Anti-empty-burning control device

A control device and air-proof burning technology, which is applied in the field of stove air-proof burning, can solve the problems of increasing waste heat and exhaust gas emissions in the kitchen, increasing the risk of kitchen fires, and weak awareness of energy conservation, etc., to achieve easy maintenance and repair, realize air-proof burning control, and reliable storage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] For ease of understanding, combined here Figure 1-4 , the concrete structure and working mode of the present invention are further described as follows:

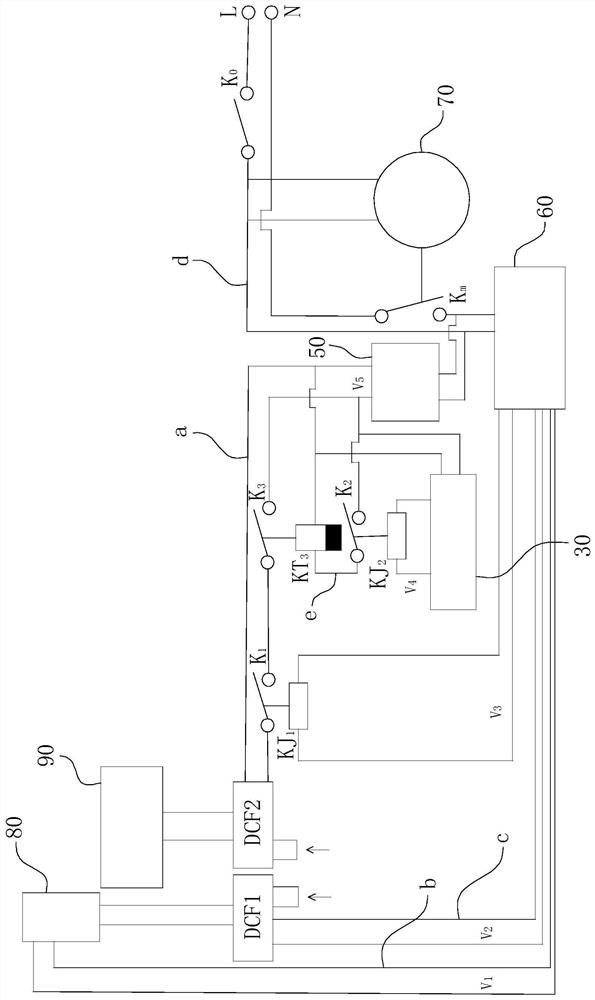

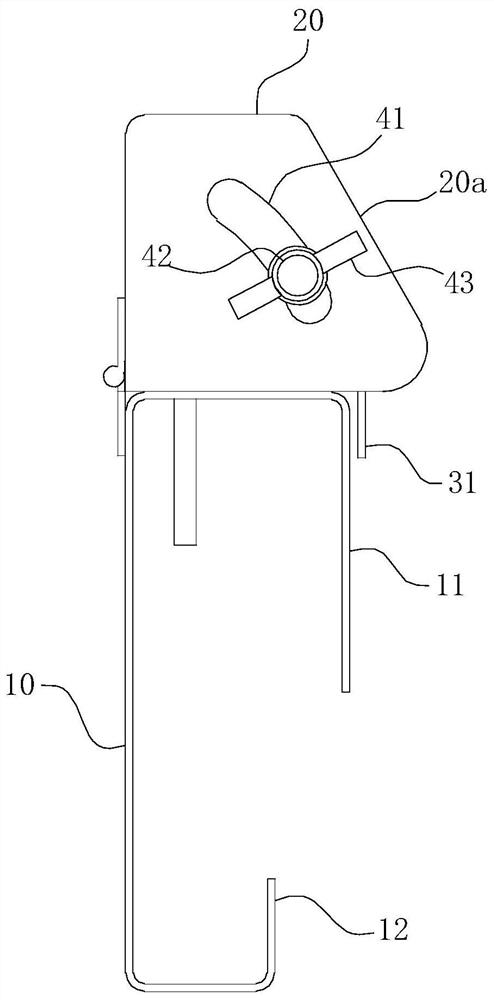

[0034] The specific components of the present invention include: power switch K 0 , power supply module 50, ignition and flameout protection module 60, pot detection sensor 30, constant flame solenoid valve DCF1, main fire solenoid valve DCF2, wind pressure switch K m and blower 70 etc. When assembling, such as figure 1 As shown, the wind pressure switch K m Installed at the air outlet of the blower 70, and connected with the ignition and flameout protection module 60; the ignition and flameout protection module 60 is then electrically connected to the ignition needle and the normal flame igniter through the first control circuit b and the second control circuit c respectively. Open flame solenoid valve DCF1. exist figure 1 In the specific embodiment, the pot detection sensor 30 and the power supply module 50 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com