Demulsifier and its preparation method

A technology of demulsifier and polyether, which is applied in the field of demulsifier and its preparation, can solve the problems of unsatisfactory dehydration effect of demulsifier flocculation ability and coalescence ability, poor dehydration effect of crude oil at low temperature, and poor adaptability of crude oil products, etc. The effect of industrialized promotion of production, fast oil-water separation rate and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

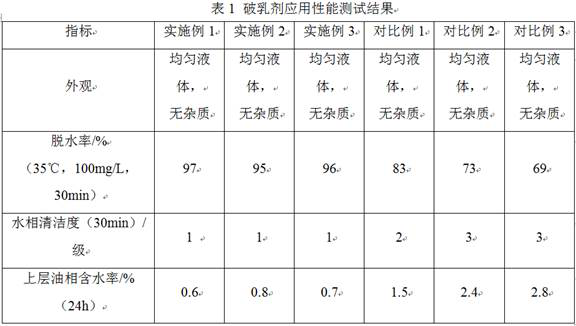

Examples

Embodiment 1

[0047] The demulsifier described in this embodiment 1, in terms of mass percentage, consists of 22% silicone oil modified phenolic amine resin polyether demulsifier, 35% acrylic modified triblock phenolic amine resin polyether demulsifier, 6% Ionic liquid, 0.5% myristamidopropyl hydroxypropyl sulfobetaine, 14% diethylene glycol mono-n-butyl ether and the balance water.

[0048] in:

[0049] The ionic liquid is bromo-1-octyl-2,3-dimethylimidazole.

[0050] Bromo-1-octyl-2,3-dimethylimidazole is added as an ionic liquid, which can quickly reach the oil-water interface and reduce the tension of the oil-water interface.

[0051] The preparation method of described silicone oil modified phenolic resin polyether demulsifier, consists of the following steps:

[0052] (1) Add phenolic amine resin and alkali catalyst to the autoclave, stir and heat up to 95°C, vacuumize and replace with nitrogen, control the pressure at -0.15MPa, continue to heat up to 127°C, feed propylene oxide for...

Embodiment 2

[0081] The demulsifier described in this embodiment 2, in terms of mass percentage, consists of 20% silicone oil modified phenolic amine resin polyether demulsifier, 33% acrylic modified triblock phenolic amine resin polyether demulsifier, 5% Ionic liquid, 0.6% myristamidopropyl hydroxypropyl sulfobetaine, 12% diethylene glycol mono-n-butyl ether and the balance water.

[0082] in:

[0083] The ionic liquid is bromo-1-octyl-2,3-dimethylimidazole.

[0084] Bromo-1-octyl-2,3-dimethylimidazole is added as an ionic liquid, which can quickly reach the oil-water interface and reduce the tension of the oil-water interface.

[0085] The preparation method of described silicone oil modified phenolic resin polyether demulsifier, consists of the following steps:

[0086] (1) Add phenolic amine resin and alkali catalyst to the autoclave, stir and raise the temperature to 90°C, vacuumize and replace with nitrogen, control the pressure at -0.20MPa, continue to heat up to 125°C, feed propy...

Embodiment 3

[0115] The demulsifier described in this Example 3, in terms of mass percentage, is composed of 25% silicone oil modified phenolamine resin polyether demulsifier, 30% acrylic modified triblock phenolamine resin polyether demulsifier Emulsion, 8% ionic liquid, 0.7% tetradecamidopropyl hydroxypropyl sulfobetaine, 15% diethylene glycol mono-n-butyl ether and balance water.

[0116] in:

[0117] The ionic liquid is bromo-1-octyl-2,3-dimethylimidazole.

[0118] Bromo-1-octyl-2,3-dimethylimidazole is added as an ionic liquid, which can quickly reach the oil-water interface and reduce the tension of the oil-water interface.

[0119] The preparation method of the silicone oil-modified phenolamine resin polyether demulsifier comprises the following steps:

[0120] (1) Add the phenolamine resin and alkali catalyst into the autoclave, stir and heat up to 92°C, vacuumize and replace with nitrogen, control the pressure at -0.20MPa, continue to heat up to 127°C, feed propylene oxide for r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com