A device and method for continuous whole enzymatic synthesis of diglycerides in a multi-liquid phase system

A technology for diglyceride and enzymatic synthesis, which is applied in sterilization methods, biochemical cleaning devices, biochemical equipment and methods, etc., can solve the problems of high cost, complicated reaction operation, difficult continuous production, etc. Material consumption, simplification of process flow, beneficial effect of extraction and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

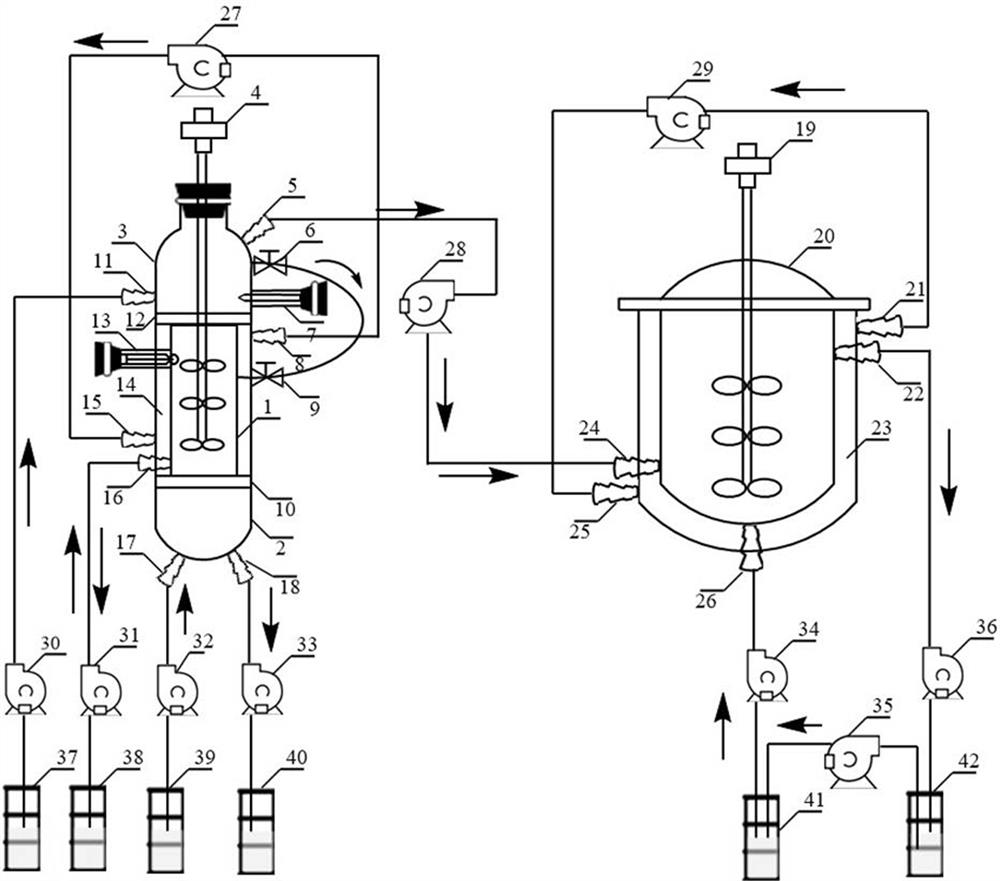

[0051] like figure 1 As shown, a multi-liquid phase system continuous enzymatic synthesis of diglycerides, including a hydrolysis device and an esterification device, the specific structure is as follows:

[0052] The hydrolysis device includes a device reaction zone 1, a dispersion buffer zone 2, a static zone 3, a first stirrer 4, an automatic potentiometric titrator burette 7, an automatic potentiometric titrator electrode head 13 and a first circulating water heating sleeve 14. Between the device reaction zone 1 and the dispersion buffer zone 2, there is a baffle plate 10 filled with several small holes, and between the device reaction zone 1 and the resting area 3, there is also a baffle plate 12 covered with several small holes. An oil sample inlet 17 and a lower phase solution outlet 18 are arranged at the lower part of the dispersion buffer zone 2 . In the standing area 3, the upper, middle and lower three liquid phase areas are divided. The upper liquid phase area is...

Embodiment 2

[0060] The method for continuously synthesizing diglycerides using the device of embodiment 1 may further comprise the steps:

[0061] Step (1): First prepare a 3L aqueous two-phase system, that is, according to the mass fraction of 20% (NH 4 ) 2 SO 4 , Dissolve 20% PEG600 and 60% water and mix well to prepare in a 3L separatory funnel. Place the separatory funnel in an incubator at 37°C for 24 hours. After being clearly separated, the two-phase solution was passed through a 0.45 μm filter membrane to remove impurities to obtain the upper phase PEG600 and the lower phase (NH 4 ) 2 SO 4 solution.

[0062] Step (2): Turn on the first circulating water heat pump 27, add 5g Lipase AY30 enzyme and 10mL [BMIM]BF to 100mL upper phase PEG600 4 , 300mL lower phase Na 2 SO 4 The solution is passed into the static zone 3 under the condition of heating and stirring to make it full of the dispersion buffer 2, and then the PEG600 solution containing enzyme is passed into the reactio...

Embodiment 3

[0066] The method for continuously synthesizing diglycerides using the device of embodiment 1 may further comprise the steps:

[0067] Step (1): First prepare a 3L aqueous two-phase system, that is, according to the mass fraction of 20% PEG600, 15% Na 2 SO 4 , 65% of the water was dissolved and mixed evenly for preparation in a 3L separatory funnel, and the separatory funnel was placed in an incubator at 37°C for 24 hours. After clear separation, the two-phase solution was passed through a 0.45 μm filter membrane to remove impurities to obtain the upper phase PEG600 and the lower phase Na 2 SO 4 solution.

[0068] Step (2): Turn on the first circulating water heat pump 27, and add 7.5g LipaseTL100L enzyme into 150mL upper phase PEG600. 300mL lower phase Na 2 SO 4 Under the conditions of heating and stirring, pass it into the static zone 3 to make it full of the dispersion buffer 2, and then pass the enzyme-containing PEG600 solution into the reaction zone 1, the stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com