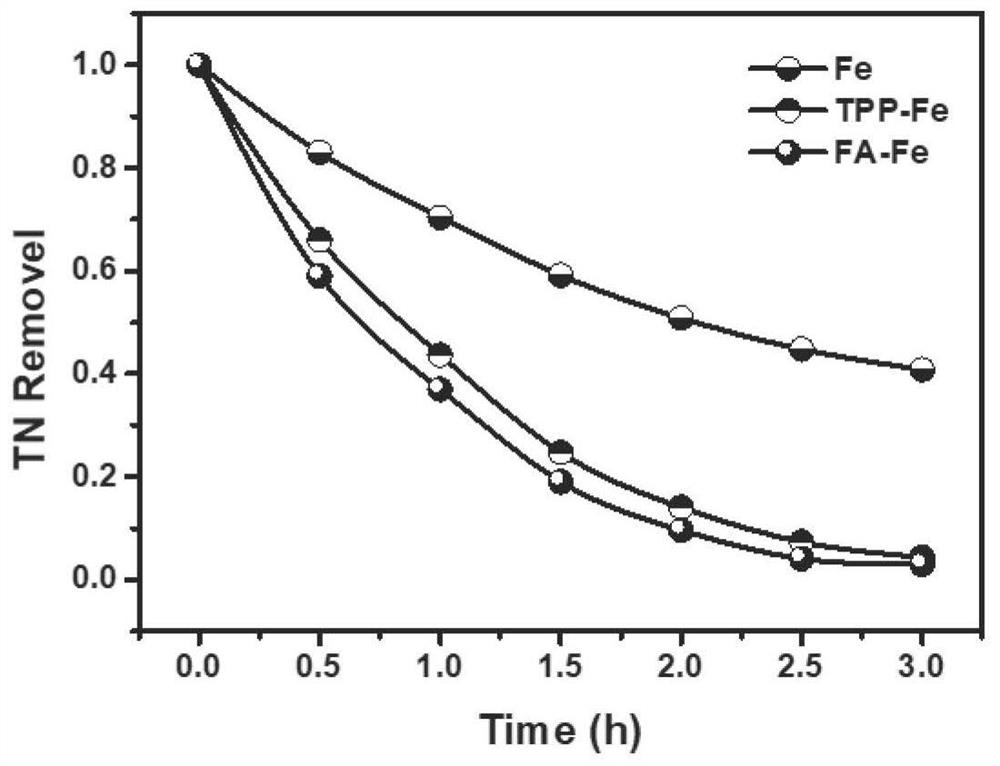

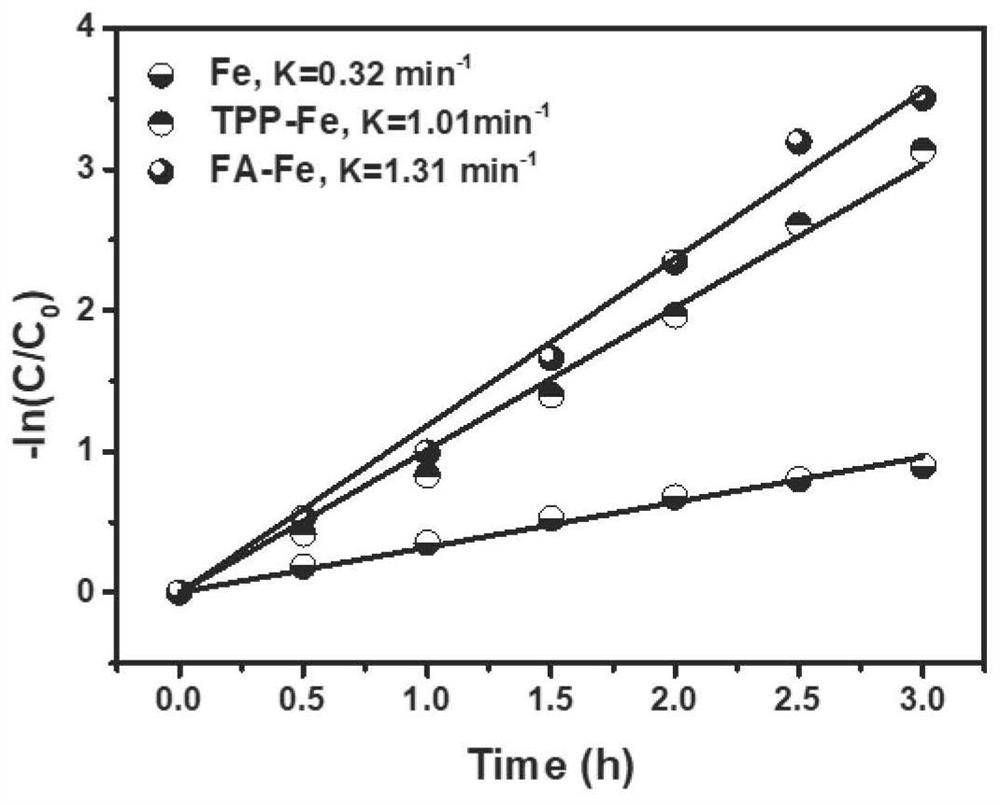

[0105] Example 3: Electrochemical treatment of electroplating wastewater with ruthenium titanium iridium electrode, iron electrode modified by tetrapolyphosphoric acid, and iron electrode modified by formic acid

[0106] The ruthenium titanium iridium electrode is used as the anode, the iron electrode modified by tetrapolyphosphoric acid is used as the cathode, and the iron electrode modified by formic acid is used as the cathode for electrochemical wastewater treatment:

[0107] Inject 7.5L of electroplating wastewater into the electrolytic cell. The initial COD of the electroplating wastewater is about 180mg / L, the total nitrogen is 40-50mg / L, and the ammonia nitrogen is 10mg / L. Set the current density to 5mA / cm 2 Power on and electrolyze for 3 hours.

[0108] The corresponding discharge standards for this wastewater are that COD is lower than 50mg / L, total nitrogen is lower than 15mg / L, and ammonia nitrogen is lower than 5mg / L.

[0109] Such as figure 1 , 2 It is shown ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com