Die assembly for piston manufacturing

A mold and component technology, which is applied in the field of mold components for piston preparation, can solve the problems of high axial requirements for equipment tonnage and difficult molding, and achieve the effects of saving costs, reducing equipment loss, and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is further described and understood by non-limiting examples below.

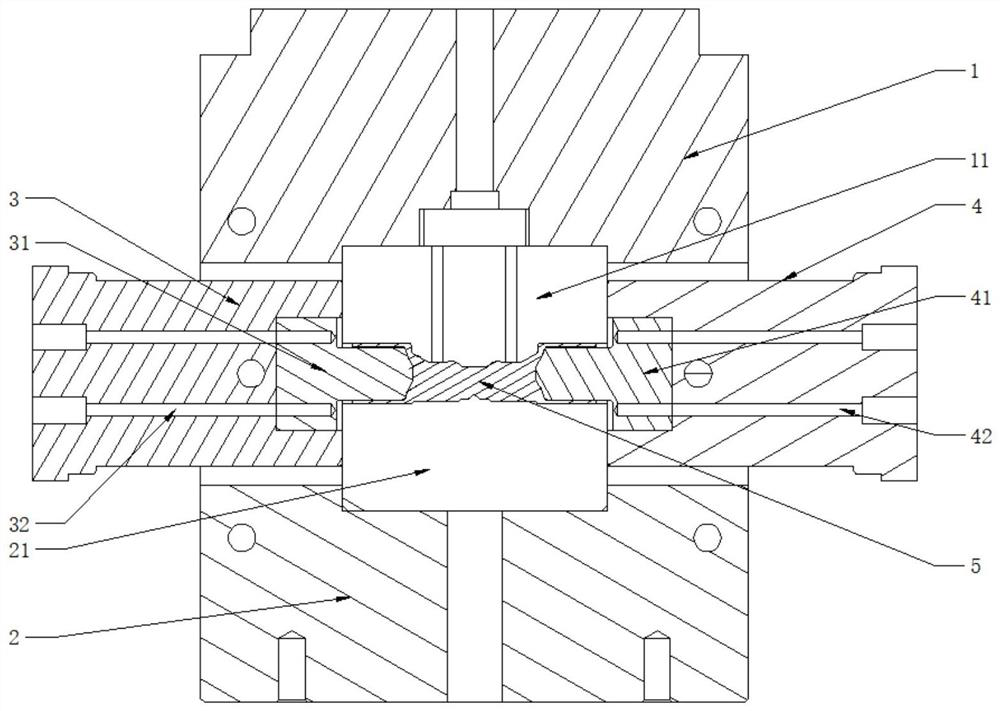

[0011] Such as figure 1 As shown, the present invention provides a mold assembly for piston preparation, comprising an upper die 11, a lower die 21, a left die 3 and a right die 4 that are horizontally arranged on the left and right sides of the lower die 21, fixed on the left die The left punch 31 at the end of 3, the right punch 41 fixed at the end of the right die 4, the upper die 11 is provided with the upper die frame 1 for fixed connection with the power output end of the forging machine, and the lower die 21 The lower part of the piston is fixedly installed on the operating platform 2, and the ends of the left punch 31 and the right punch 41 are arranged facing each other. In order to ensure that the two ends of the piston are concentric, the left punch 31 and the right punch 41 are arranged axis. The left side die 3 is provided with the left side drive channel 32 for dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com