Tobacco shred specification customization system based on long tobacco shred reprocessing

A customized system and reprocessing technology, which is applied in the field of tobacco processing, can solve problems such as difficult filaments and clusters, affecting the quality of cigarettes, and heavy tobacco labor, so as to improve the efficiency of discrimination, improve the quality of cigarettes, and save labor. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

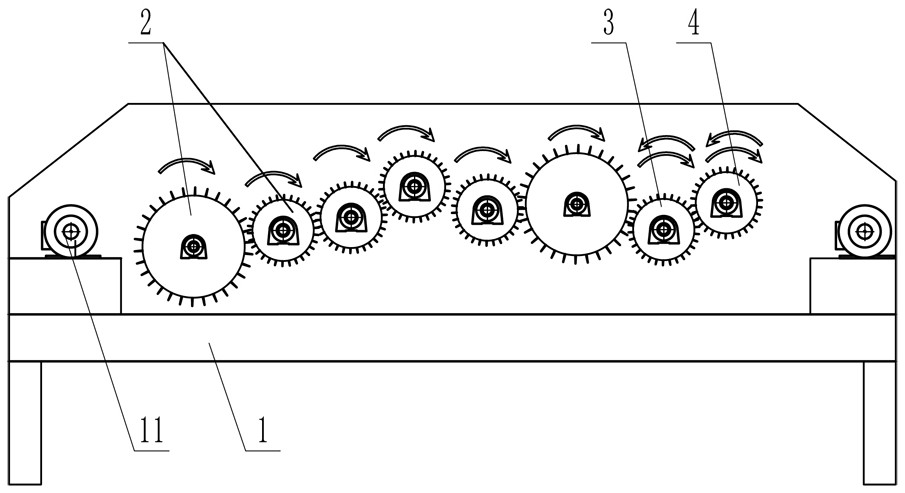

[0031] Such as Figure 1 ~ Figure 2 As shown, a shredded tobacco specification customization system based on the reprocessing of long shredded tobacco includes a frame 1, and also includes a filament sorting device, a filament tearing device and a cluster cutting device arranged on the frame 1;

[0032] The filament sorting device is adjacent to the filament tearing device, and the filament sorting device includes a plurality of needle rollers 1 and 2 sequentially arranged along the forward direction of the shredded tobacco, and the plurality of needle rollers 1 and 2 are arranged in the transmission mechanism. Driven by one and driving mechanism one, they rotate clockwise in the same direction;

[0033] The filament tearing device is adjacent to the filament sorting device, and the filament tearing device includes more than one needle roller 2 3 sequentially arranged along the forward direction of the shredded tobacco, and the needle roller 2 3 is arranged on the transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com